Pivoting Pipe Handler for Tender Assisted Drilling Rigs

a technology of pipe handlers and drilling rigs, which is applied in the direction of drilling rods, drilling accessories, earthwork drilling and mining, etc., can solve the problems of not having tubular storage or staging capability, not being able to deliver tubulars horizontally over the drill rig floor, and not being able to facilitate pick up and lay down operations, so as to facilitate safe orientation and position. , the effect of facilitating the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

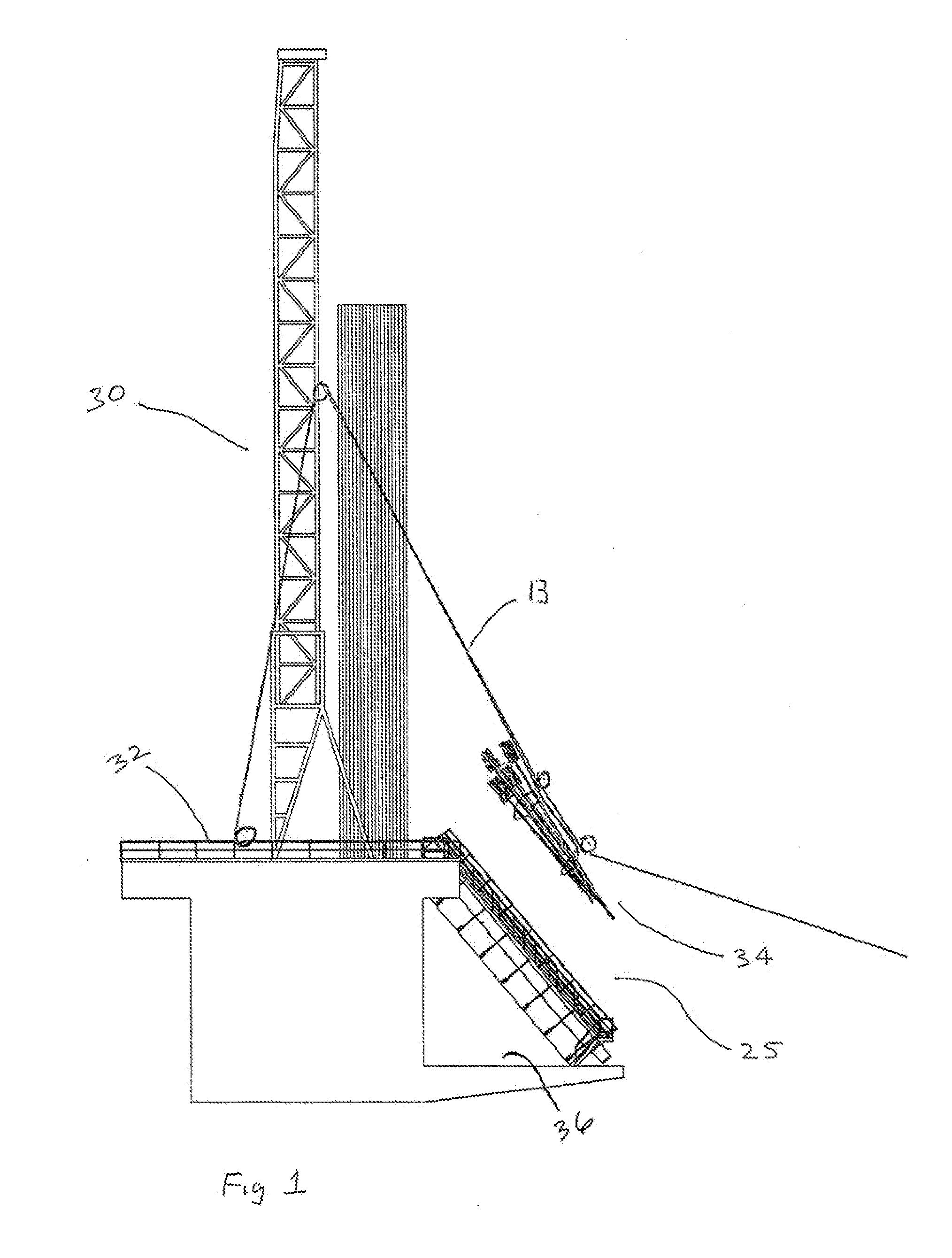

[0025]A pivoting pipe handler for tender assisted drilling rigs is provided. Referring to FIG. 1, pivoting pipe handler 25 is shown disposed on drilling rig 30 at an incline between drilling rig floor 32 and lower platform 36. In this illustration, tubulars 34 are being delivered to pipe handler 25 from a tender (not shown) using high-line mechanism 13, which is a well-known mechanism to those skilled in the art.

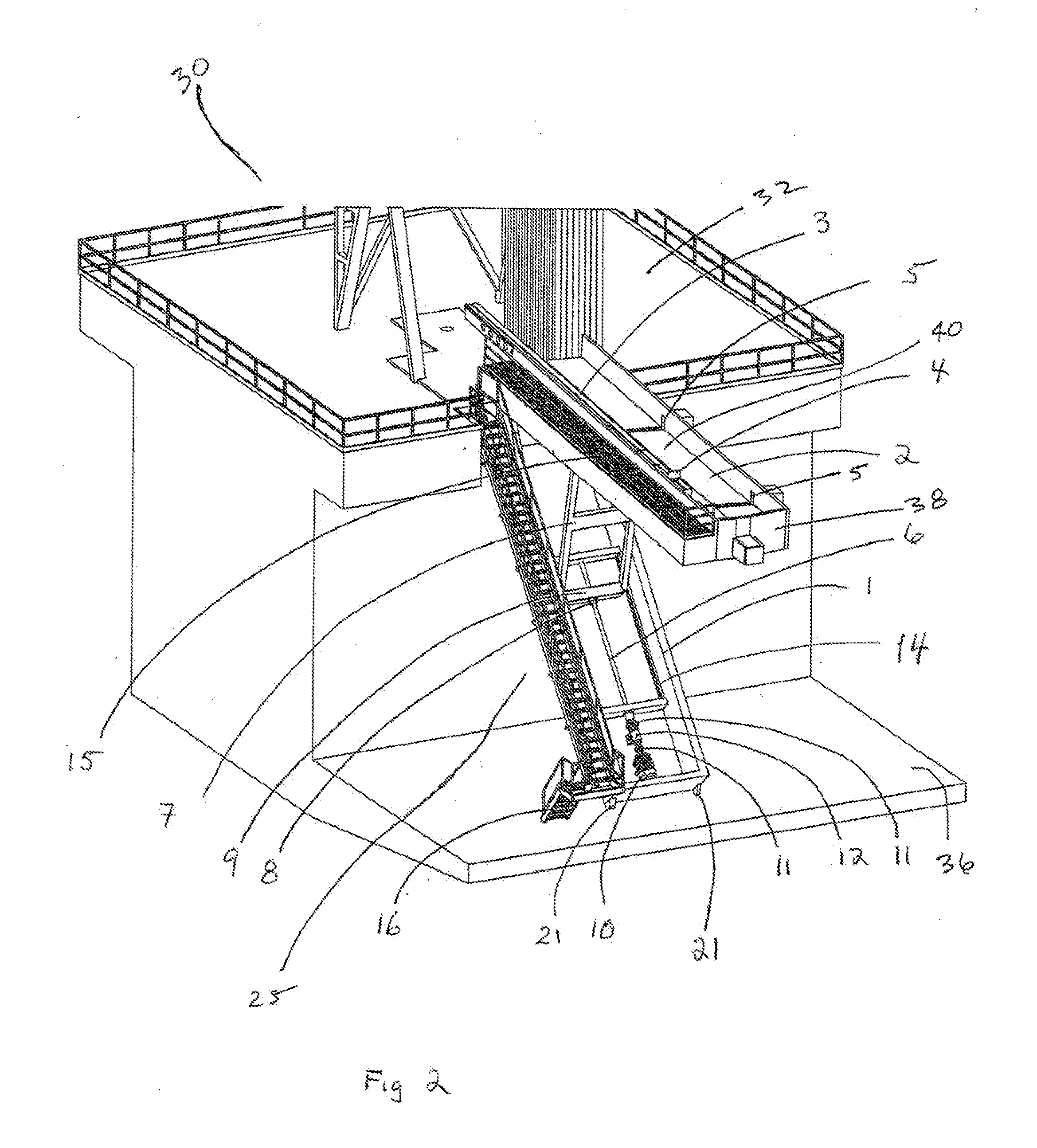

[0026]Referring to FIG. 2, one embodiment of pipe handler 25 is shown with V-door 2 in a horizontal position. In this embodiment, pipe handler 25 can comprise main support structure 1 further comprising V-door 2 pivotally attached to the upper end of main support structure 1. Lower end 38 of V-door 2 can be raised with an elevating mechanism or means for elevating lower end 38. In some embodiments, the elevating mechanism can comprise lift arm 7 pivotally attaching at an upper end thereof to V-door 2, and a lower end thereof slidably disposed on main support structure 1, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com