One-piece non-contaminating milk or food container seal and seal removal system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

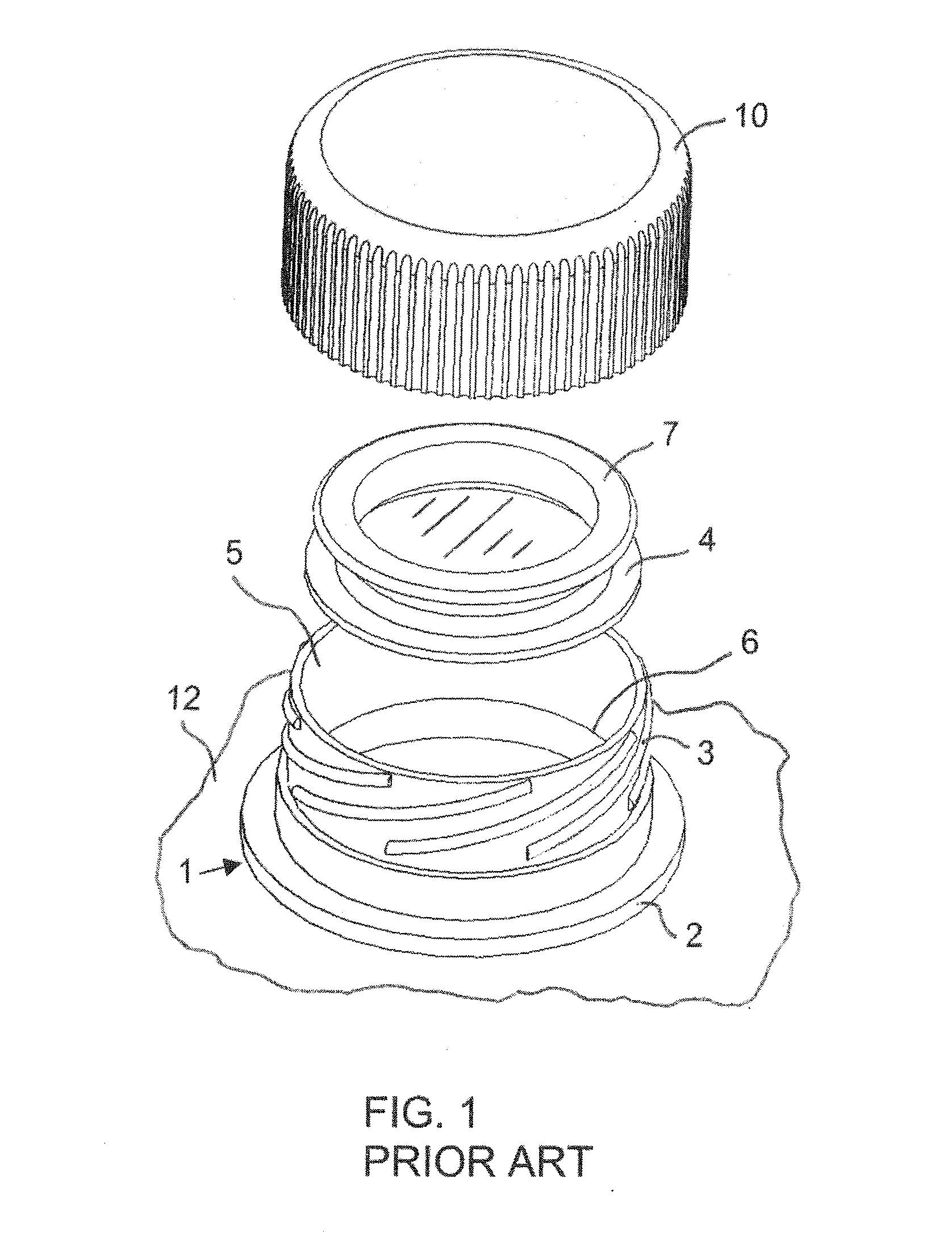

[0044]Referring now to the figures of the drawings in detail and first, particularly, to FIG. 1 thereof, there is seen a conventional entrance channel or pouring spout 1, which is attached at a bottom rim 2 thereof to an opening at the top of a milk or food container 12. A cap 10 has a non-illustrated internal thread which is to be screwed onto an external thread 3 of the channel or pouring spout 1. A prior art milk or food container seal and seal removal system includes a disk-shaped seal 4 having an outer periphery which is connected to an inner surface 5 of the channel or pouring spout 1 at a level 6. More specifically, the seal 4 is fused or cast onto the lower one-quarter of the channel or pouring spout 1. An extraction ring 7 is connected to the seal 4. The ring 7 is hooked by the finger for tearing and extracting the seal 4 from the channel or pouring spout 1, thus breaking the sterile seal of the container.

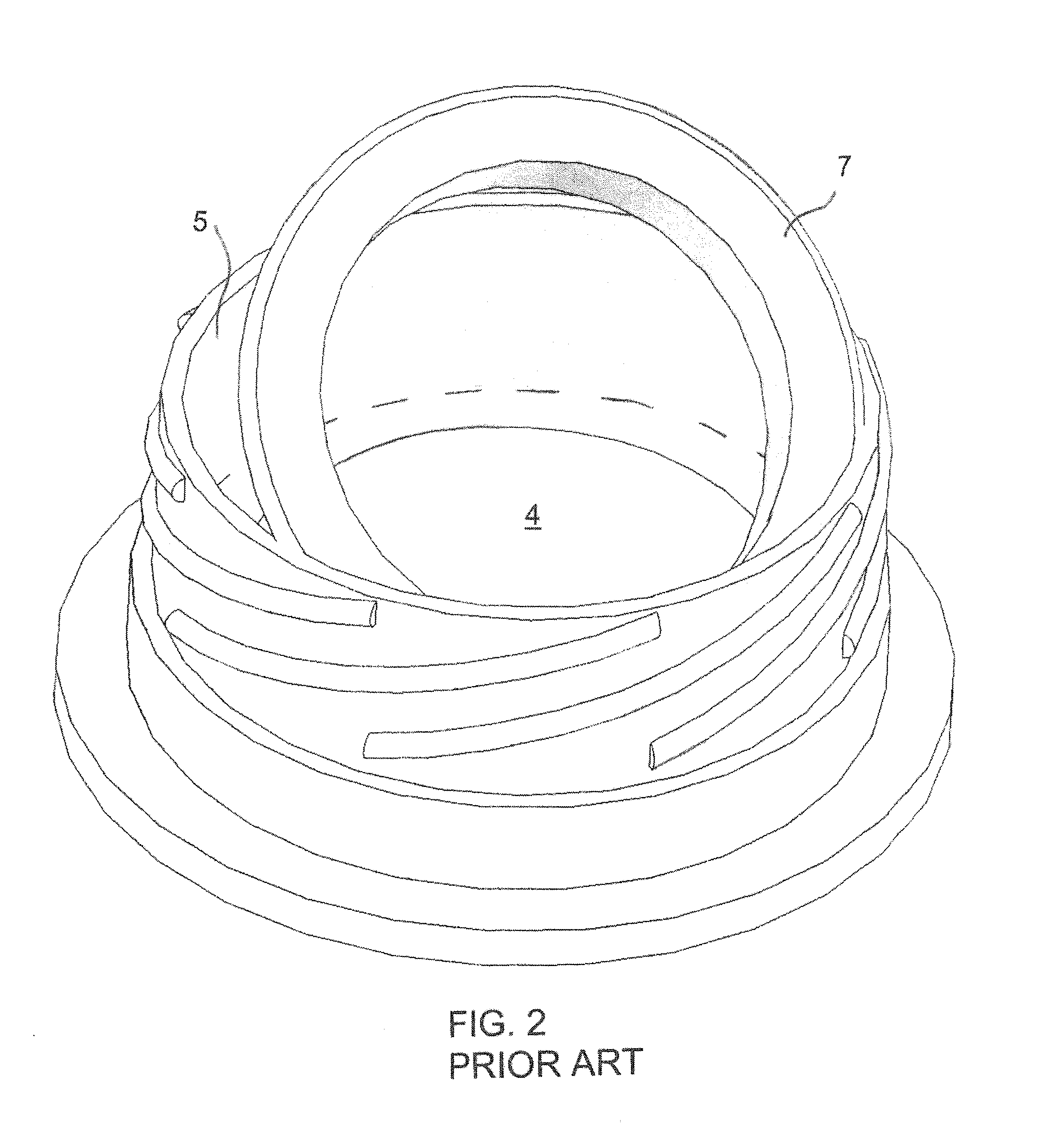

[0045]FIG. 2 shows the seal 4, the ring 7 and the channel or pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com