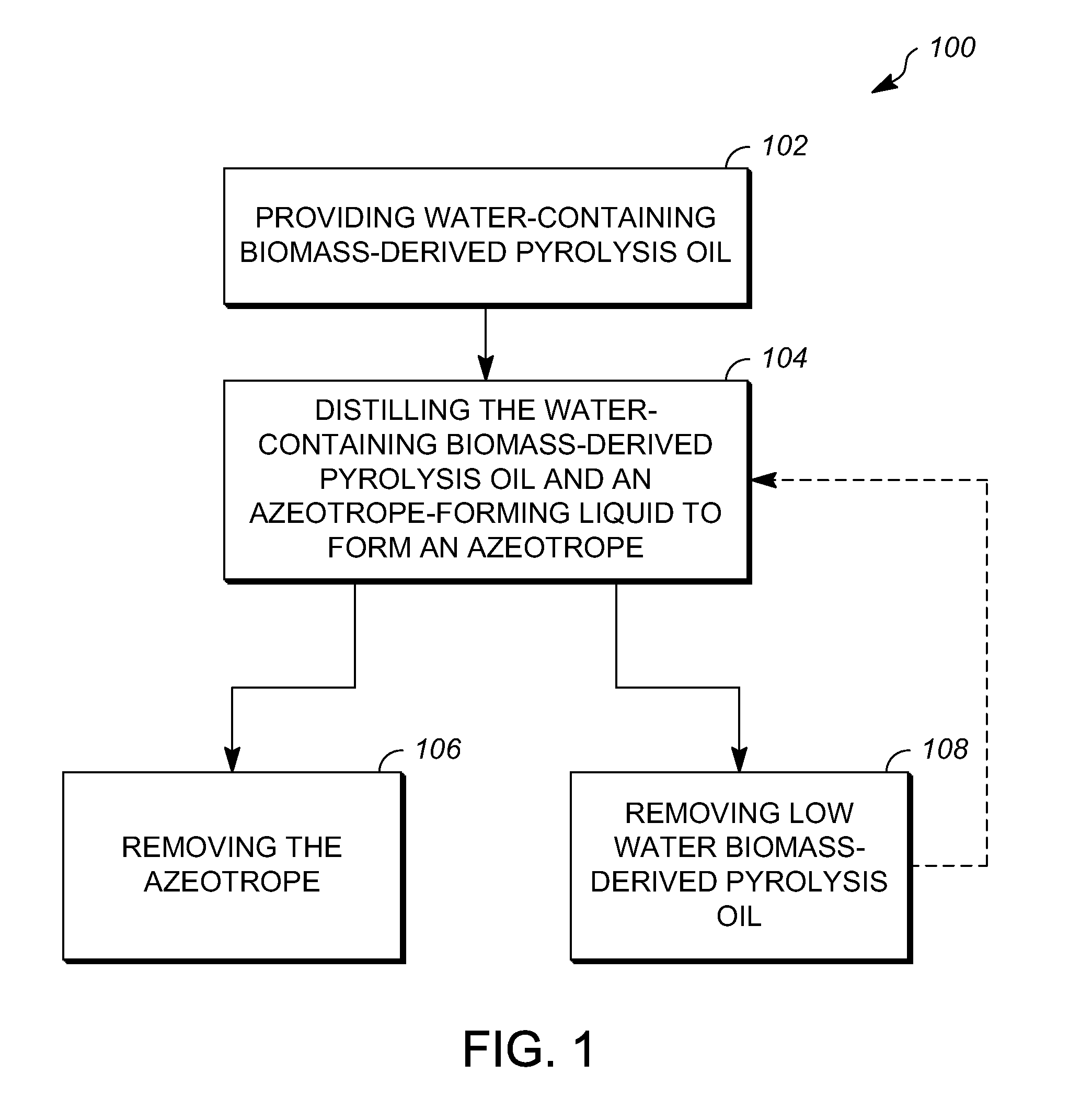

Low water biomass-derived pyrolysis oil and processes for preparing the same

a biomass-derived pyrolysis oil and low water technology, applied in the petroleum industry, azeotropic distillation, liquid carbonaceous fuels, etc., can solve the problems of increasing the storage instability of oil and the inability to distill derived pyrolysis oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

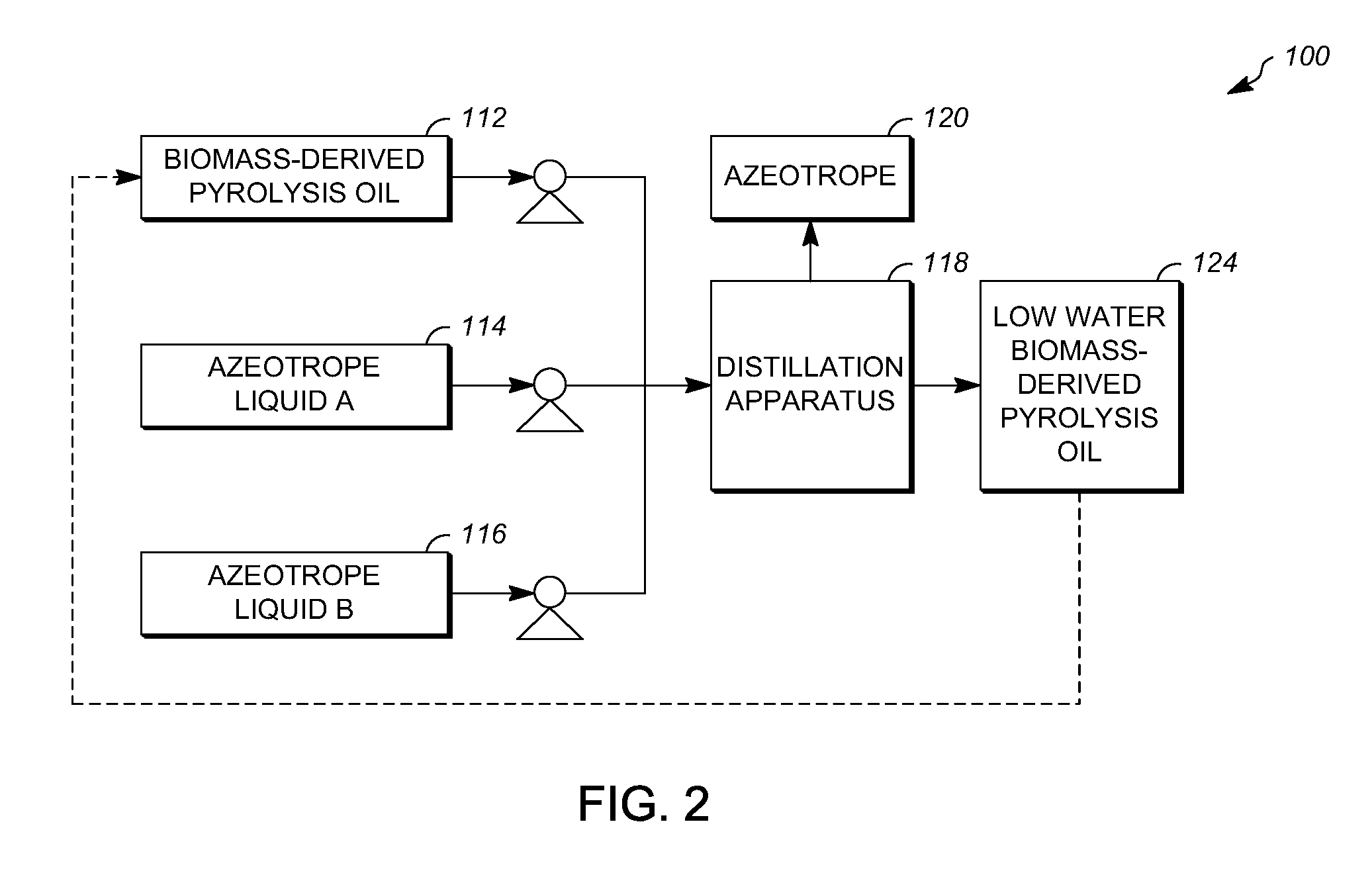

Method used

Image

Examples

example

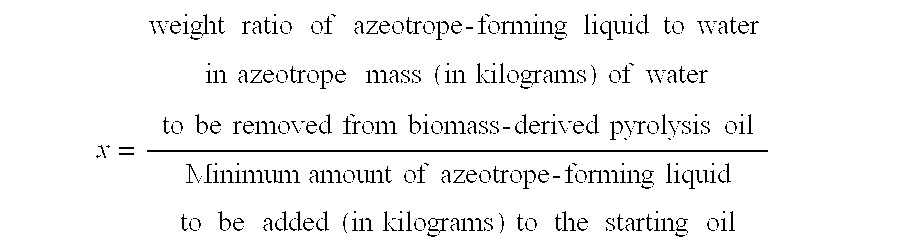

[0030]A mixture of biomass-derived pyrolysis oil (123 g, starting water content about 33 wt %), toluene (160 g) and ethanol (246 g) was placed in a rotary evaporator and heated to 90° C. Volatiles were collected and both overhead vapors (348 g) and distillation apparatus remnants (185 g) (i.e., low water biomass-derived pyrolysis oil) were characterized. The distillate composition (excluding water) was >99+% toluene and ethanol (as determined by gas chromatography) with little or no biomass-derived pyrolysis oil mass loss to overhead vapors. 96% of the toluene and 63% of ethanol was recovered in the distillate. The resultant bottoms product (i.e., distillation apparatus remnants) was low water biomass-derived pyrolysis oil having about 6.7 wt % water. Thus, 185 g of low water biomass-derived pyrolysis oil with 6.7 wt % water=12.4 g of water. The starting biomass-derived pyrolysis oil (132 g, 33% water) had 43.6 g water. Thus, 43.6-12.4 / 43.6=71.6% of the water was removed from the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| azeotrope | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com