Induction regulator block

a technology of induction regulator and manifold, which is applied in the direction of combustion air/fuel air treatment, fuel thermal treatment, air intake for fuel, etc., can solve the problems of increased cost and likelihood of mechanical failure, complex design, and difficult retrofitting, so as to improve the efficiency of the internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

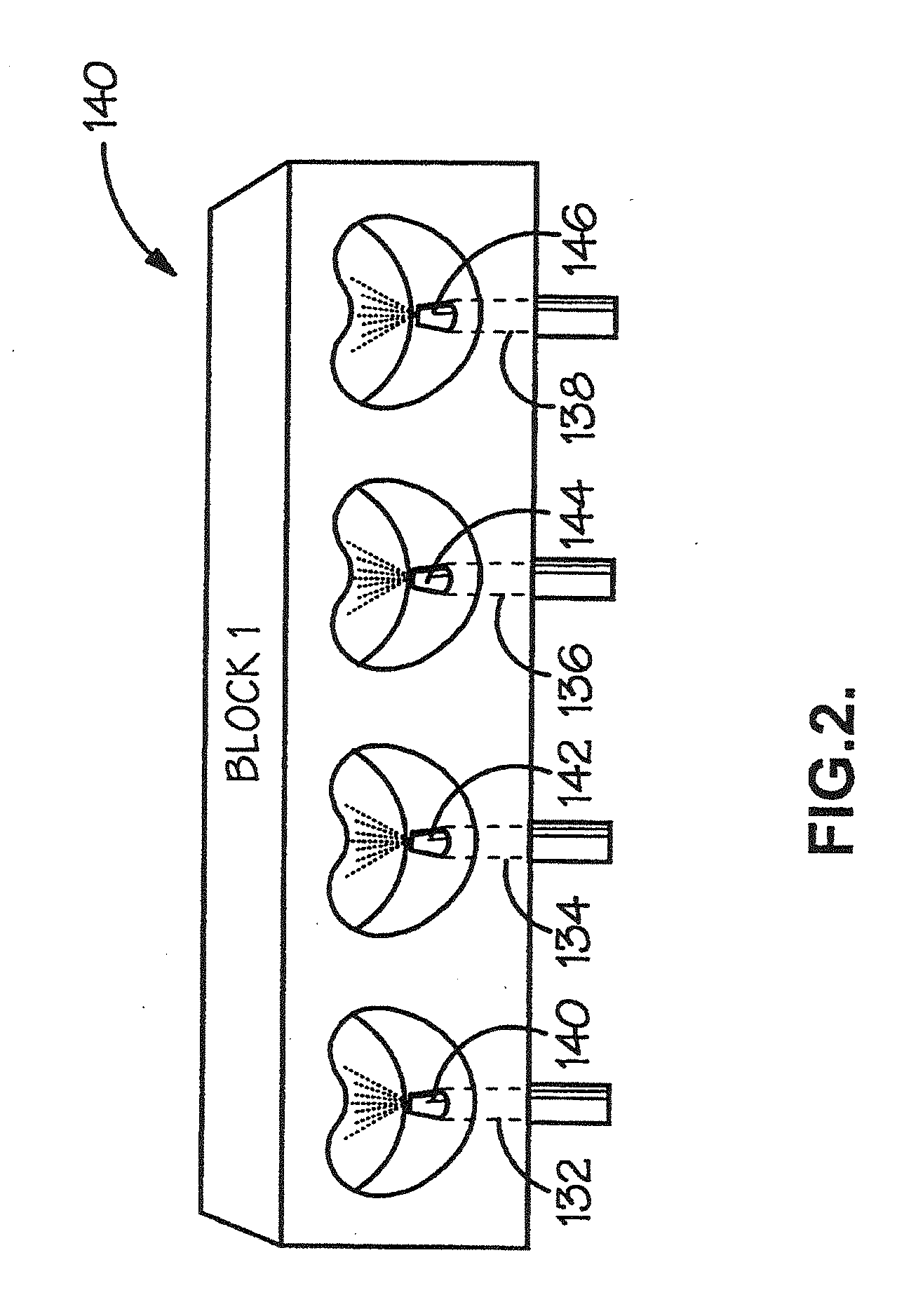

[0069]A Ford Focus 1.6 engine was tested to ascertain the emissions and torque of an engine incorporating the manifold block of the present invention inserted between a conventional manifold and a conventional cylinder head. These tests sought to identify change in emissions, BHP and torque which occurred when different sized blocks in accordance with the invention were fitted on the vehicle.

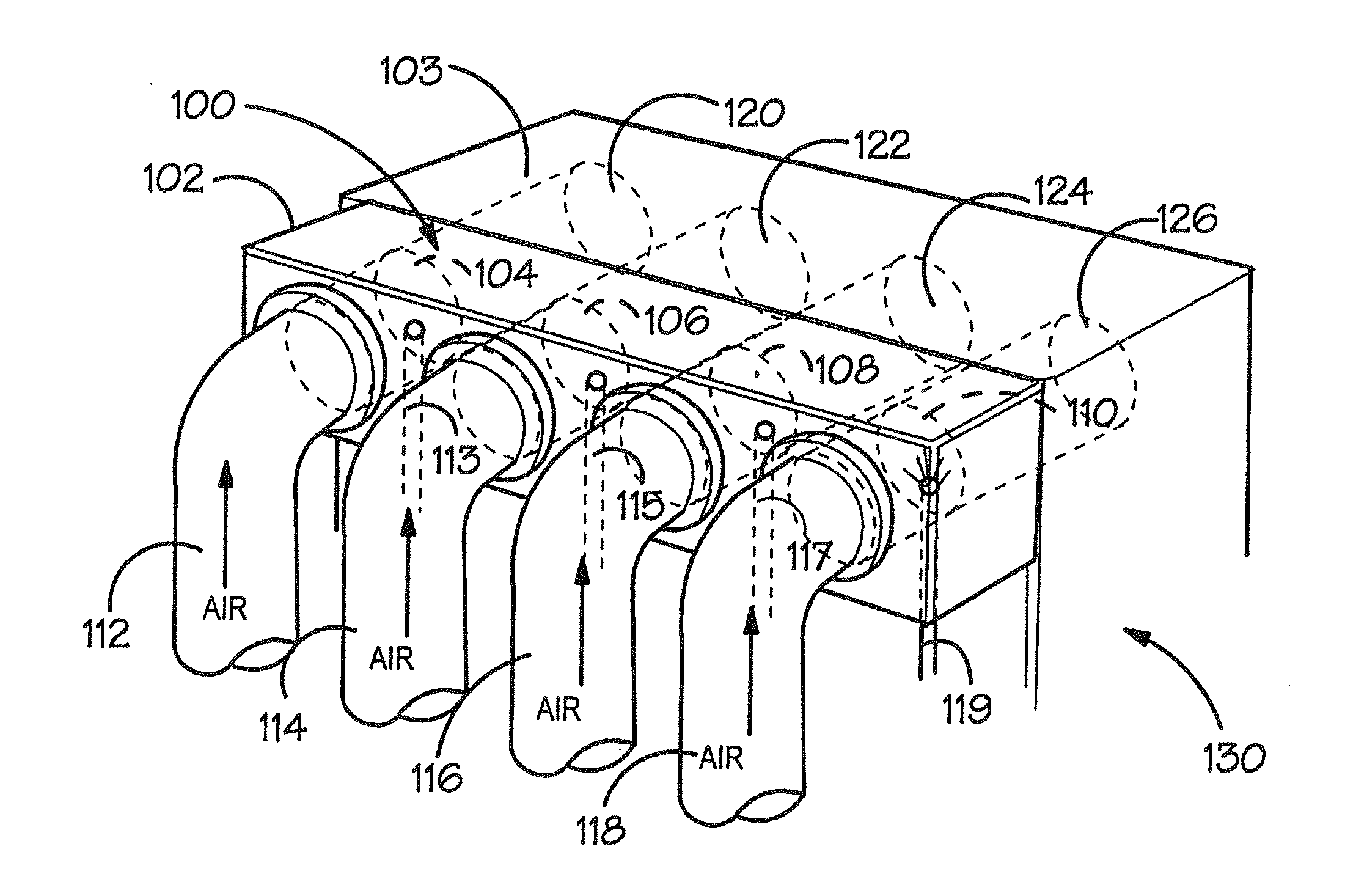

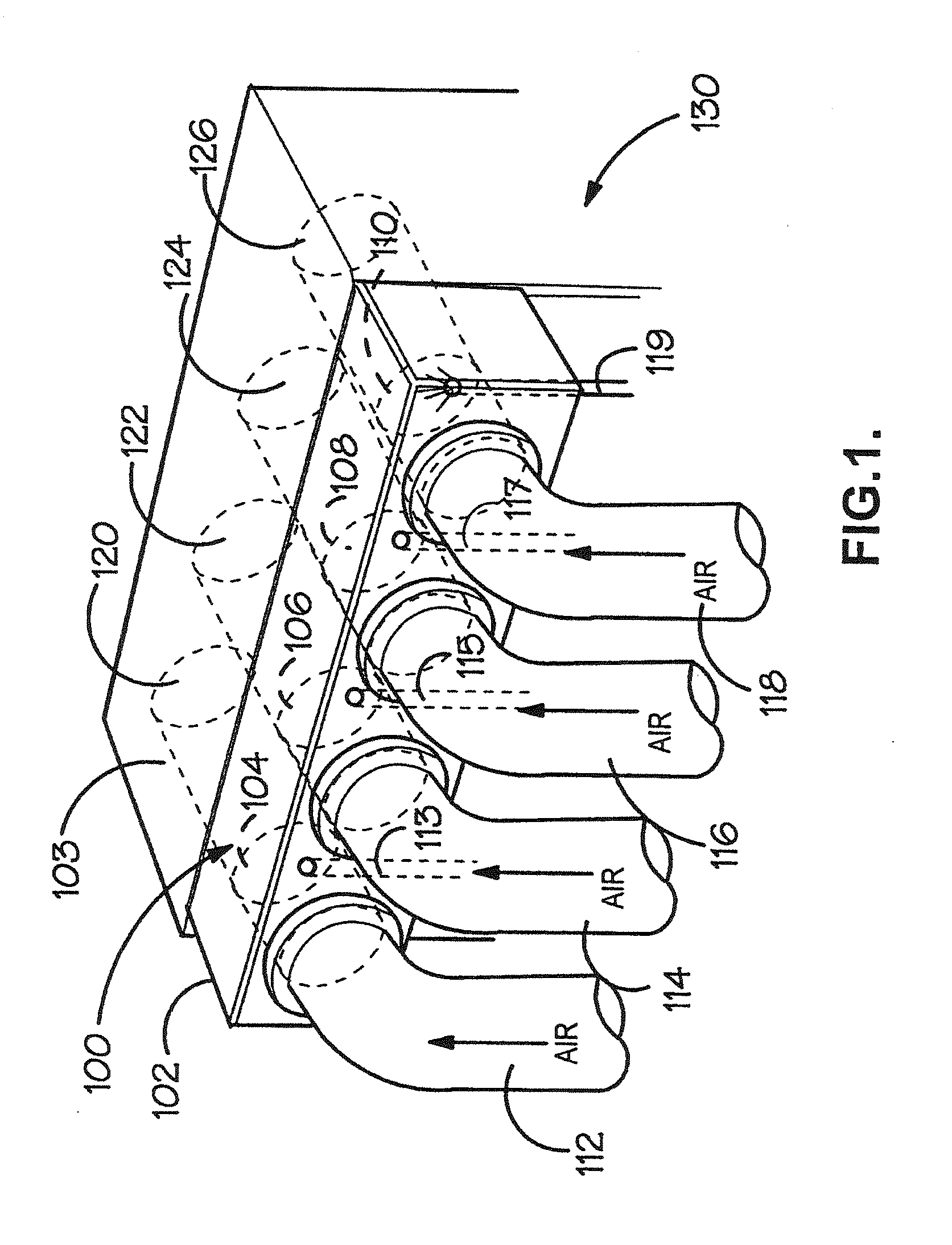

[0070]In order to fit the new block the conventional manifold, fuel rail, and injector were first removed, exposing the cylinder head. The block of the invention was then fitted on the cylinder head. For the purpose of these experiments it was in some cases found necessary to secure a gasket between the cylinder head and the block to make the connection airtight. In this case the gasket was fitted to the underside of the manifold block. The manifold block is then carefully placed on top of the cylinder head and the original inlet manifold is then fitted on top of the manifold block, again if nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com