1-axis and 2-axis solar trackers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

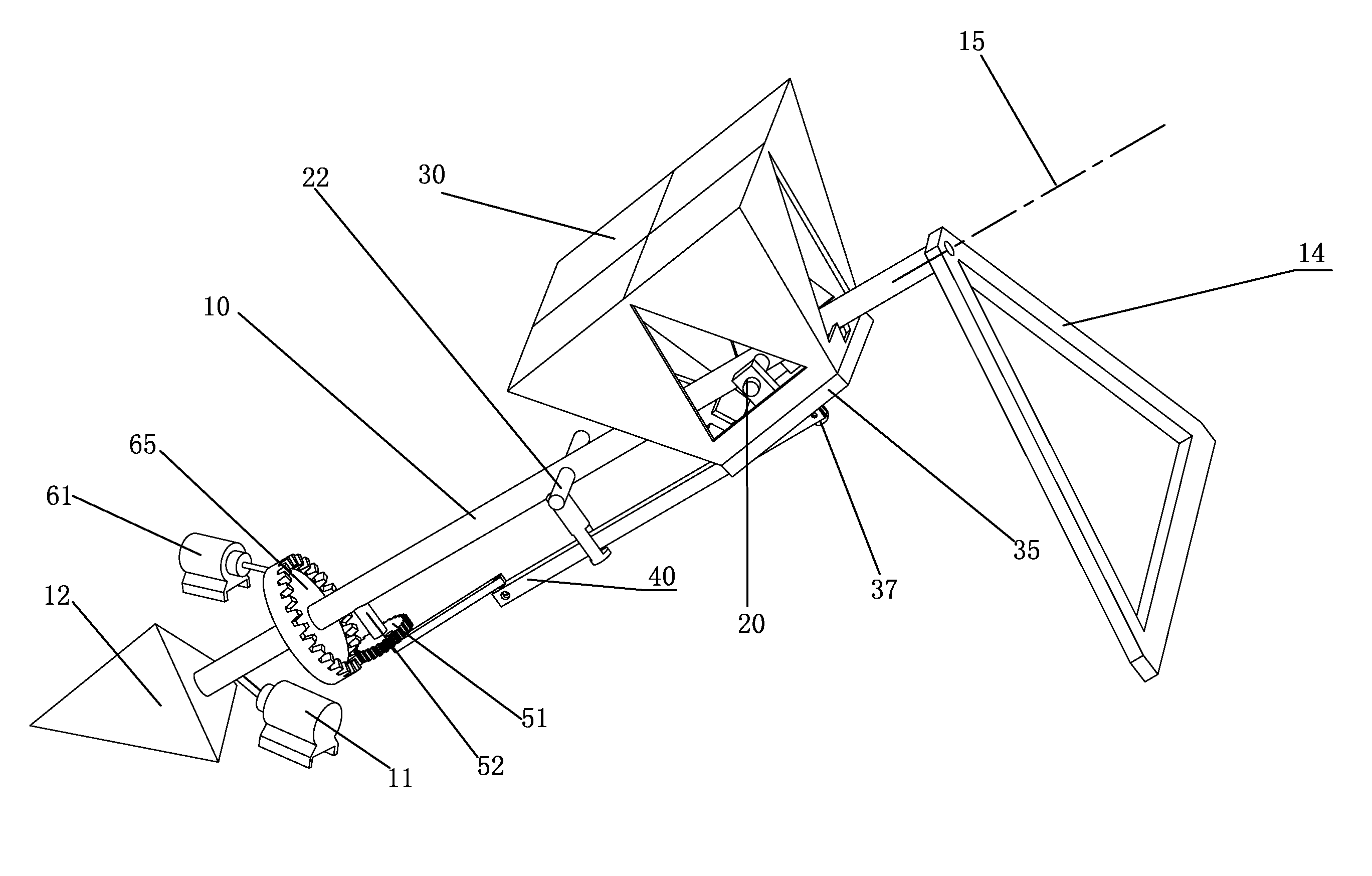

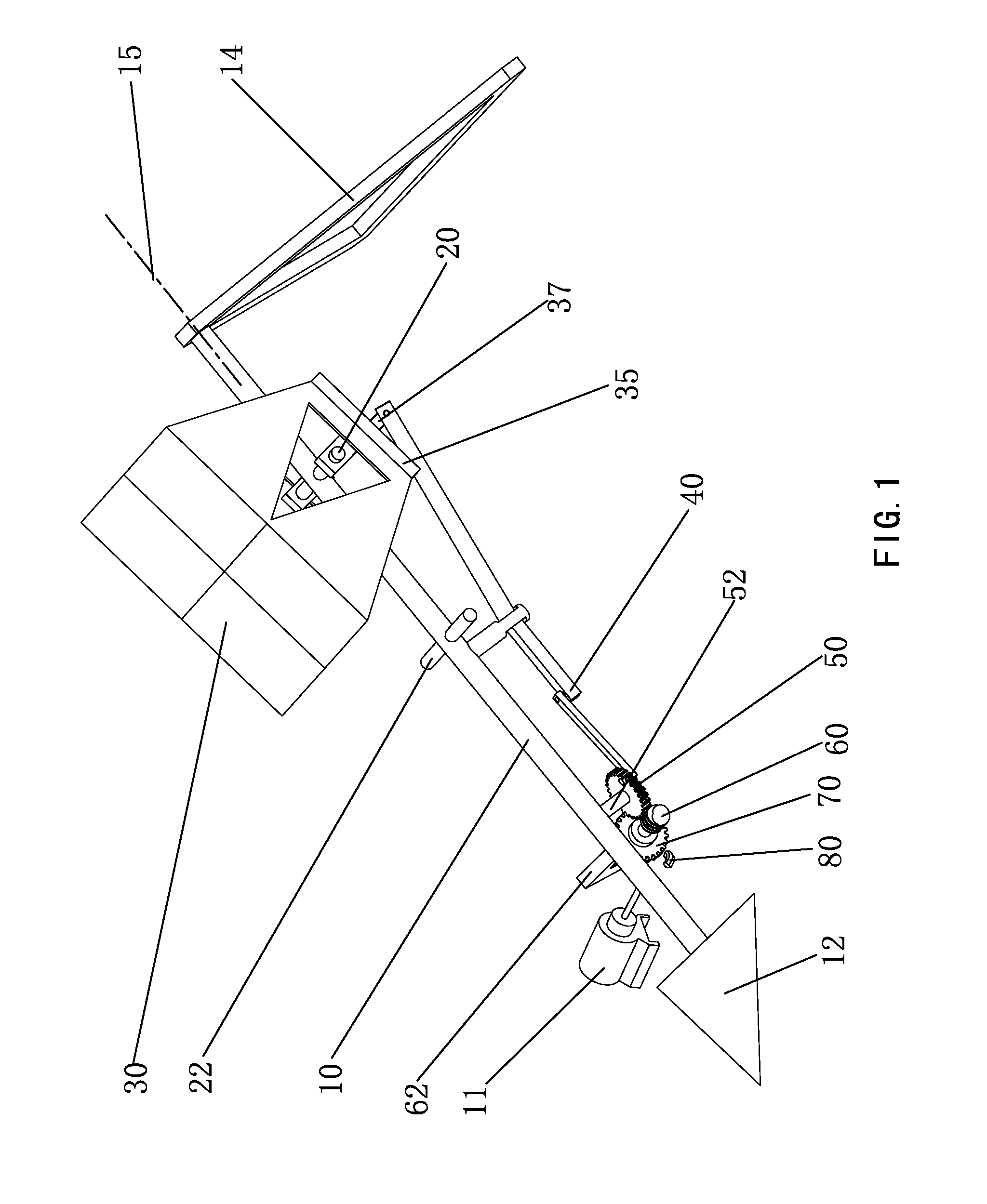

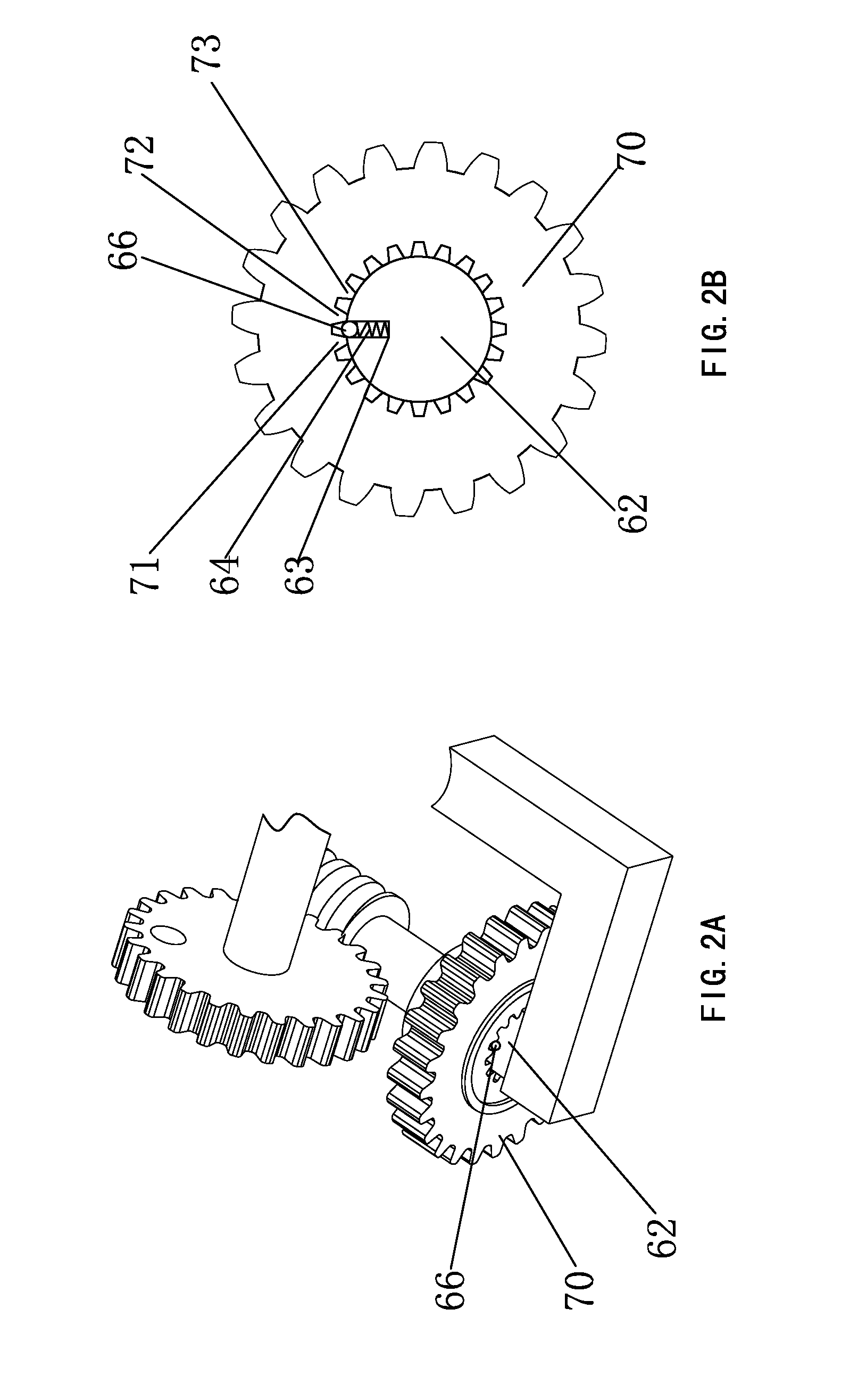

[0048]A 1-axis polar solar tracker is shown in FIG. 1, a rotatable shaft 10 is installed between a lower mount 12 and an upper support 14. Both 12 and 14 are fixed on the ground, and are installed in such a way that the shaft 10 can rotate along axis 15, which is essentially parallel to the celestial rotation axis of the Earth. Crossbars 20 and 22 are rigidly attached to the rotatable shaft 10, and the crossbars 20 and 22 are perpendicular to the rotatable shaft 10. There are more support beams 52 and 62 rigidly attached to the rotatable shaft 10. Solar energy collector 30 is mounted on the crossbar 20 and it could rotate around the crossbar 20 for at least ±23½°, which defines the declination angle. If we establish xyz coordinates here, center line of the shaft 10 as y-axis, center line of the crossbar 20 as x-axis, then we clearly know the z-axis is perpendicular to both x and y. the angle between the normal of the solar energy collector surface and the z-axis is the declination a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com