Closure with built-in storing compartment

a technology of built-in storage compartments and closures, which is applied in the direction of caps, packaged goods types, liquid handling, etc., can solve the problems of 3 to 5 multiplied by the overall cost of the package, all of the above described closures fail to provide an economic and easy-to-use solution, and are clearly not acceptabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

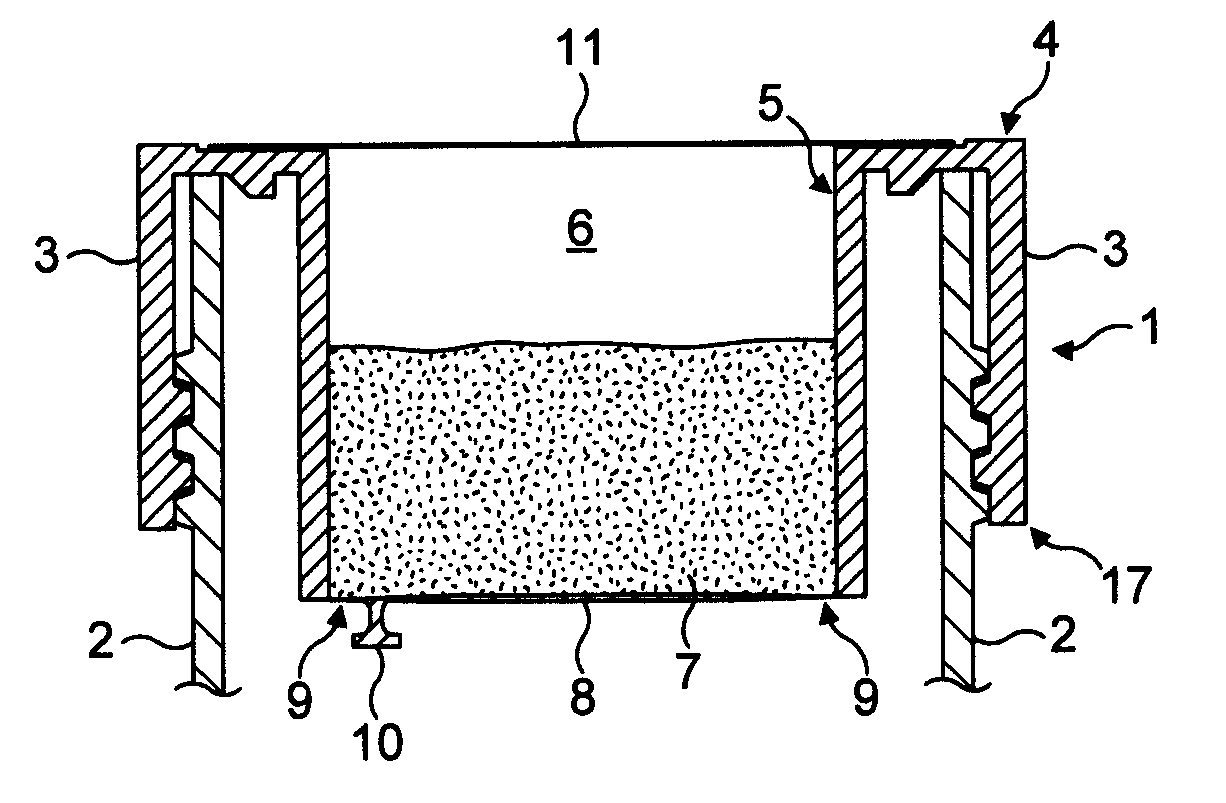

first embodiment

[0047]In this first embodiment, the closure 1 is transported to a closing machine of the factory, where it is then screwed onto the neck of a bottle that has previously been filled with a liquid, for instance a liquid yogurt. The bottle is made out of a material which is barrier to oxygen. The closure compartment 6 is then filled with a second product 7 in powder form—eg. a mix of probiotics, vitamins, and minerals—through the top opening of the internal skirt 5, under aseptic conditions, after which filling, an aluminium membrane 11 is sealed onto the top 4 of the closure 1. In that way, the skirt 5 closed with the aluminium membrane 11 defines a closed compartment 6 that is filled with the second product 7.

[0048]By “aluminium membrane”, it is meant a membrane made of aluminium that further comprises a sealing layer such as eg. polyethylene (PE) or polypropylene (PP), so that the membrane can be sealed to the closure by heat sealing or ultrasonic sealing techniques for instance. Al...

third embodiment

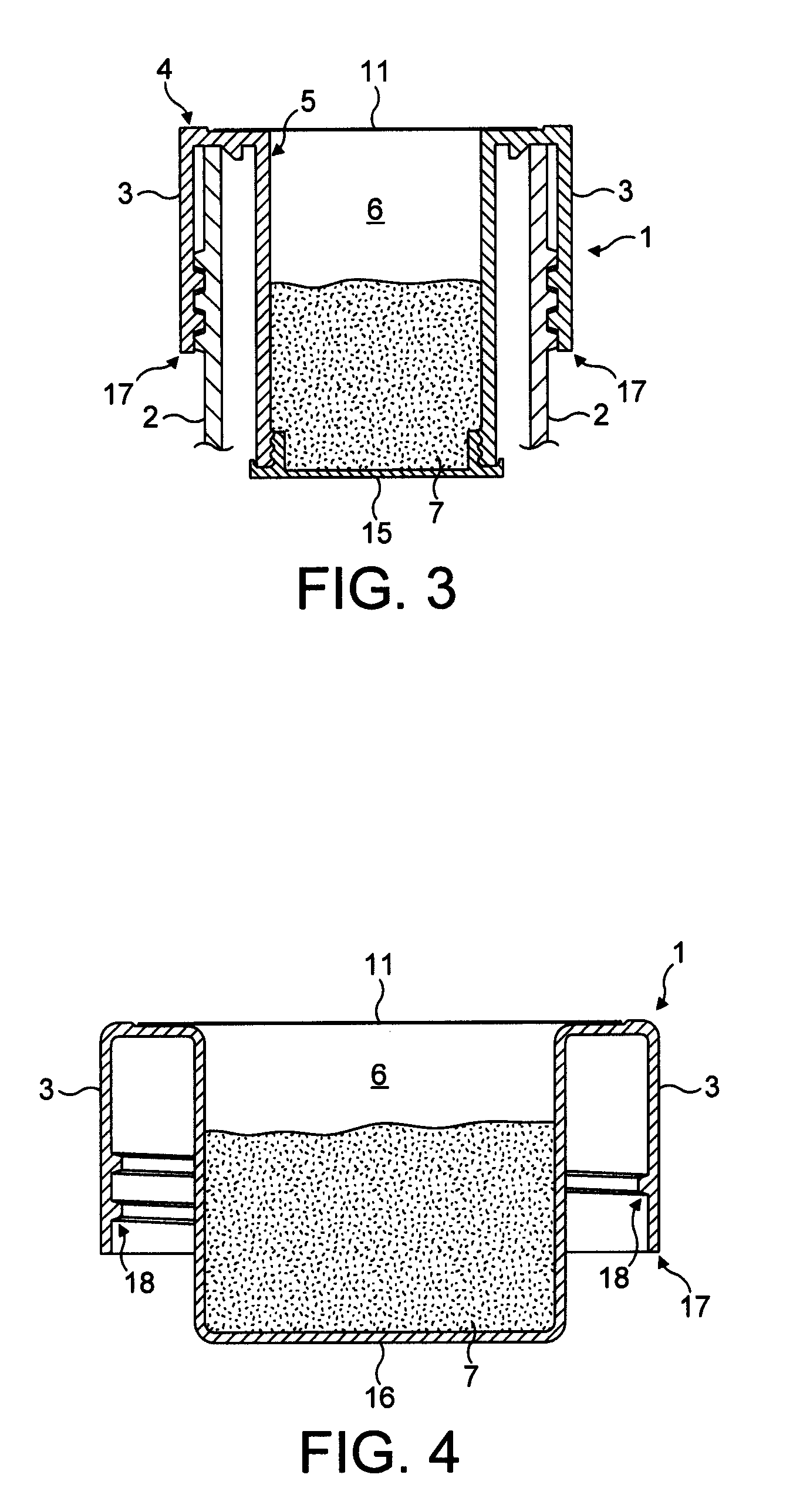

[0057]In a fourth possible embodiment of the invention illustrated in FIG. 4, the closure 1 is very similar to the closure described for the third embodiment above. However in this particular case, the bottom wall 16 of the closure internal skirt is moulded integrally with the rest of the closure.

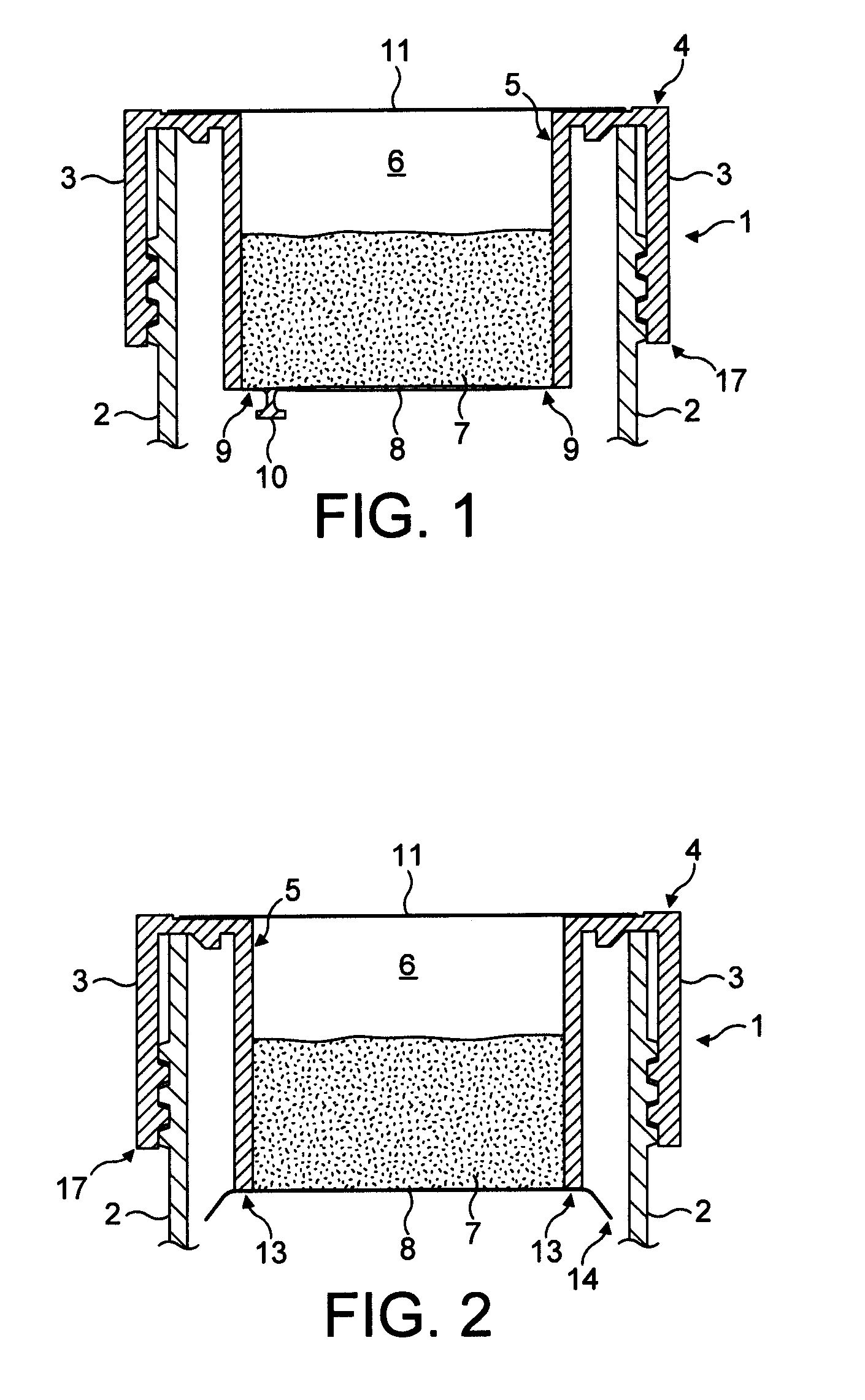

[0058]In all of the preceding embodiments of the invention described herein above, the skirt 5 preferably downwardly extends in height from the top wall 4 of the closure 1, below the level of the lower edge 17 of the closure side walls 3. This can be seen clearly, for instance on FIGS. 1 to 4. Finally, the closure 1 is preferably secured onto the neck 2 of the bottle by screwing, and to this effect, the closure side walls 3 comprise screw threads 18 disposed along the internal surface of the side walls 3 of the closure. The screw threads are means to cooperate with corresponding screw threads 19 of the container neck 2.

[0059]The present invention is further directed to a process for filling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com