Axle assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Before turning to the figures, which illustrate the exemplary embodiments in detail, it should be understood that the present application is not limited to the details or methodology set forth in the description or illustrated in the figures. It should also be understood that the terminology is for the purpose of description only and should not be regarded as limiting.

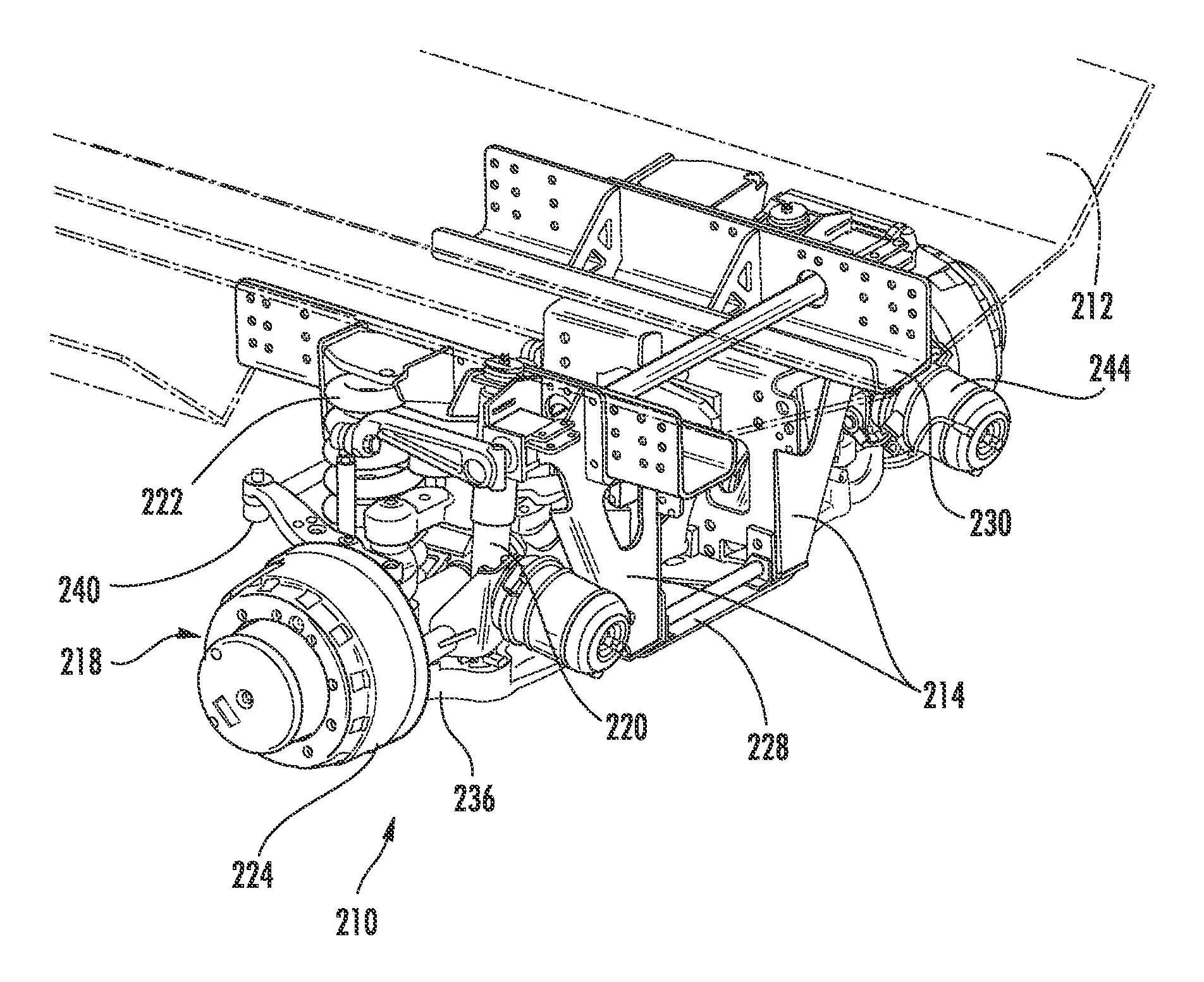

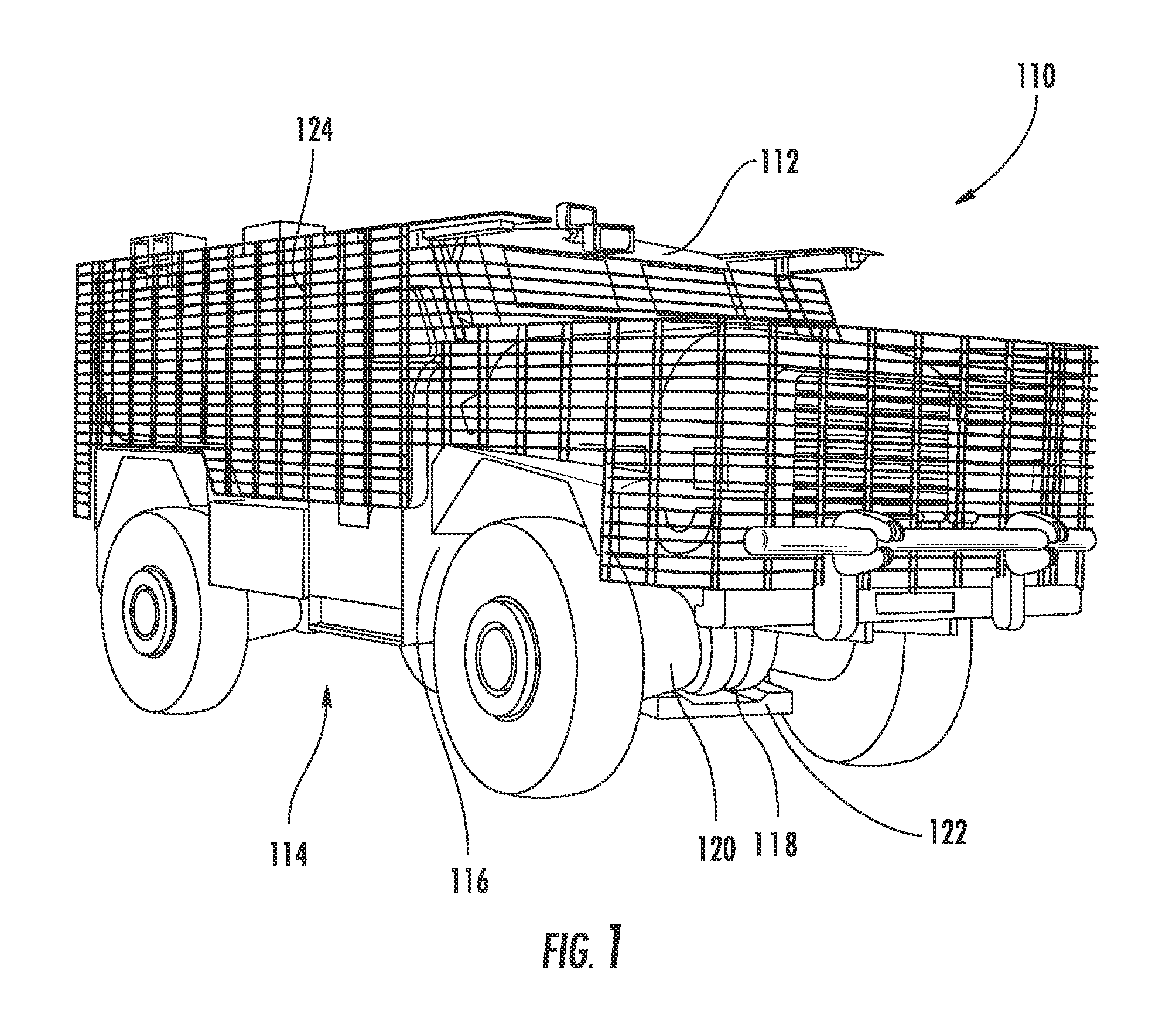

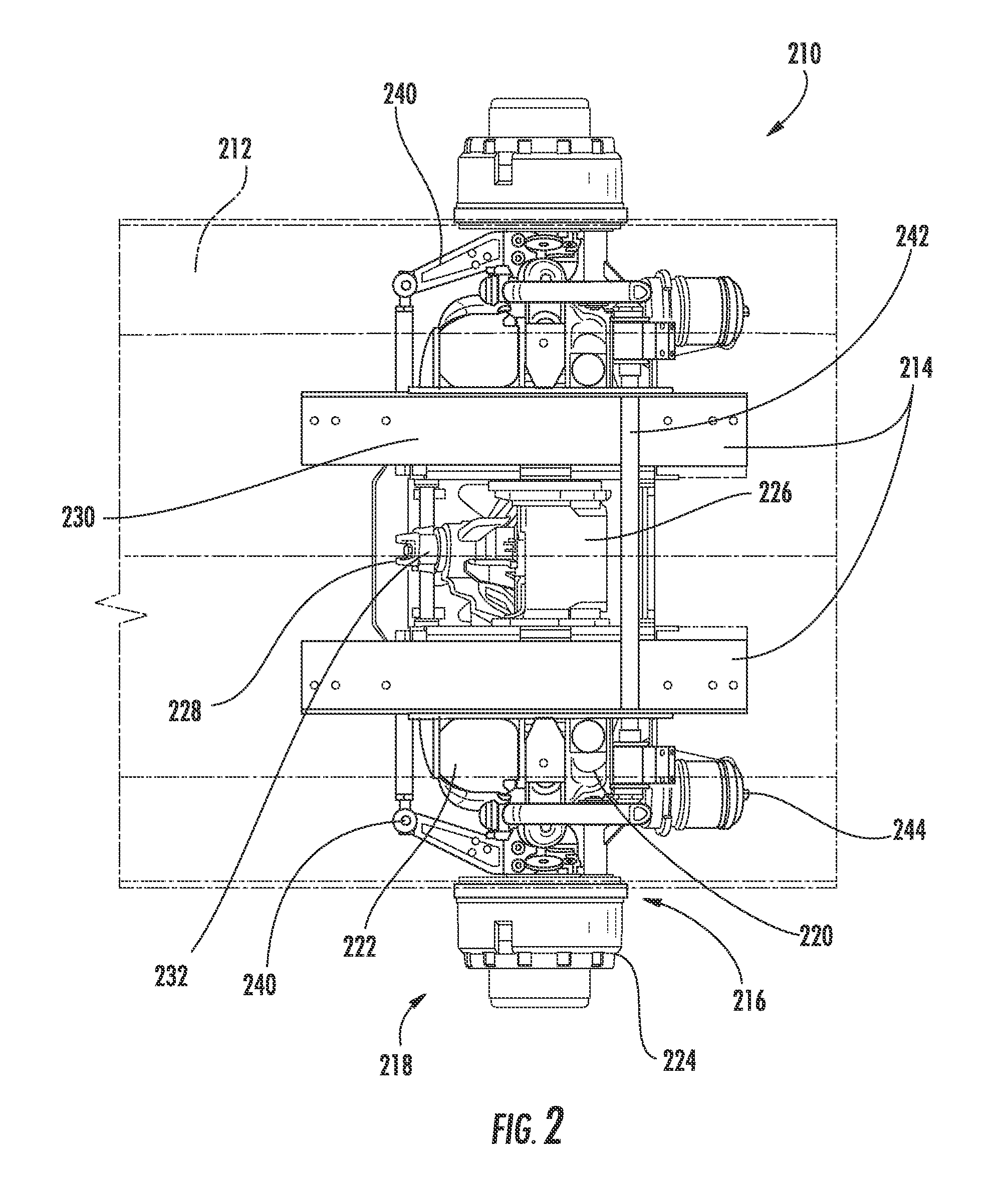

Referring to FIG. 1, a heavy vehicle 110 includes a cabin 112 (e.g., cab, housing) having an undercarriage 114 therebelow. The undercarriage includes an underside of hull 116 (see, e.g., hull 212 as shown in FIGS. 2-4), such as a blast resistant hull, which is supported by an axle assembly 118. The vehicle further includes a prime mover (e.g., diesel engine, gasoline engine, electric motor, etc.) powering a drive train (e.g., driveline). The drive train includes a transmission, a driveshaft (see, e.g., driveshaft 320 as shown in FIG. 5) rotatably coupled to a differential (see, e.g., differential 414 as shown in FIGS. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com