Methods for producing phase stable, reduced acid biomass-derived pyrolysis oils

a biomass-derived pyrolysis oil, phase stable technology, applied in the direction of biofeedstock, liquid carbonaceous fuels, petroleum industry, etc., can solve the problems of limiting its utilization as fuel/biofuel, high oxygenation of organic liquids with properties, and low energy density and susceptibility to increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011]The following detailed description of the invention is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background of the invention or the following detailed description of the invention.

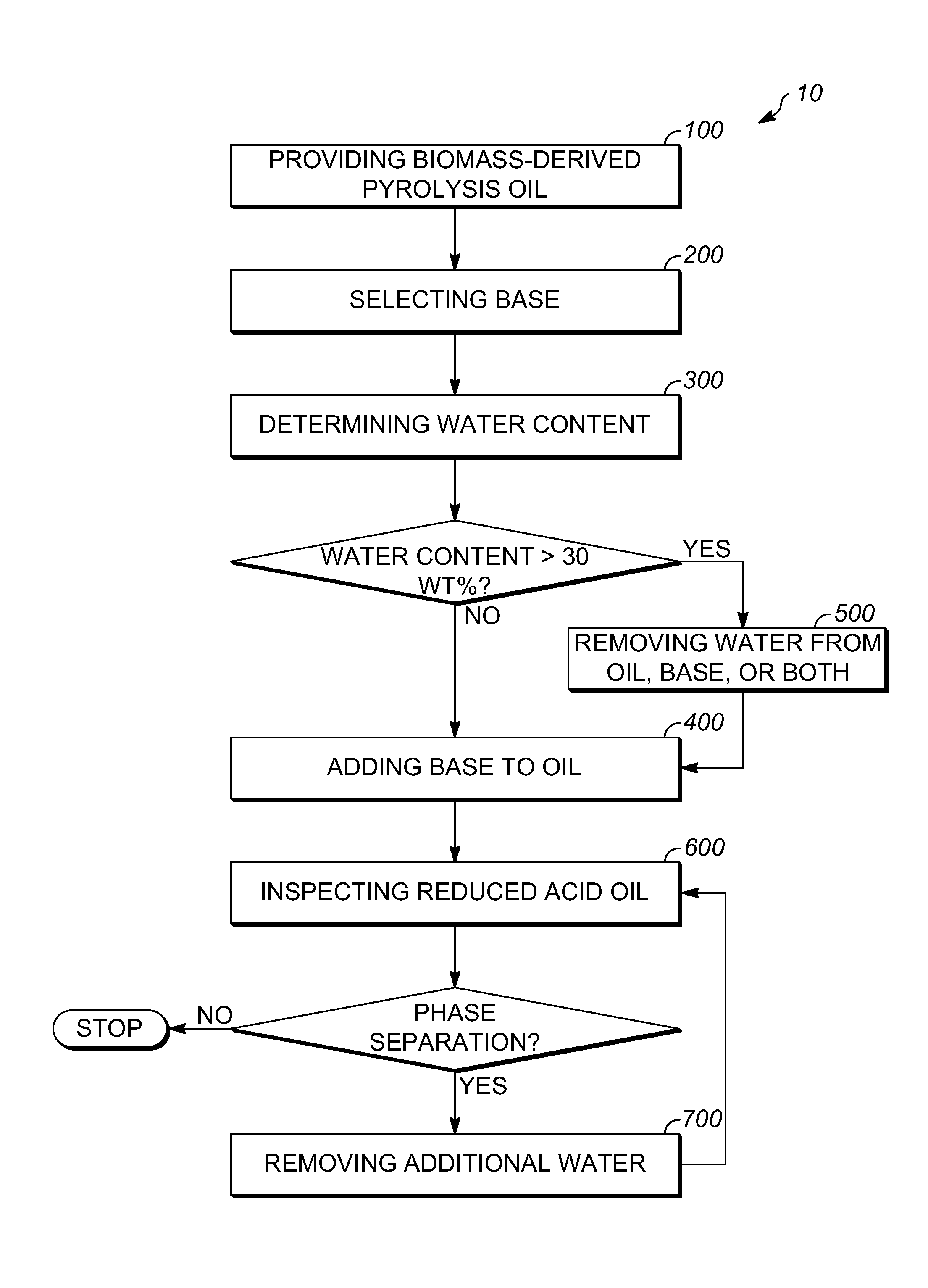

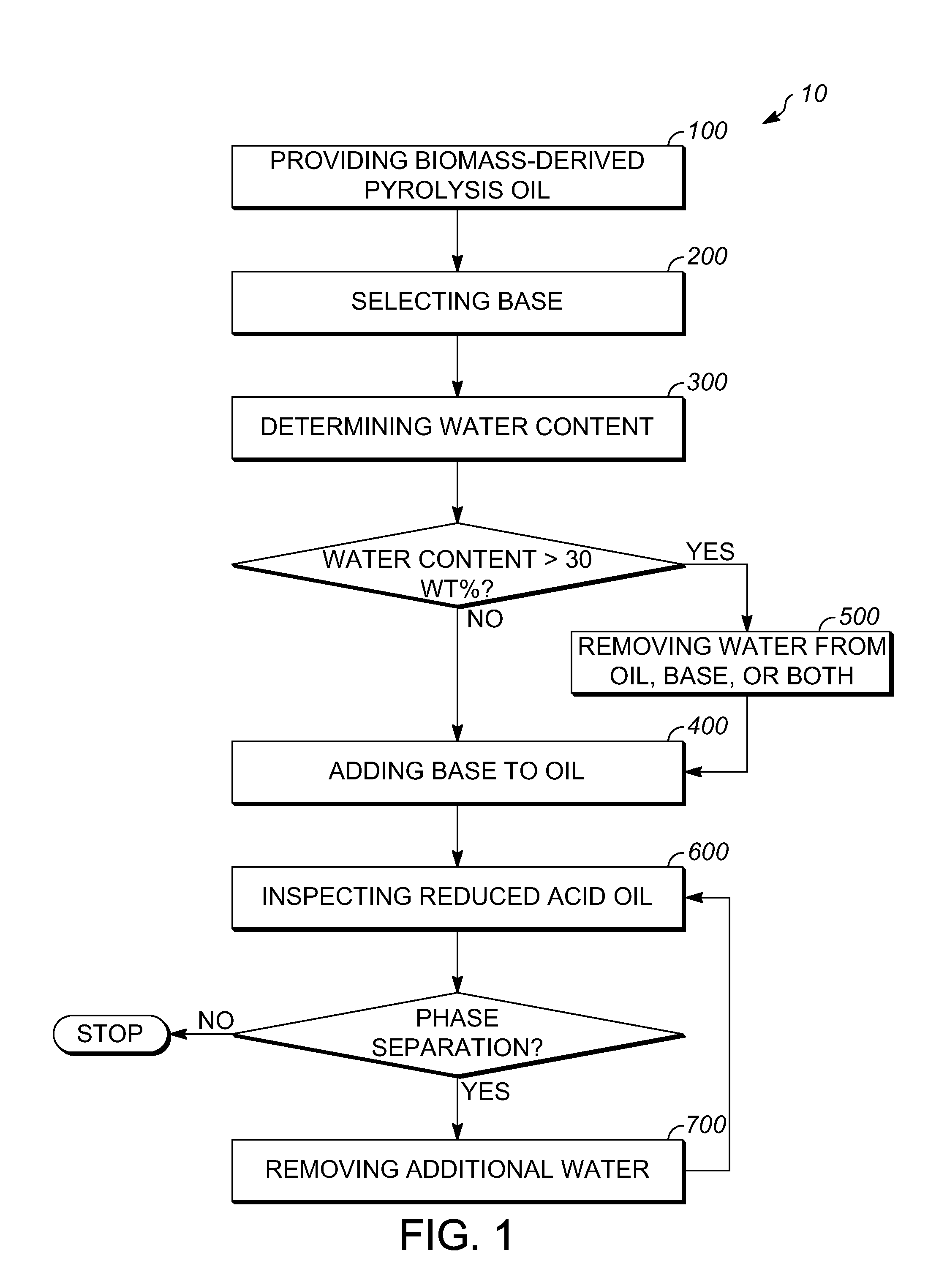

[0012]Various exemplary embodiments of the present invention are directed to a method for producing phase stable, reduced acid biomass-derived pyrolysis oils. It should be appreciated that while the oil produced according to exemplary embodiments of the present invention is generally described herein as a “reduced acid biomass-derived pyrolysis oil”, this term generally includes any oil produced having a lower acidity than the conventional biomass-derived pyrolysis oil from which it is derived. As noted previously, “phase stability” as used herein means the ability of the oil to resist changes in chemical composition and maintain homogeneity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com