Cascaded condenser for multi-unit geothermal orc

a geothermal orc and condenser technology, applied in the field of vapor expansion systems, can solve the problem of proportional parametric power cost of this process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

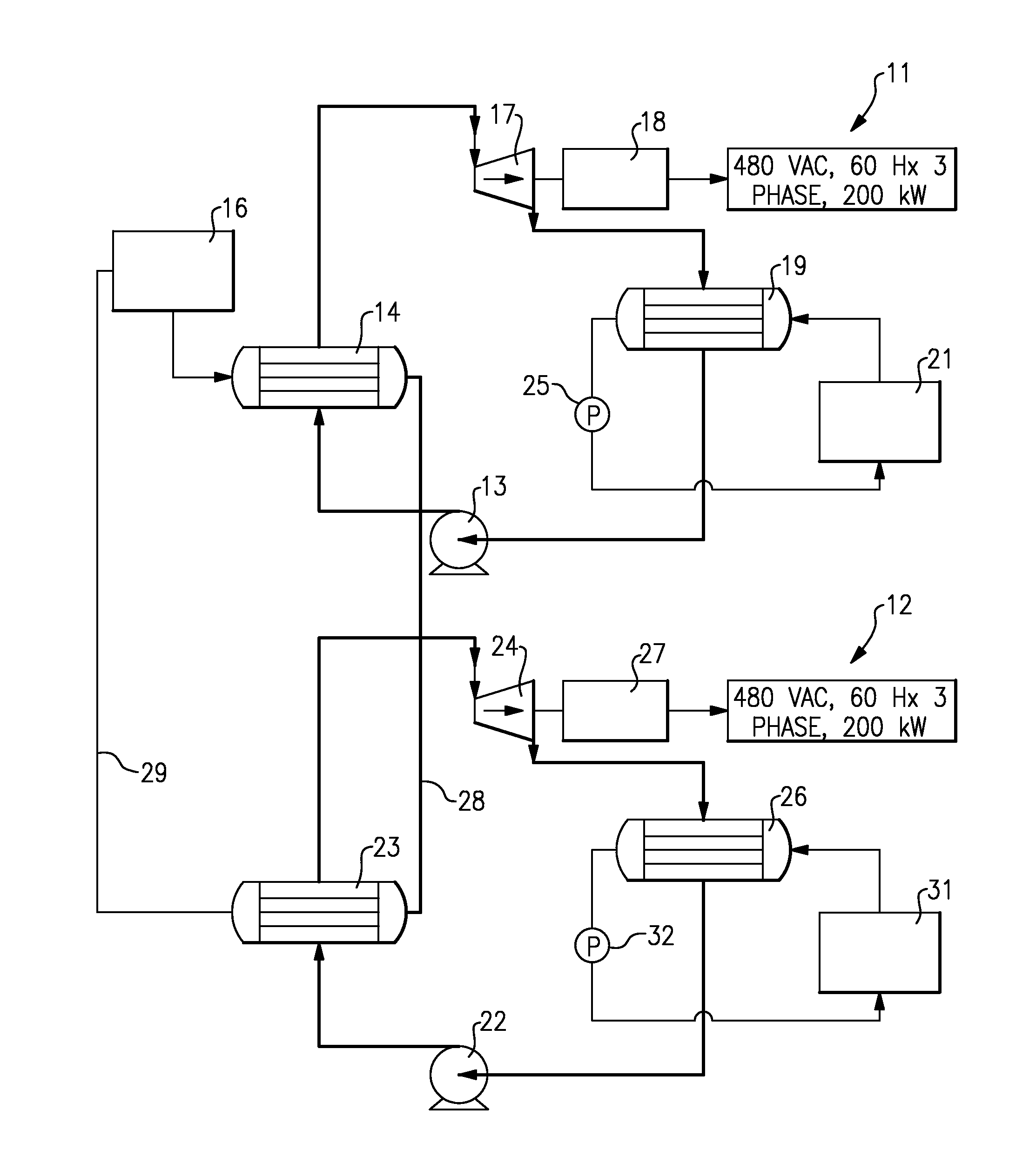

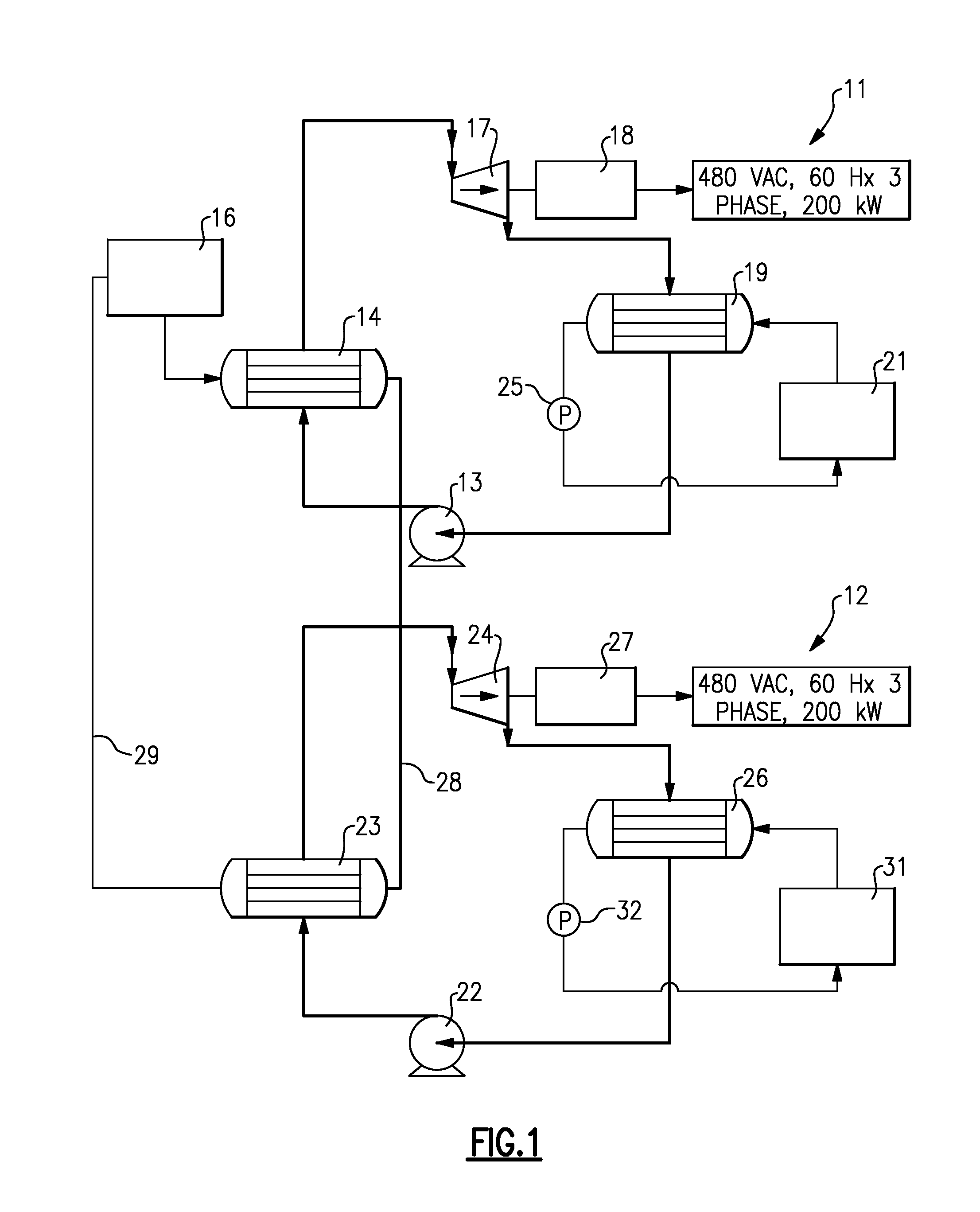

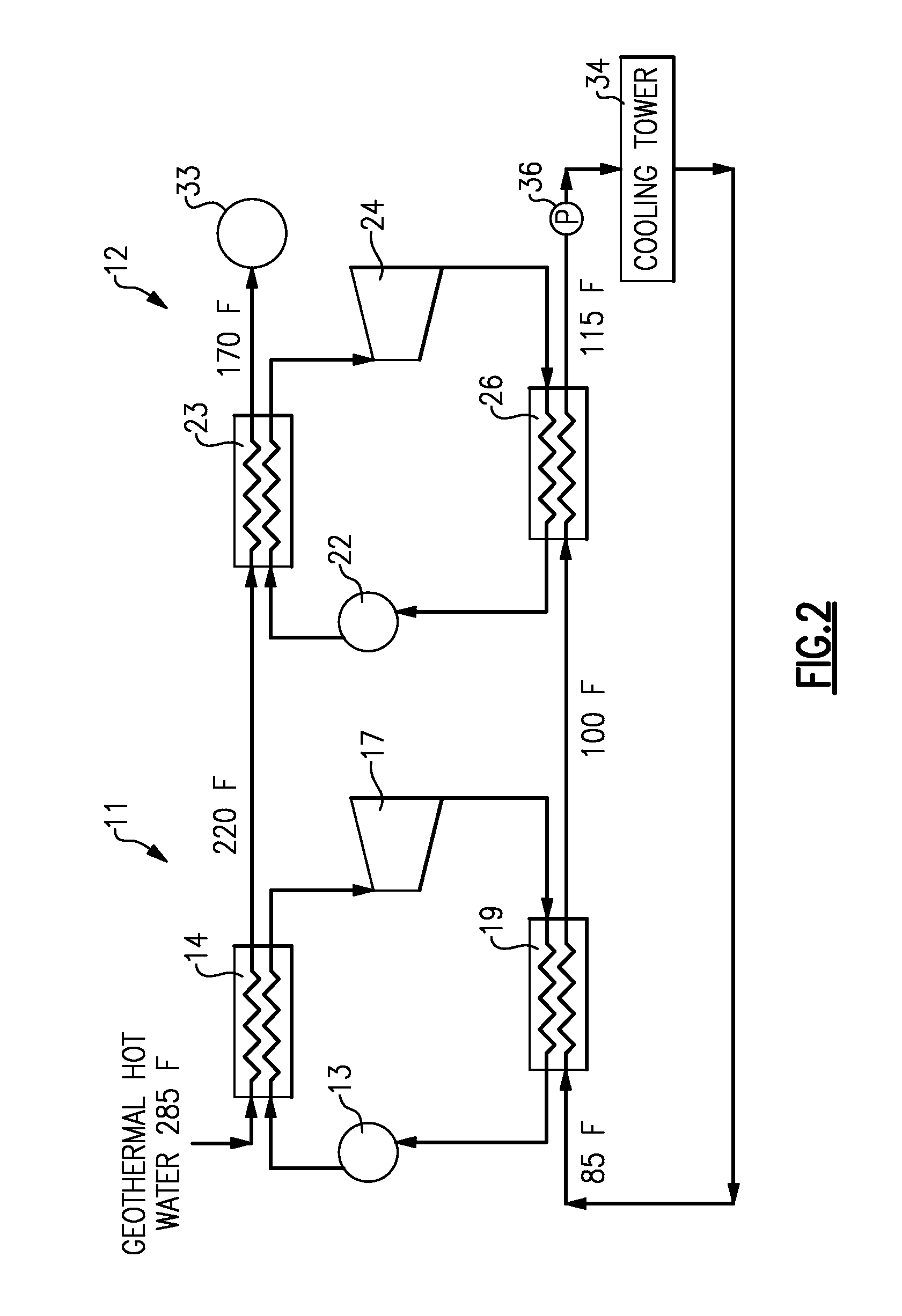

[0010]Shown in FIG. 1 is a pair of organic rankine cycle systems 11 and 12 arranged to operate in accordance with the prior art. The first ORC system 11 includes, in serial, working fluid flow relationship, a pump 13, an evaporator 14, a turbine 17, and a condenser 19. The working fluid is any suitable organic refrigerant such as R-245fa. The refrigerant is pumped by the pump 13 to an evaporator 14 where it is heated by hot water from a geothermal heat source 16. The resulting superheated vapor then passes to the turbine 17 for driving a generator 18 to produce electrical power. The resulting lower energy vapor then passes to the condenser 19 where it is condensed by giving up heat to the cooling water circulating through the condenser 19 from a heat sink 21. The condensate then passes to the pump 13 to complete the cycle. The heat sink 21 may be a cooling tower or a pond or river, to the condenser 19, and a pump 25 drives the cooling fluid to the heat sink 21.

[0011]The second ORC s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com