Method and Device for Generating and Storing Hydrogen

a technology of hydrogen generation and storage, applied in the direction of electrolysis process, electrolysis components, reactant parameter control, etc., can solve the problems of metal hydride being soon spoiled, the danger of system blocking by freezing is negligible, and the time interval for a replacement of chemical absorbers is larg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

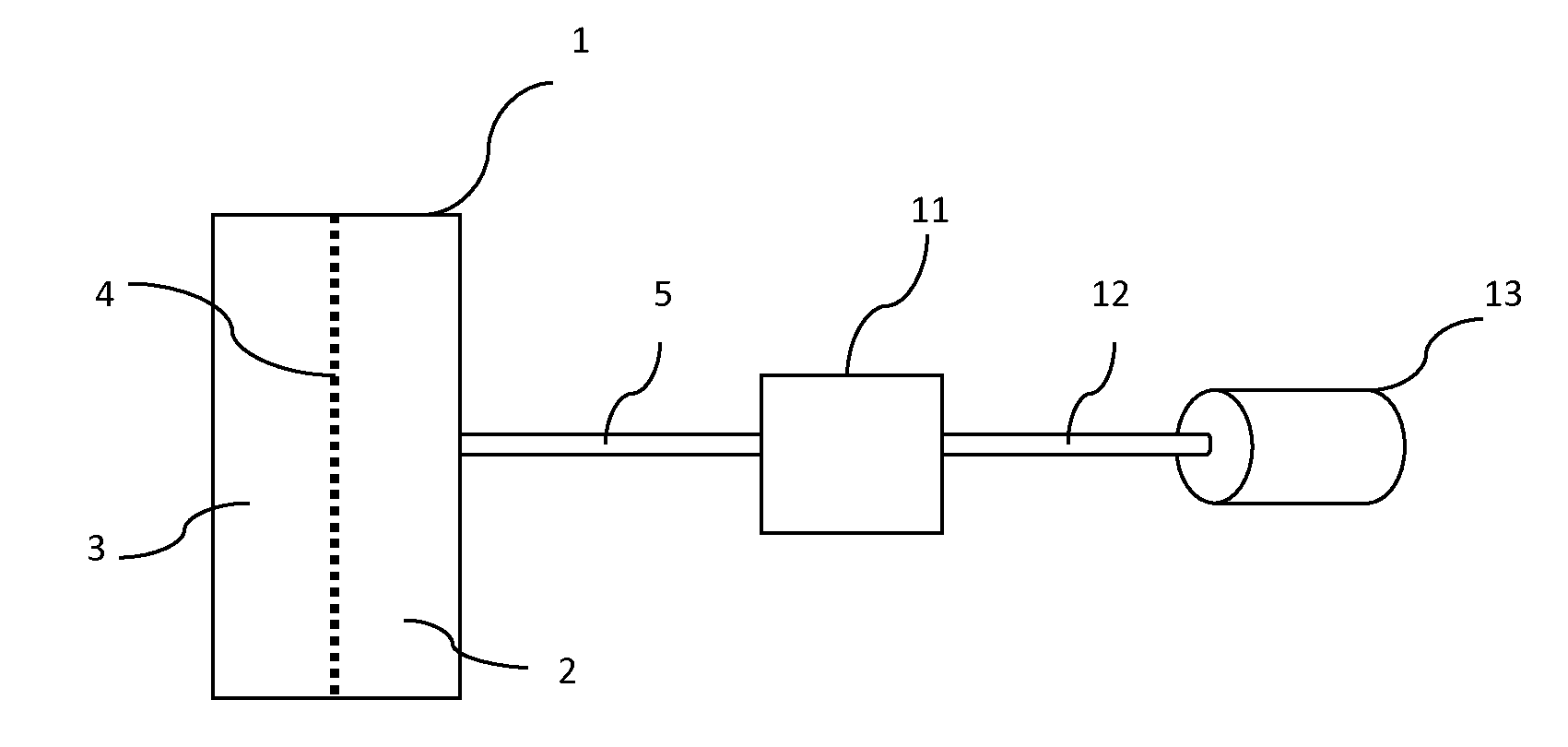

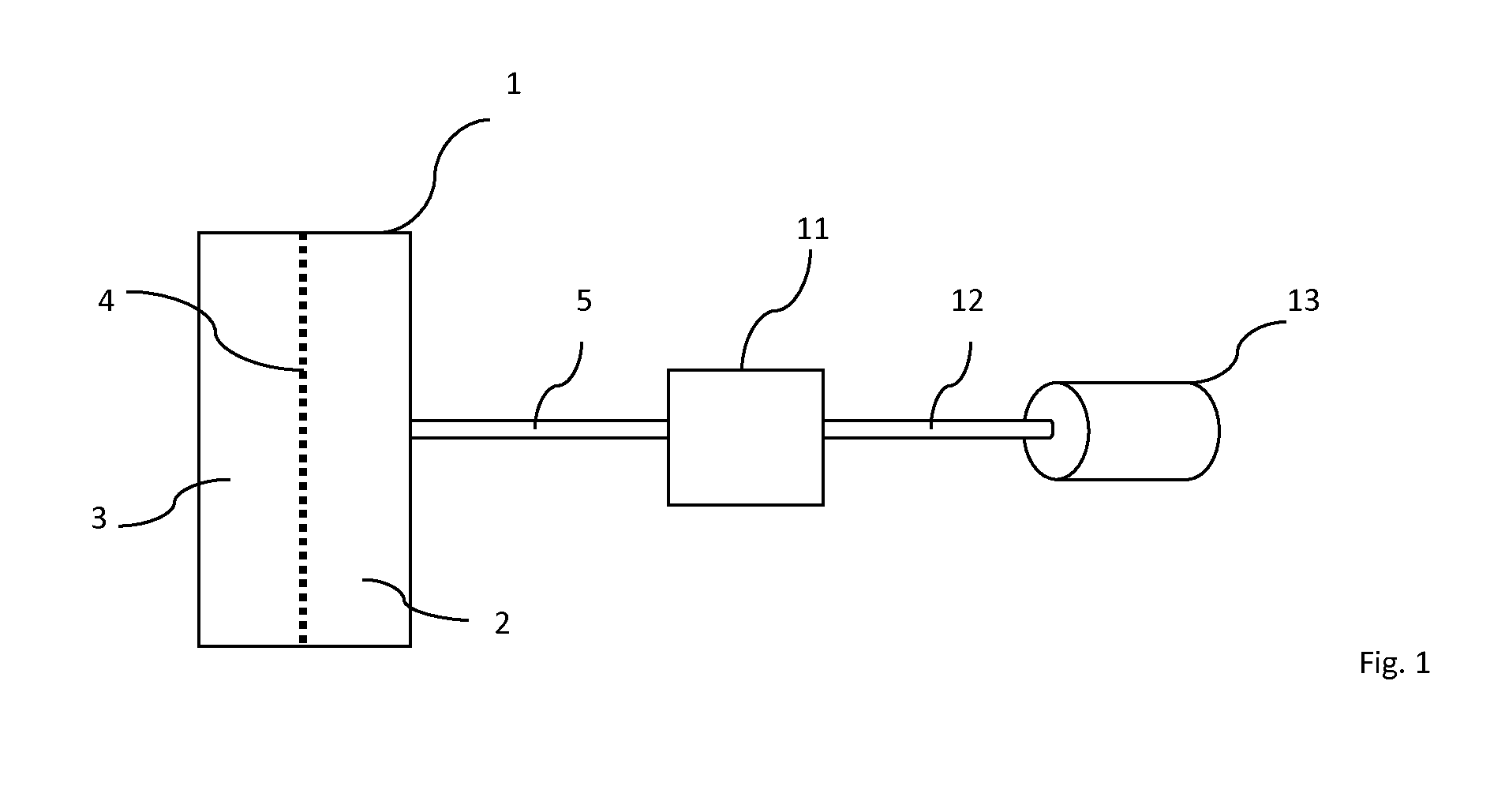

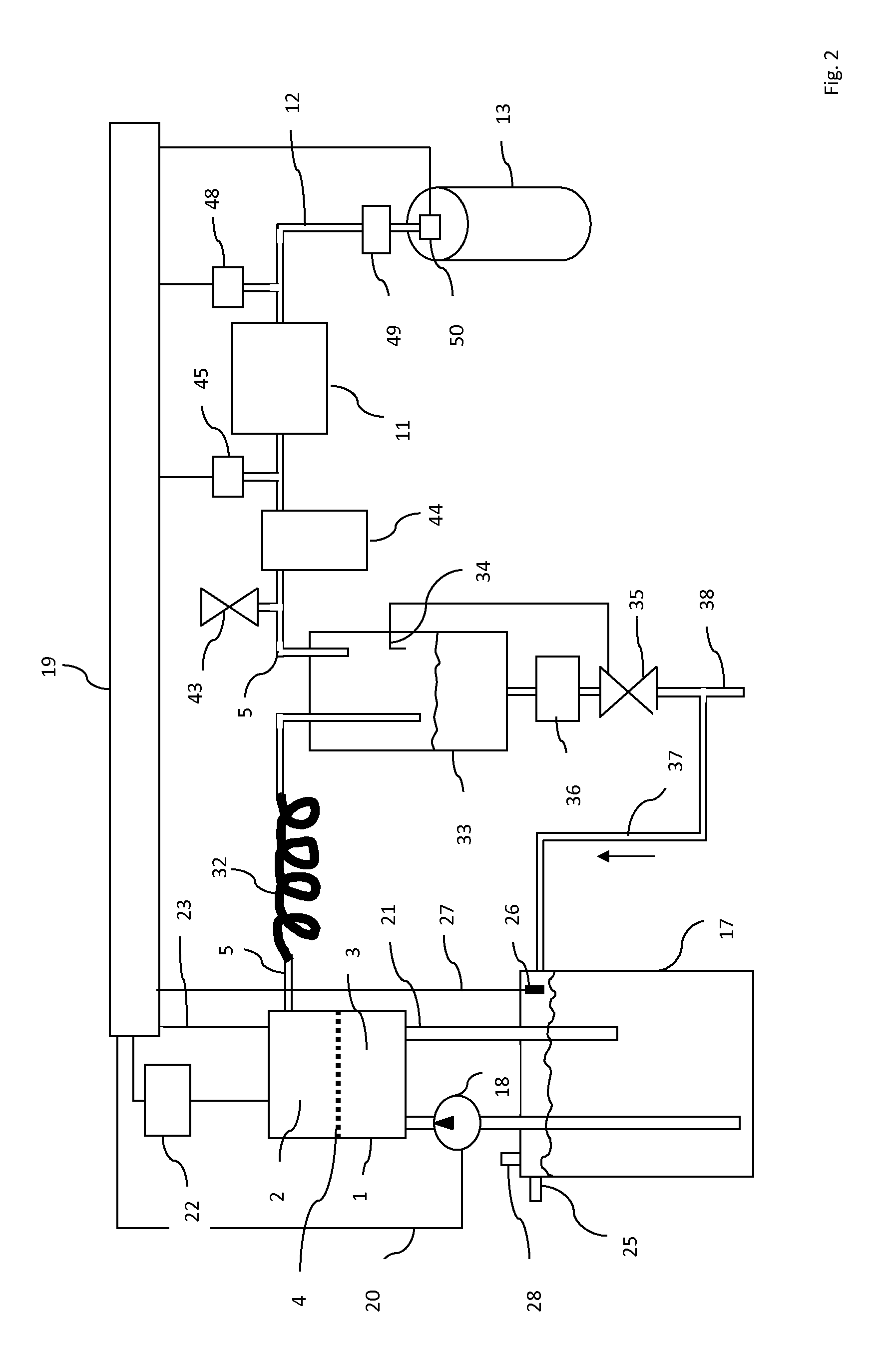

[0014]According to FIG. 1, in a stack of PEM electrolysis cells 1, in the drawing for simplicity shown as a single cell, a cathode compartment 2 and an anode compartment 3 are separated by a polymer electrolyte membrane (PEM) 4. To the anode compartment 3, in operation water is added. The compartments contain electrodes to which dc is supplied, whereupon at the anode in compartment 3 oxygen is produced and at the cathode in compartment 2 hydrogen is produced, which is the used product of the electrolysis cells 1. The hydrogen is generated under a pressure of at least 1 MPa, preferably 2.5 to 4 MPa under which pressure hardly any water vapour, escapes with the hydrogen. In this case, hardly any contaminating water will emerge in the cathode compartment 2.

[0015]From this compartment 2, a first conduit 5 conducts the hydrogen, nearly without any water content, under the original high pressure to a pressure adjusting device 11, which, in the described example, is a pressure reduction va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| counter pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com