Packing unit, shipping unit and a method of manufacturing a packing unit

a packing unit and shipping unit technology, applied in the field of packaging units, shipping units and a manufacturing method of packing units, can solve the problems of packaging not having the same rigid quality, packaging wear, and collapsible packages cannot be stacked one over another, so as to facilitate handling and transportation, reduce lifting or other handling operations, and minimize the effect of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]The invention will now be described in more detail and specific preferred embodiments, and variations of the same, will be shown. The discussions are intended to be clarifying and explanatory and are not to be regarded as limiting the scope of the invention. The figures referred to are schematical illustrations and are not necessarily drawn to scale.

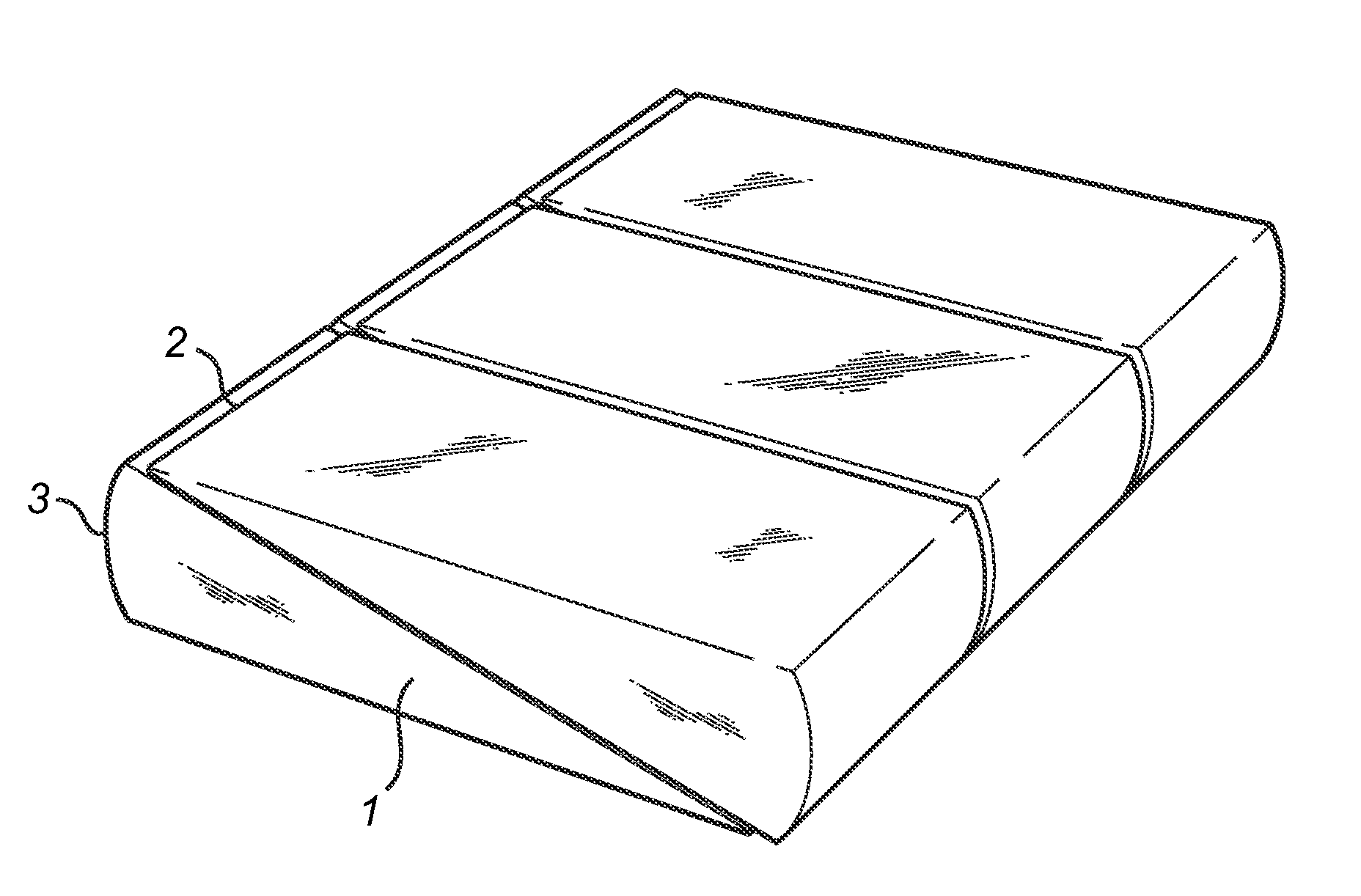

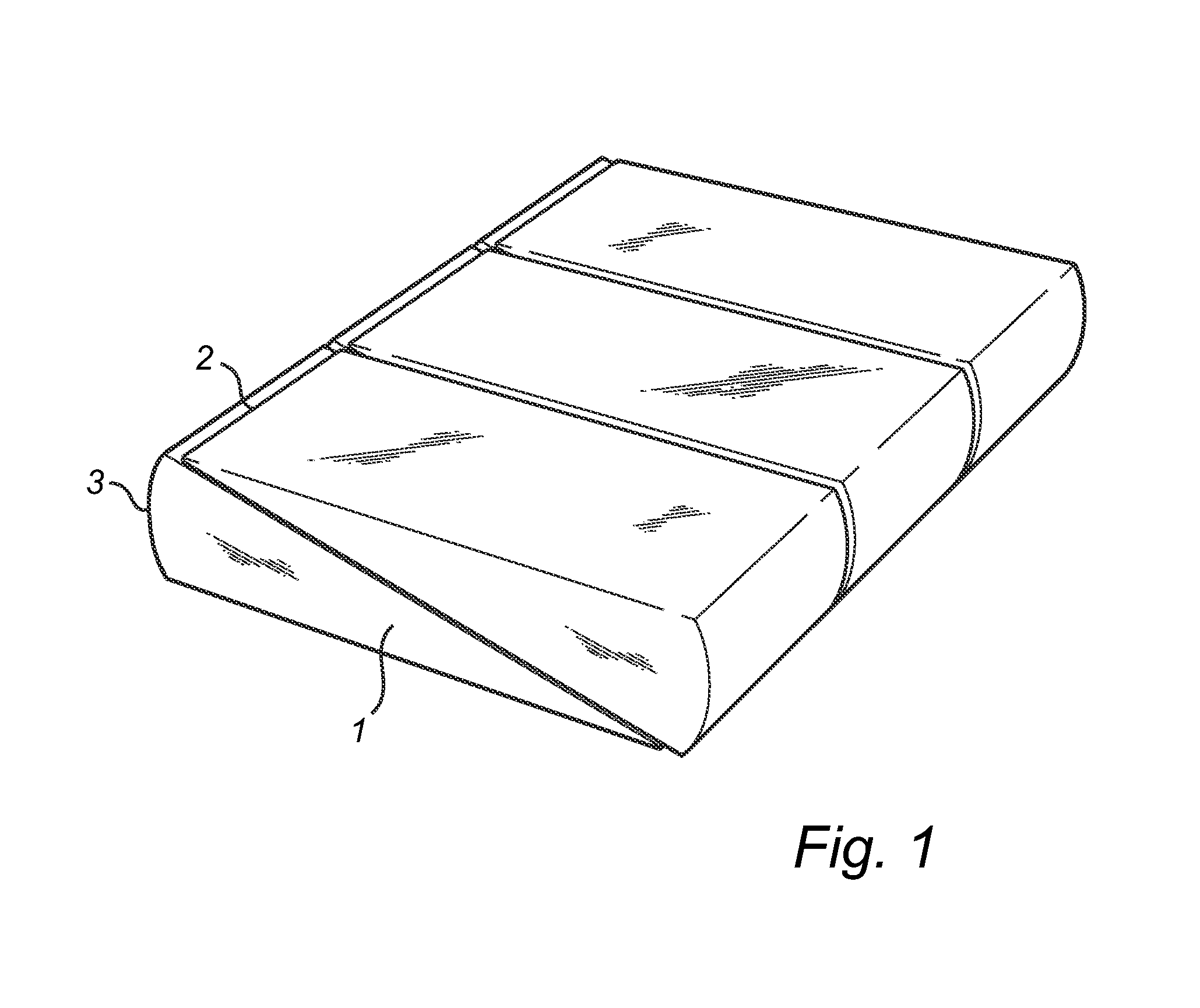

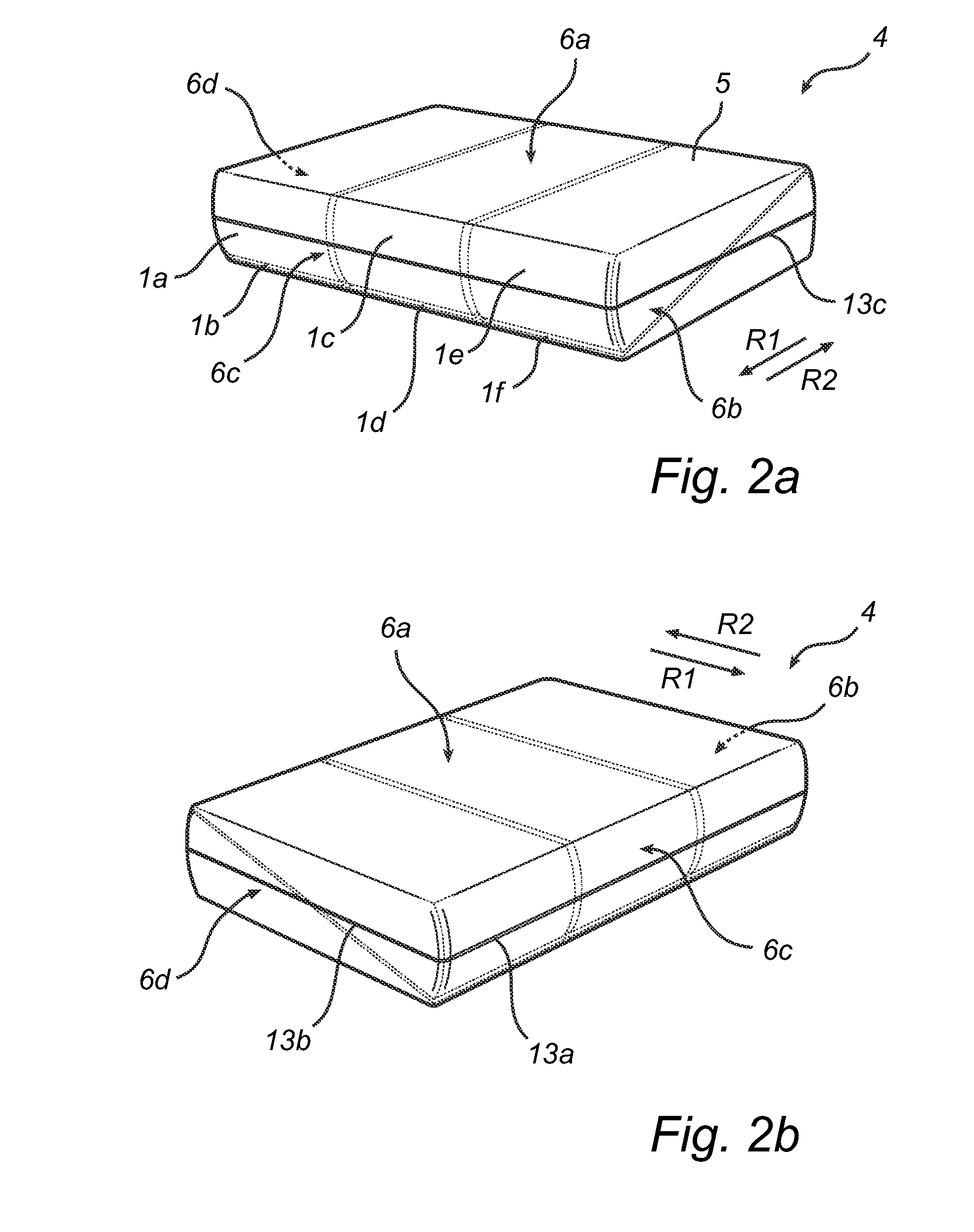

[0059]With reference to FIG. 1, packages 1 will now be discussed, the packages having an alternating orientation in a first direction and a second direction opposite to the first direction and the packages of an individual layer having a uniform orientation in the first or the second direction, according to the invention. In FIG. 1 six packages 1 are illustrated. The packages 1 have in the upright position an upwardly tapering shape, with a narrower end 2 and a wider end 3. It will be appreciated that the packages are schematically illustrated. The packing unit 1 is so arranged that each package 1 has a side wall facing a bottom of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com