Crack resistant coating and method of applying crack resistant coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

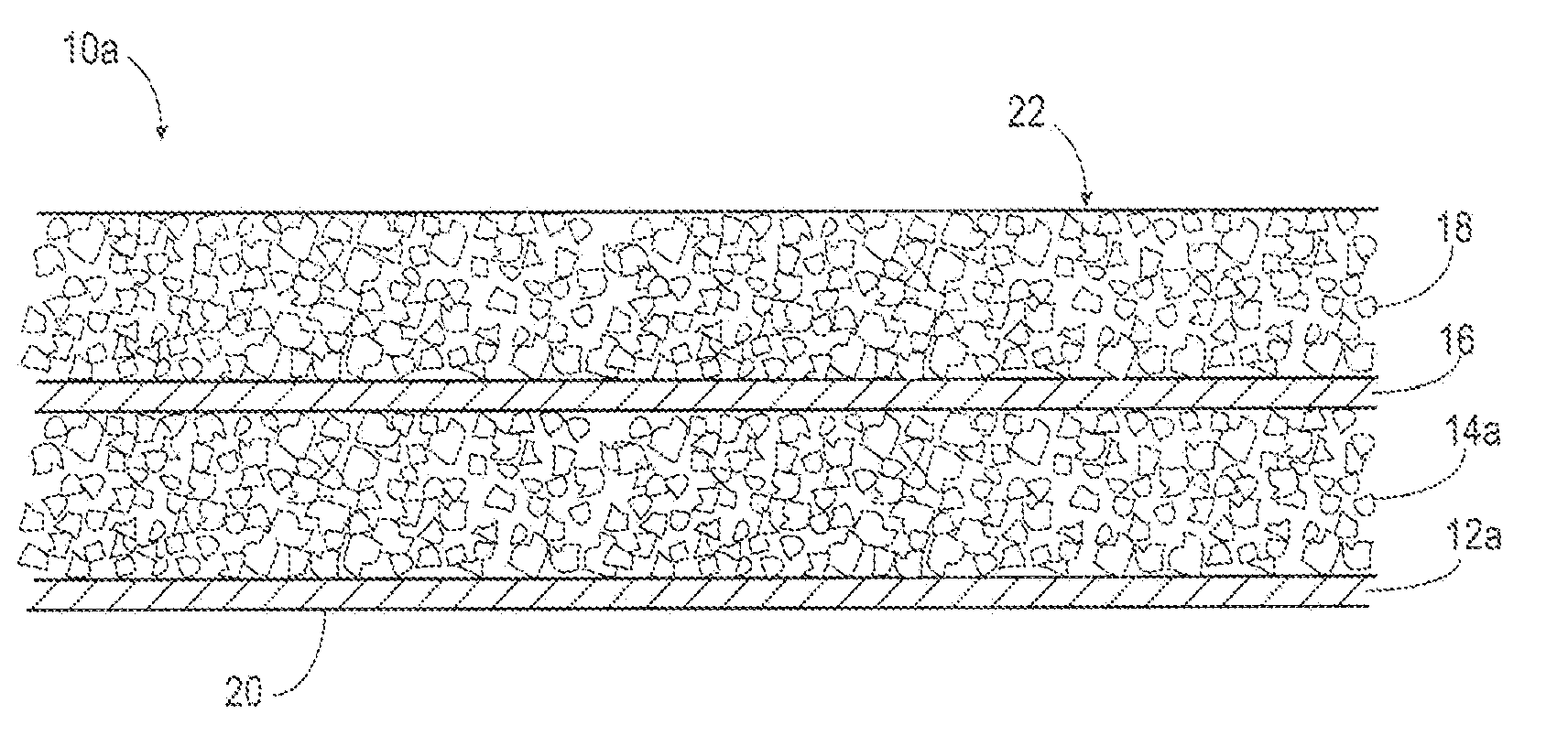

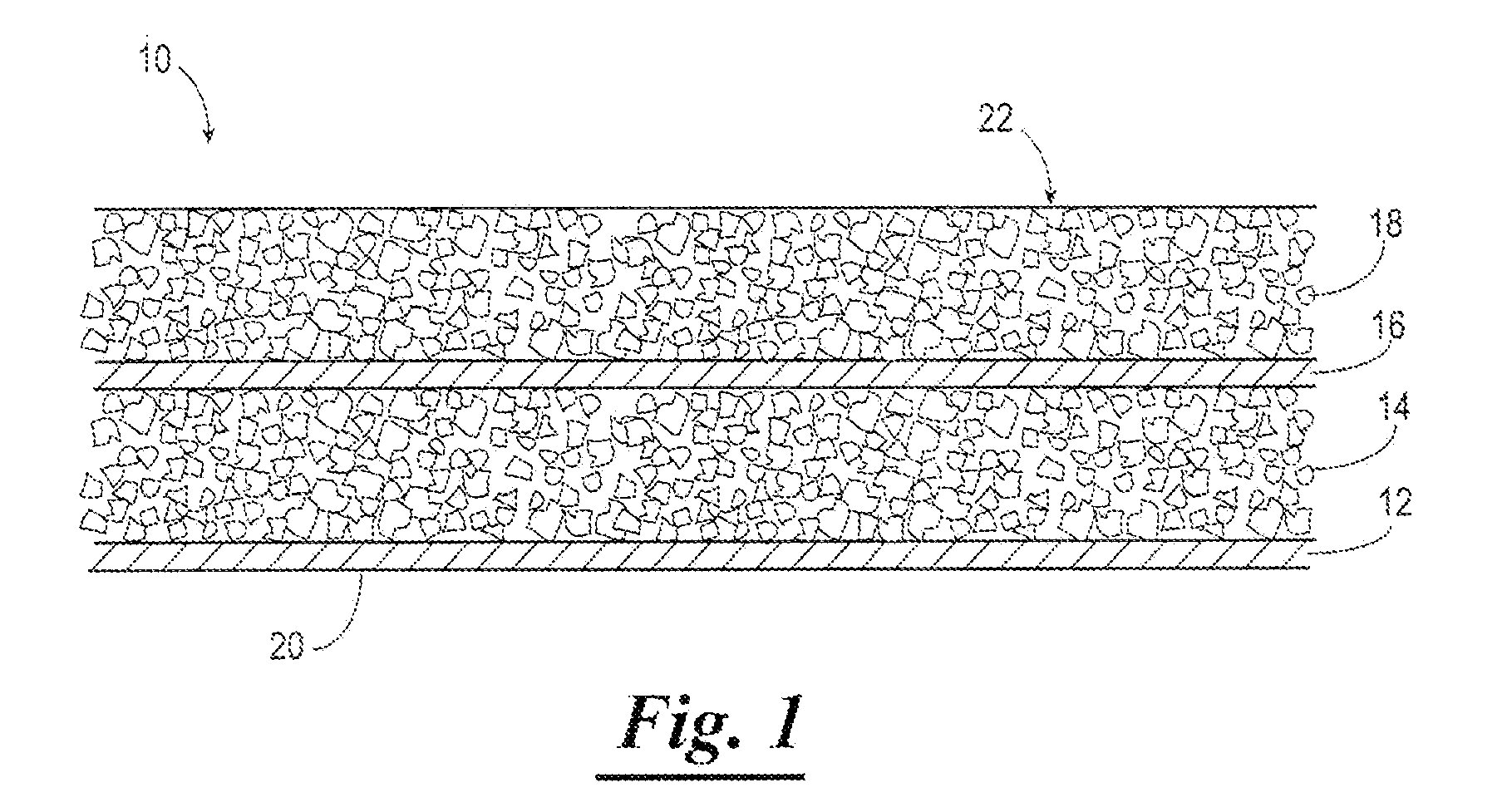

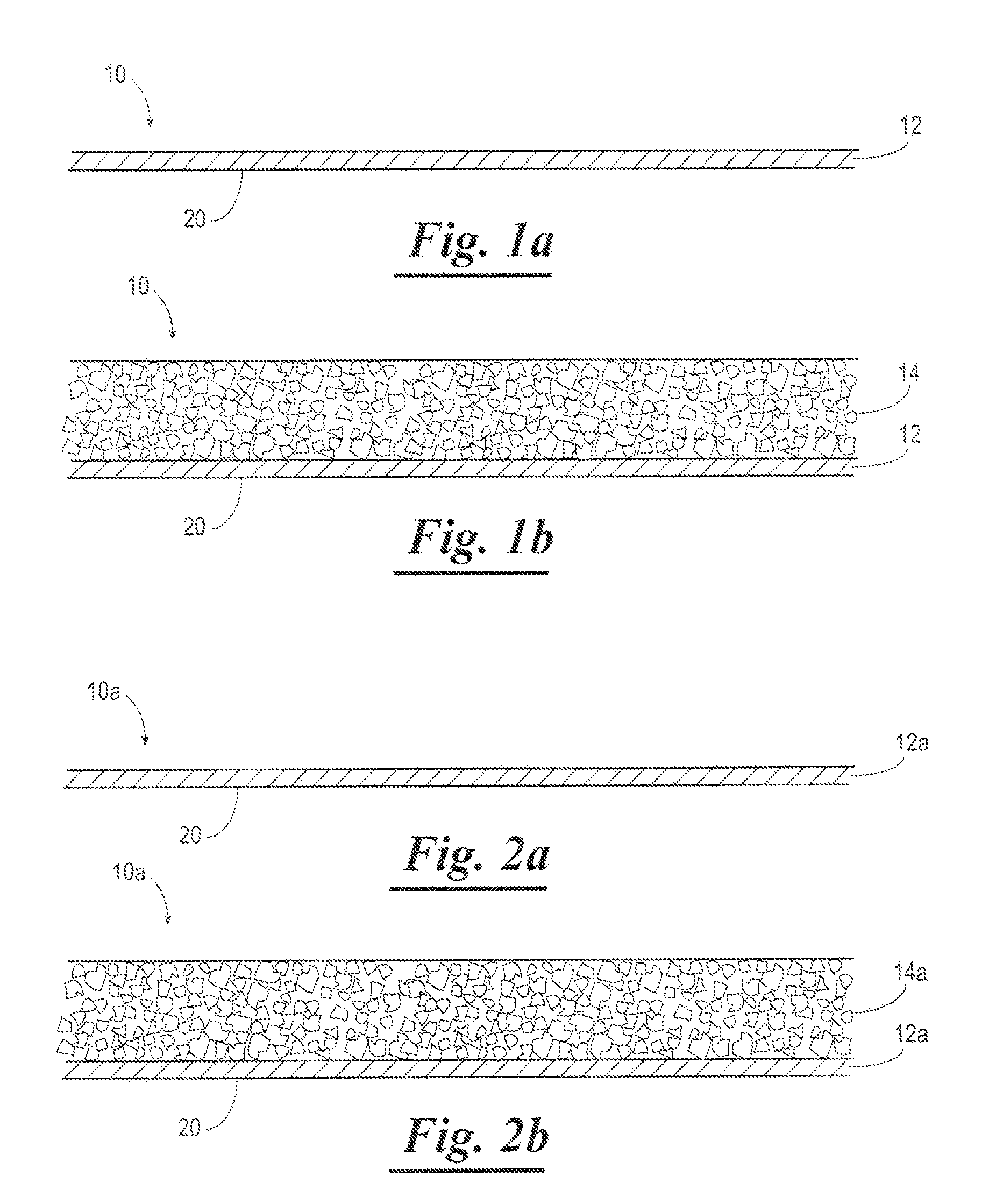

Image

Examples

example 1

[0075]A test trial was executed in Missouri on Route T about 5.6 Km West of Route 100. A dense graded (<10% air voids) aggregate mixture was produced using aggregate particles and asphalt solution. The aggregate mixture utilized 4.8% asphalt solution by weight and exhibited 5.0% air voids. All Crack Resistant Layers were applied at about 4.44 cm thick. Prior to experimentation, the road was surveyed for cracks and it exhibited an uneven crack pattern, Table #1 shows the data from the test site.

TABLE #1Field ExperimentSt Albens Road, Route T Missouri - 5.6 Km West of Rte 1005% air voids, 4.8% binder content, 4.44 cm thick thickEmulsified BindingEmulsionBonding LayerExisting CracksLayer (L / m2)ResidueL / m2per 1000 m (m)0.36132%0.1169350.67862%0.42012350.84062%0.521937

[0076]Table #2 shows the calculated results from the trials and crack count data after 9 months of service. The data shows the control section with 0% AVFA, 0.00 cm in height of Substantially Voidiess layer and a Total Bind...

example 2

[0078]A second field trail was conducted on private property with an open graded aggregate mixture. In normal application, an aggregate mixture with >10% air voids is considered open graded and has little to no resistance to cracking. The first section was produced with one binding material layer and one aggregate mixture layer. The second experimental section was produced utilizing a binding material and aggregate mixture followed by a successive application of another binding material and aggregate mixture. All binding materials were the same as well as all aggregate mixtures were identical.

TABLE #3Field Data - 18 months oldTulsa Field Trial10.0% air voids, 5.25% binder contentEmulsified BindingEmulsionBonding LayerMixtureLayer (L / m2)ResidueL / m2Depth (cm)1.08462%0.6722.222.53062%1.5693.49

[0079]Table #3 details the application data. Both experimental sections utilized high rates of binding material.

TABLE #4Calculations and ResultsTulsa Field TrialVoidlessTotal BindingFilledMaterial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com