Dfp w1 wall hood

a wall hood and dfp technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of mold growth on and in the walls, significant clogging of exhaust ducts, and lint being a common cause of allergies, so as to achieve maximum safety and efficiency in dryer operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

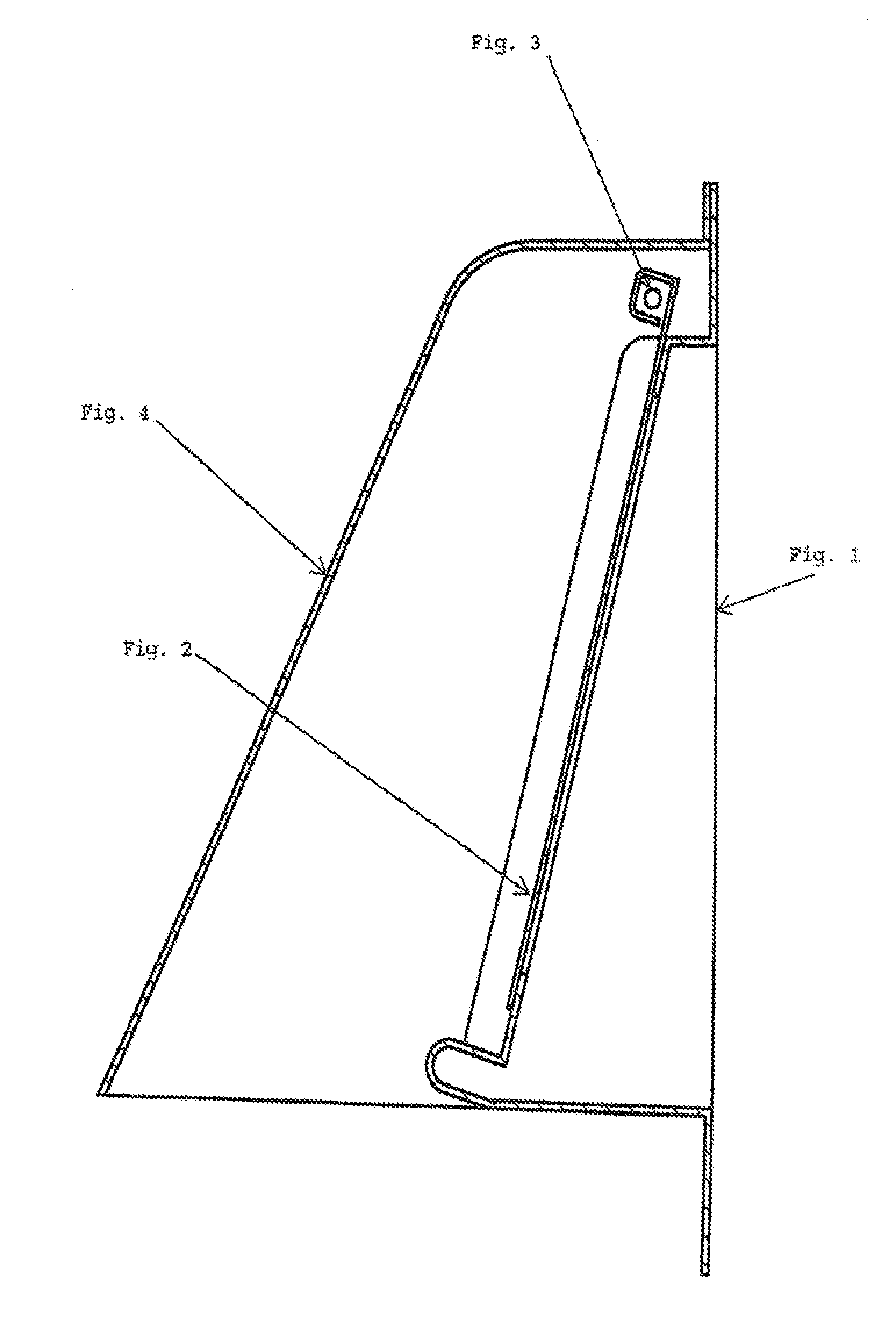

[0048]The Mechanical Building Code, section 504.1 states “Clothes dryers shall be exhausted in accordance with the manufacturer's instructions. Dryer exhaust systems shall be independent of all other systems and shall convey the moisture and any products of combustion to the outside of the building.” Manufacturers' instructions regarding wall vent hoods include:[0049]1. Unobstructed outflow;[0050]2. A damper flap that opens during dryer operation and closes when the dryer is idle;[0051]3. A barrier to wildlife;[0052]4. An opening equal to the size of the exhaust duct. This is mandated to be four inches in diameter by The Mechanical Building Code, section 504.6.

[0053]In accordance with the invention, when the dryer exhaust duct terminates on a vertical exterior wall, the invention provides a particularly effective method of preventing air, weather elements and wildlife from entering the dryer duct. It still allows for unrestricted airflow and easy access to the duct for required clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com