Simulated Masonry Wall Panel with Improved Seam Integration

a technology of seam integration and simulated masonry, applied in the field of wall coverings, can solve the problems of affecting the precision of the panels, affecting the accuracy of the panels, and difficulty in concealing the panel-to-panel identity of the panels formed with simulated hand laid stone or brick patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

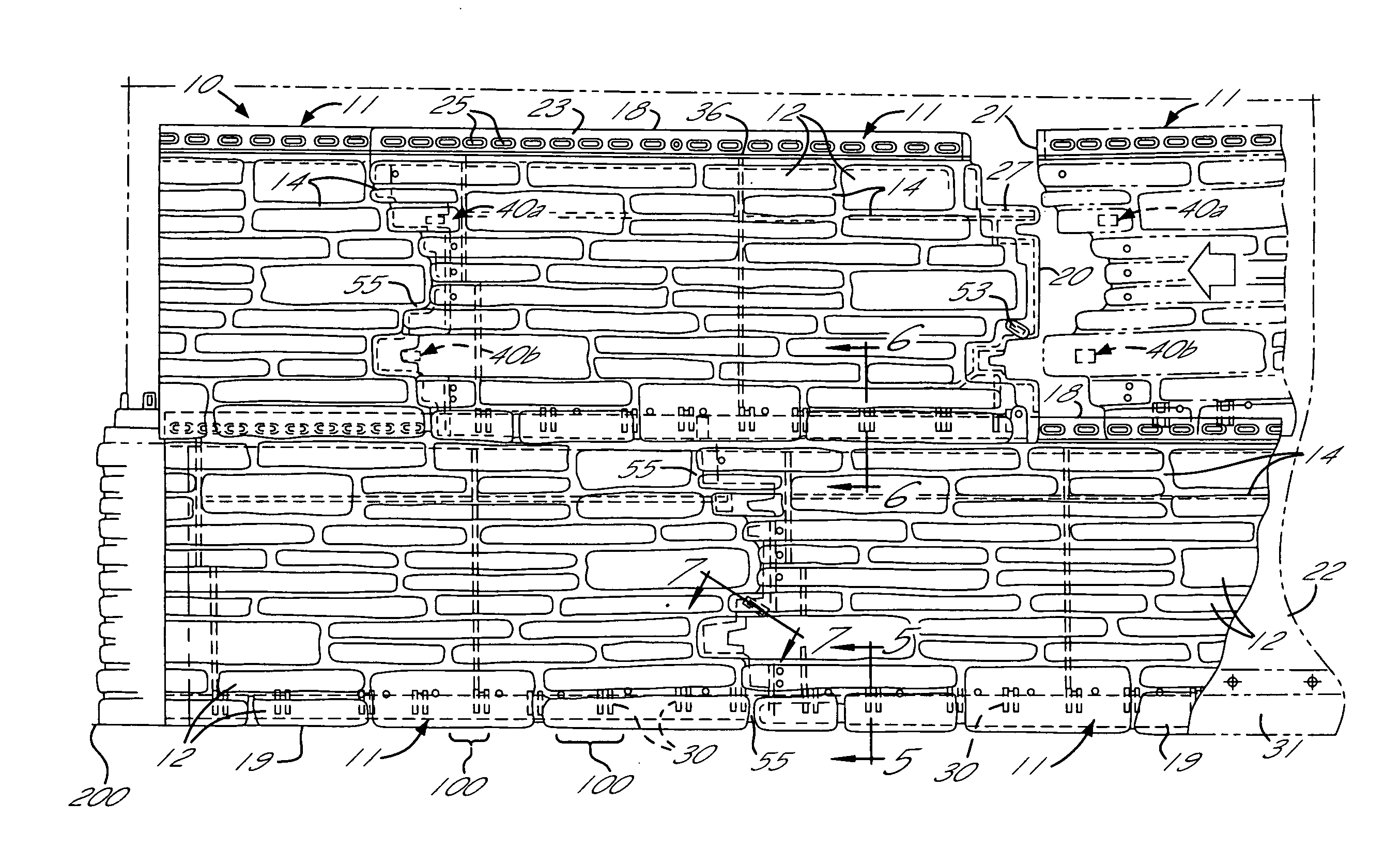

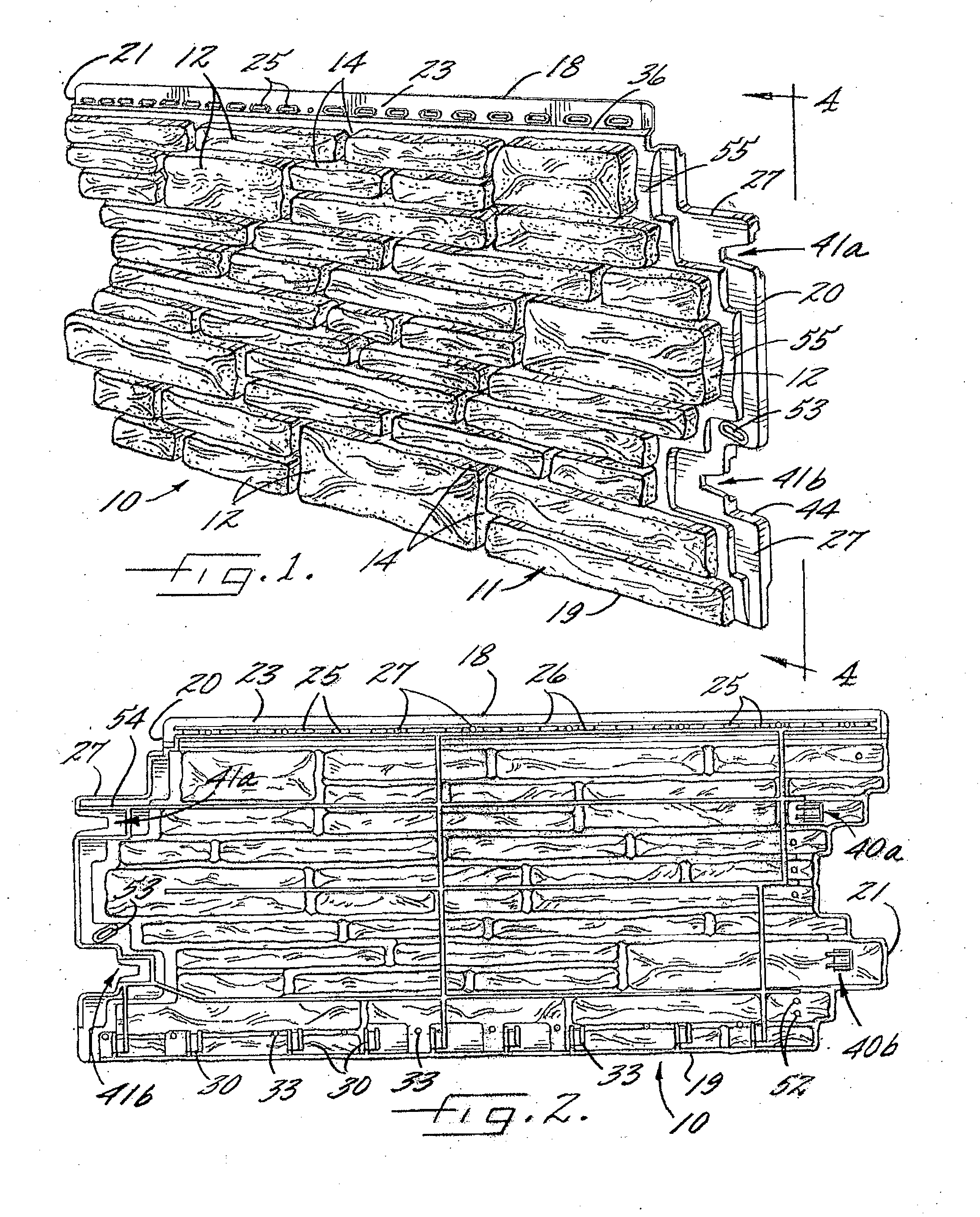

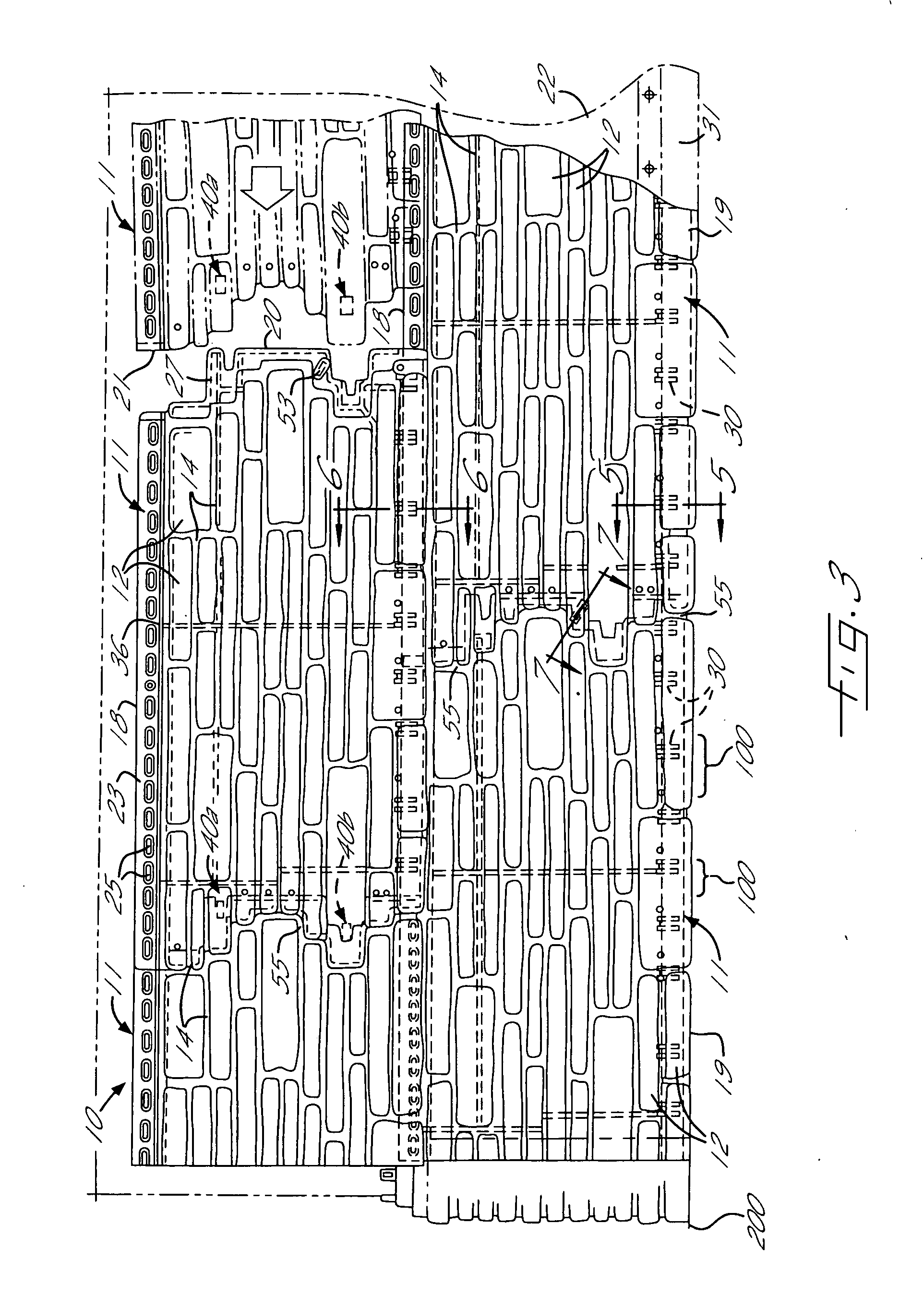

[0036]Referring now more particularly to the drawings, there is shown an illustrative wall covering 10 comprising a plurality of panels 11 in accordance with the invention. The panels 11, which preferably are molded of thermoplastic material, are formed with a simulated stone and mortar design, typical of hand-laid stone masonry. The simulated stone 12 in this case is generally disposed in a plurality of parallel horizontal rows with the stones 12 being isolated from each other by simulated lines of mortar 14. The stones 12 protrude outwardly of the mortar lines 14, typical of hand-laid stone, and some of the simulated stones 12 in this instance have a width (i.e. a vertical dimension as viewed in FIG. 1), greater than other of the stones in the row. The simulated stone 12 has irregular outer surfaces consistent with natural stone, and the mortar lines 14 also have a waving, or undulating, non-planar naturally appearing outer surface configuration. While the invention has particular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com