Thin Glass for Touch Panel Sensors and Methods Therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

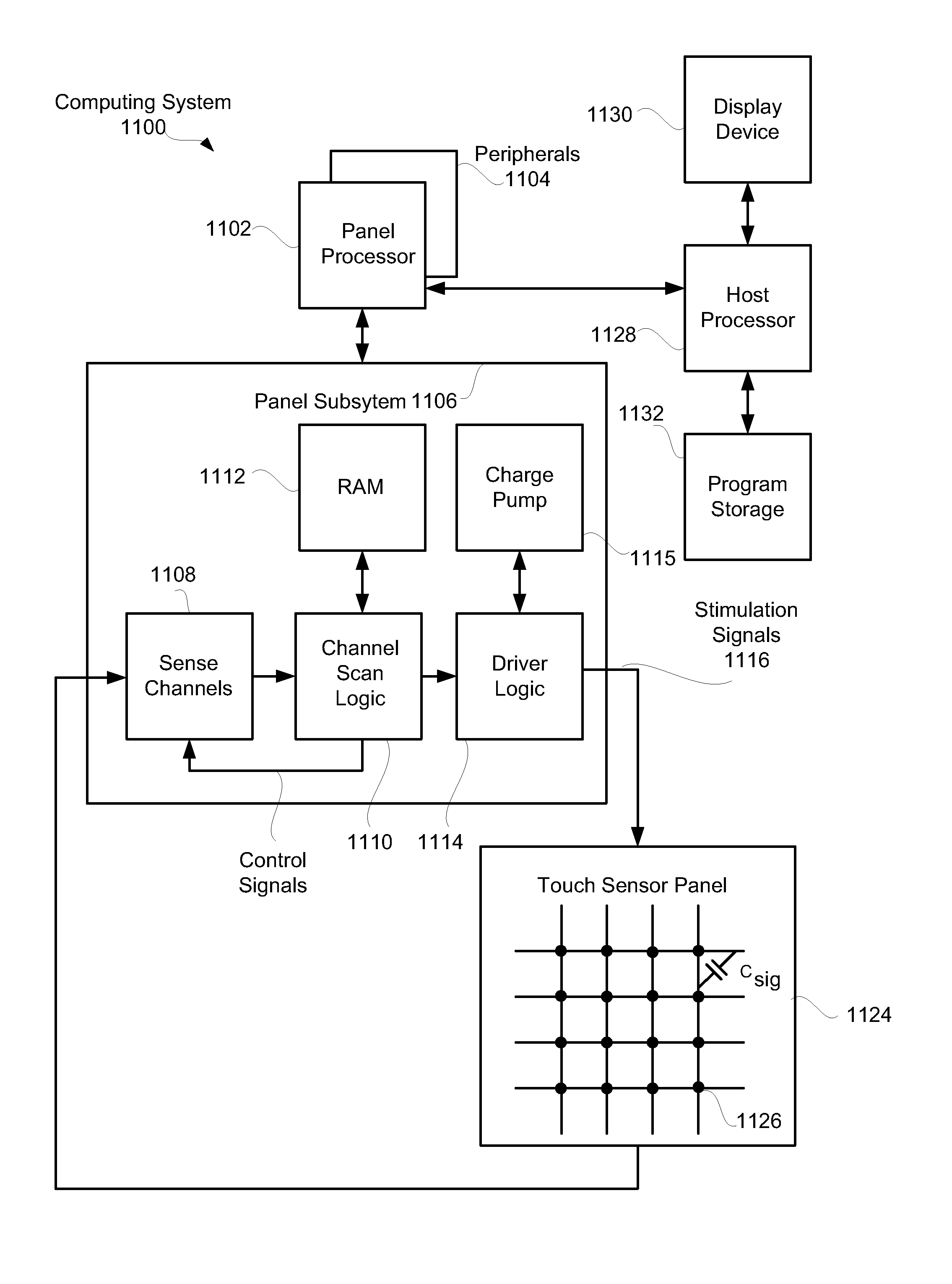

[0028]Improved techniques are disclosed for fabrication of touch panels using thin sheet glass. Thin touch sensor panels each having a thickness of substantially less than approximately one-half millimeter can be produced. A thin mother glass sheet having a thickness of substantially less then approximately one half millimeter may be used. The thin mother glass sheet may be chemically strengthened and laser scribed. The thin mother glass sheet may be singulated into the thin touch sensor panels.

[0029]Embodiments are discussed below with reference to FIGS. 1-11. However, those skilled in the art will readily appreciate that the detailed description given herein with respect to these figures is for explanatory purposes, as the invention extends beyond these limited embodiments.

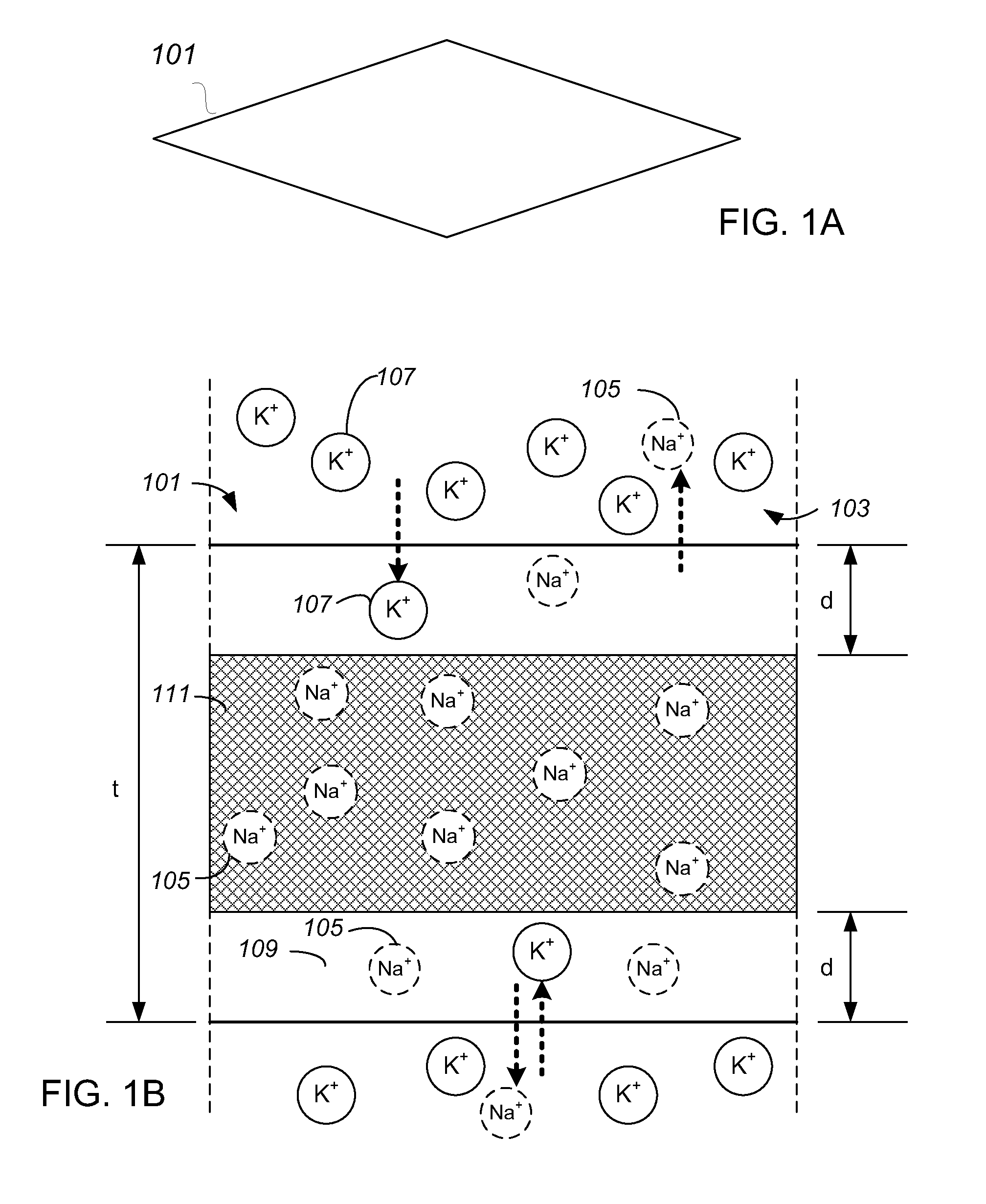

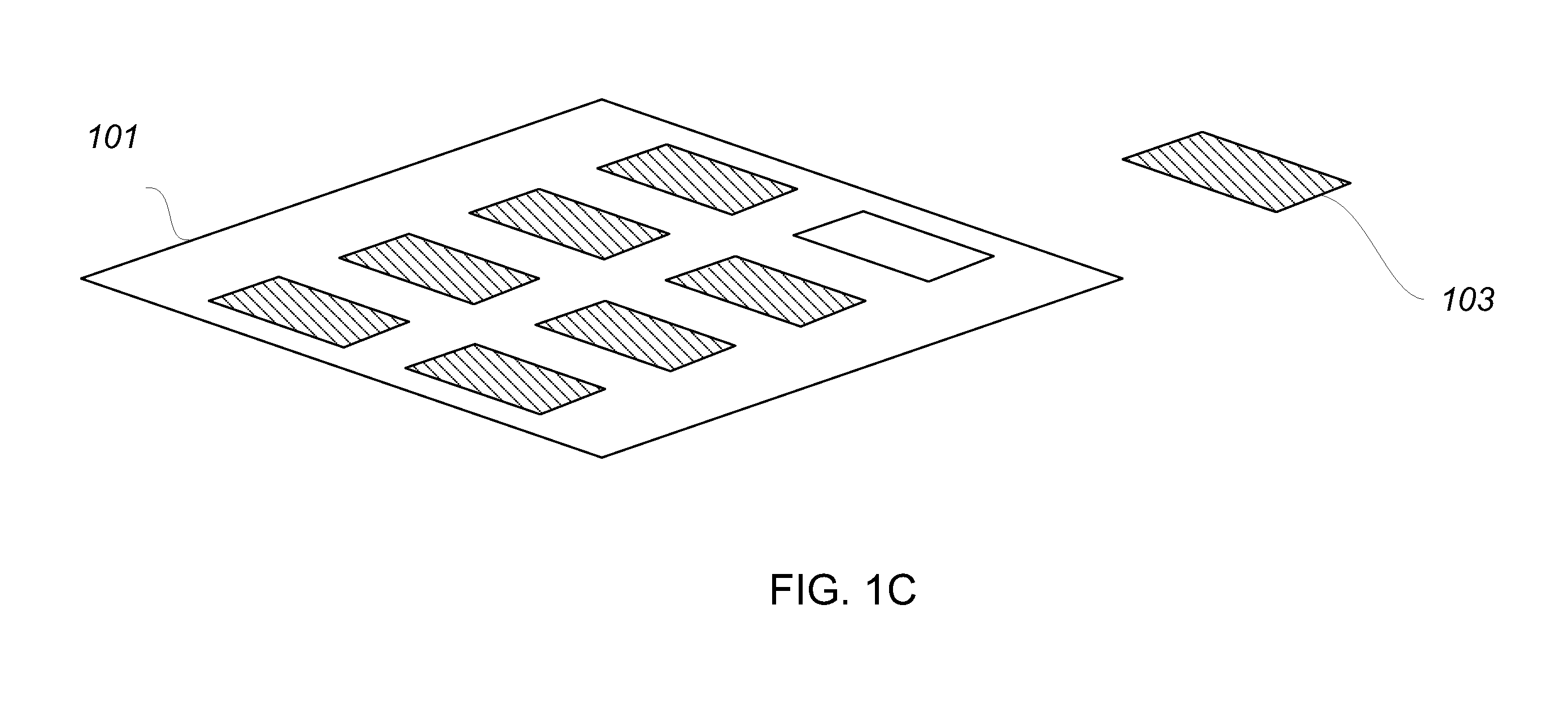

[0030]FIGS. 1A-1C show various views of processing the thin mother glass sheet into the thin touch sensor panels. FIG. 1A shows perspective view, and FIG. 1B shows a detailed partial cross sectional view of a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com