Gas burner for ovens or grills

a burner and gas technology, applied in the field of gas burners, can solve the problems of affecting the operation of the burner, and requiring multiple attempts by users, and achieve the effect of facilitating maintenance replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

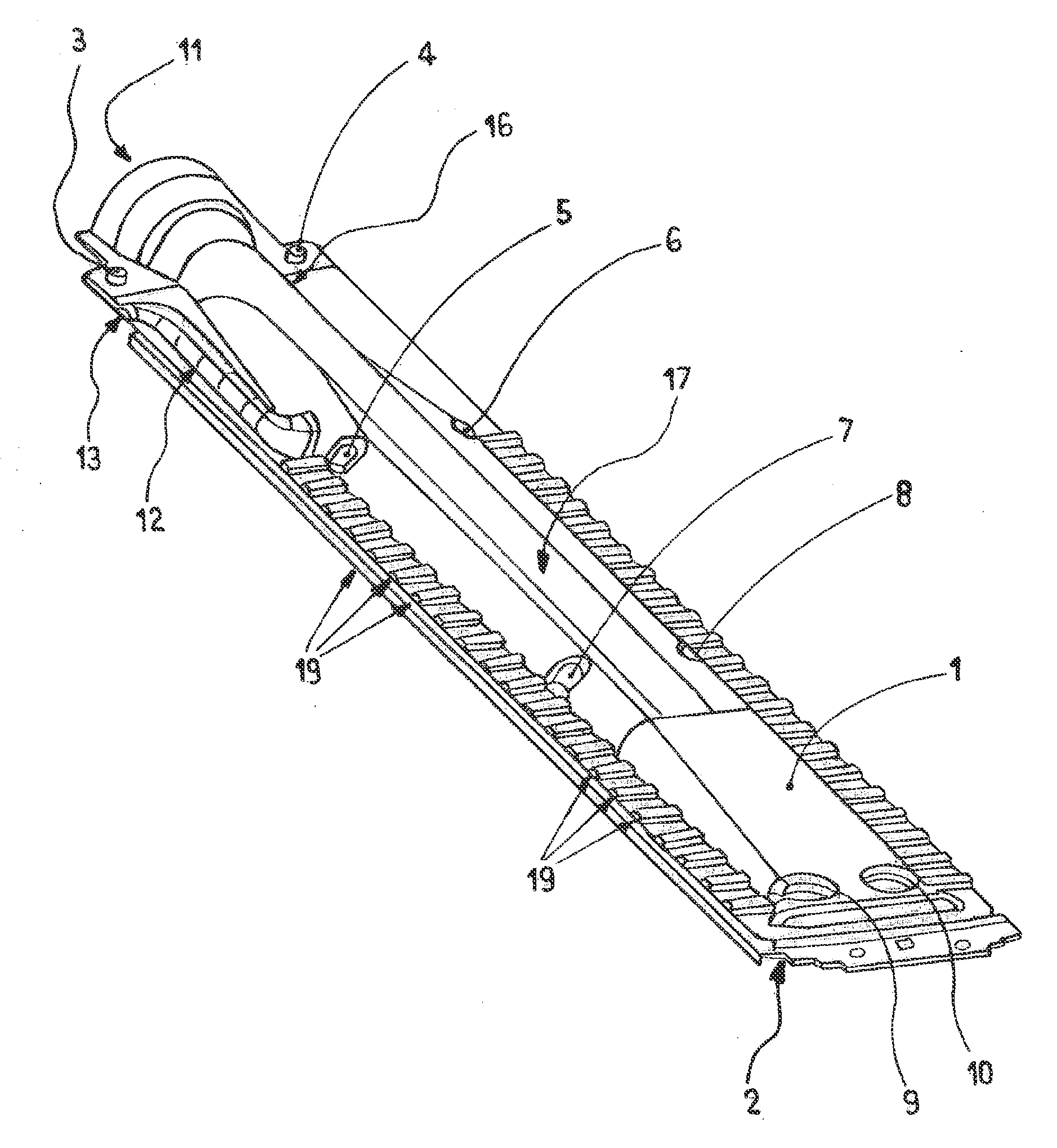

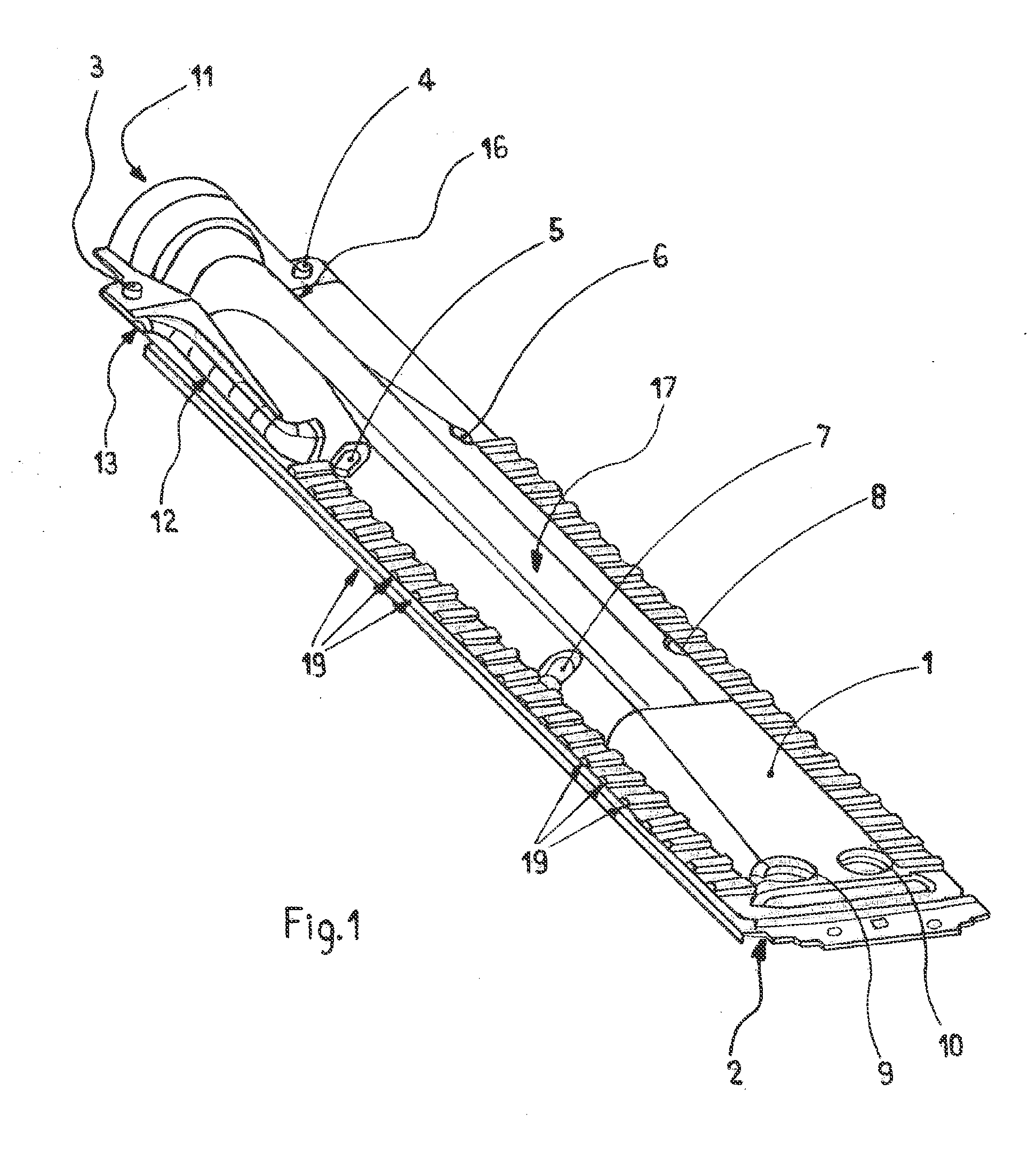

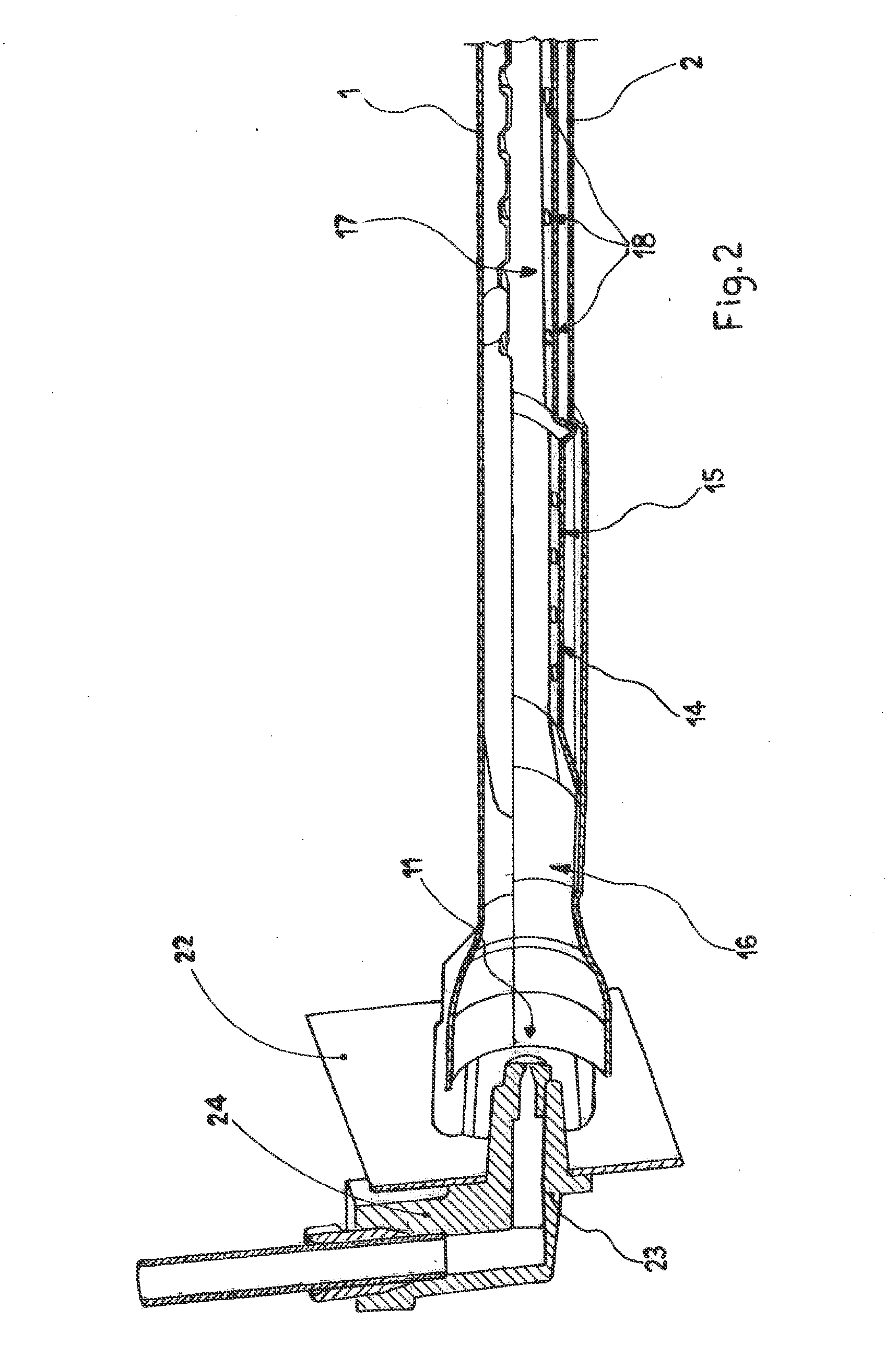

[0031]Firstly referring to FIG. 1, the gas burner object of the present invention, in its preferred embodiment herein explained, comprises an upper metallic semi-shell 1, a lower metallic semi-shell 2, and preferably an intermediate pierced plate 14, all preferably shaped by moulding, such that to define in their inside, once coupled, a Venturi tube 16 for mixing the fuel gas with air (primary air) drawn from the outside of the burner, and at least one elongated chamber 17, coaxial to the Venturi tube 16, for distributing the fuel mixture of gas-primary air to a plurality of flame openings 19, directly realized along the side walls of the elongated chamber 17, or anyway fluidically connected to such a distribution chamber 17.

[0032]The two semi-shells 1, 2 might be mutually coupled, preferably, as will be mentioned, with the interposition of a pierced plate 14, by known clamping elements 3, 4, 5, 6, 7, 8, 9, 10, for example of the screw and nut screw type, situated in various places ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com