Clean feet foot wash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

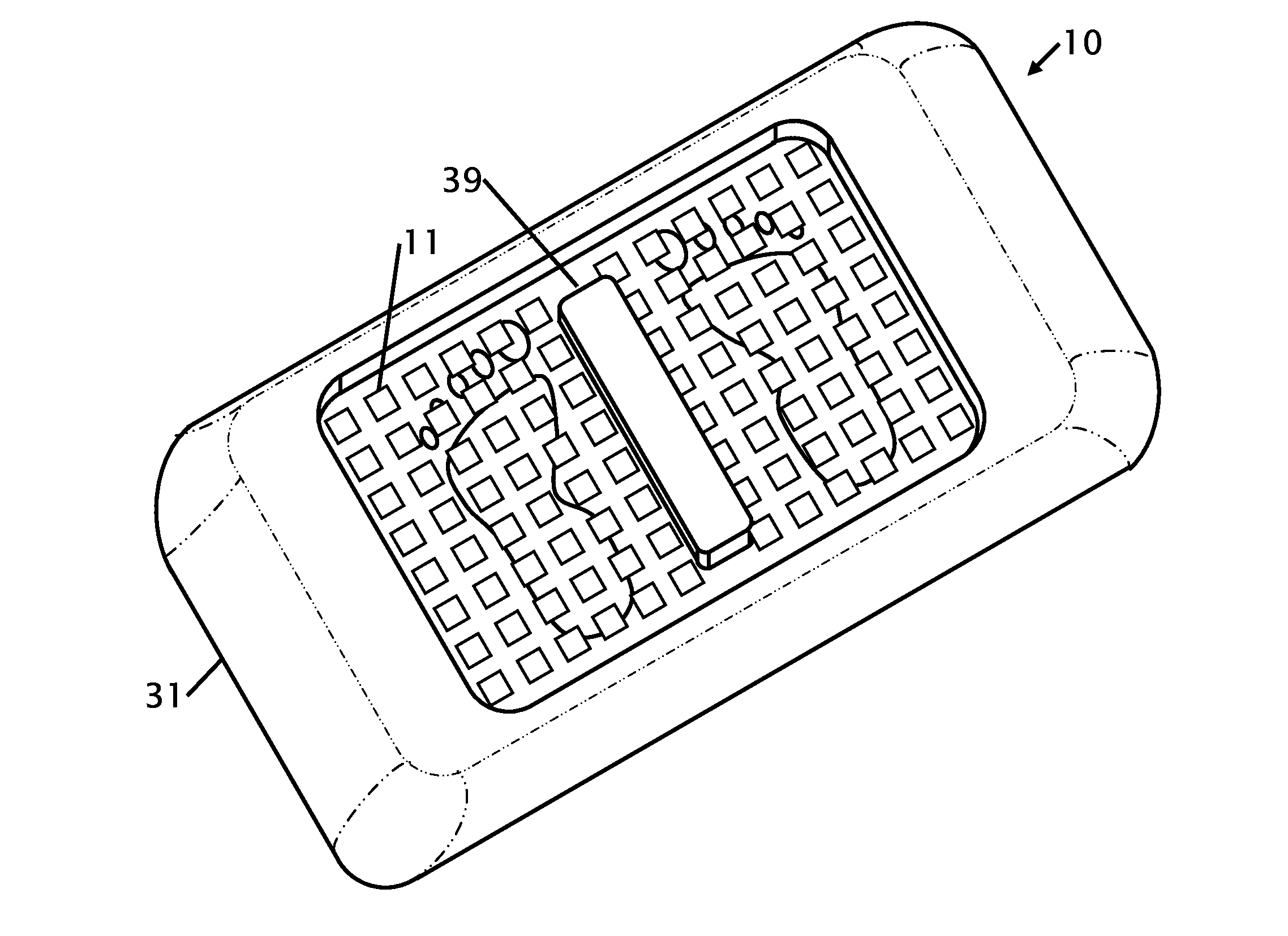

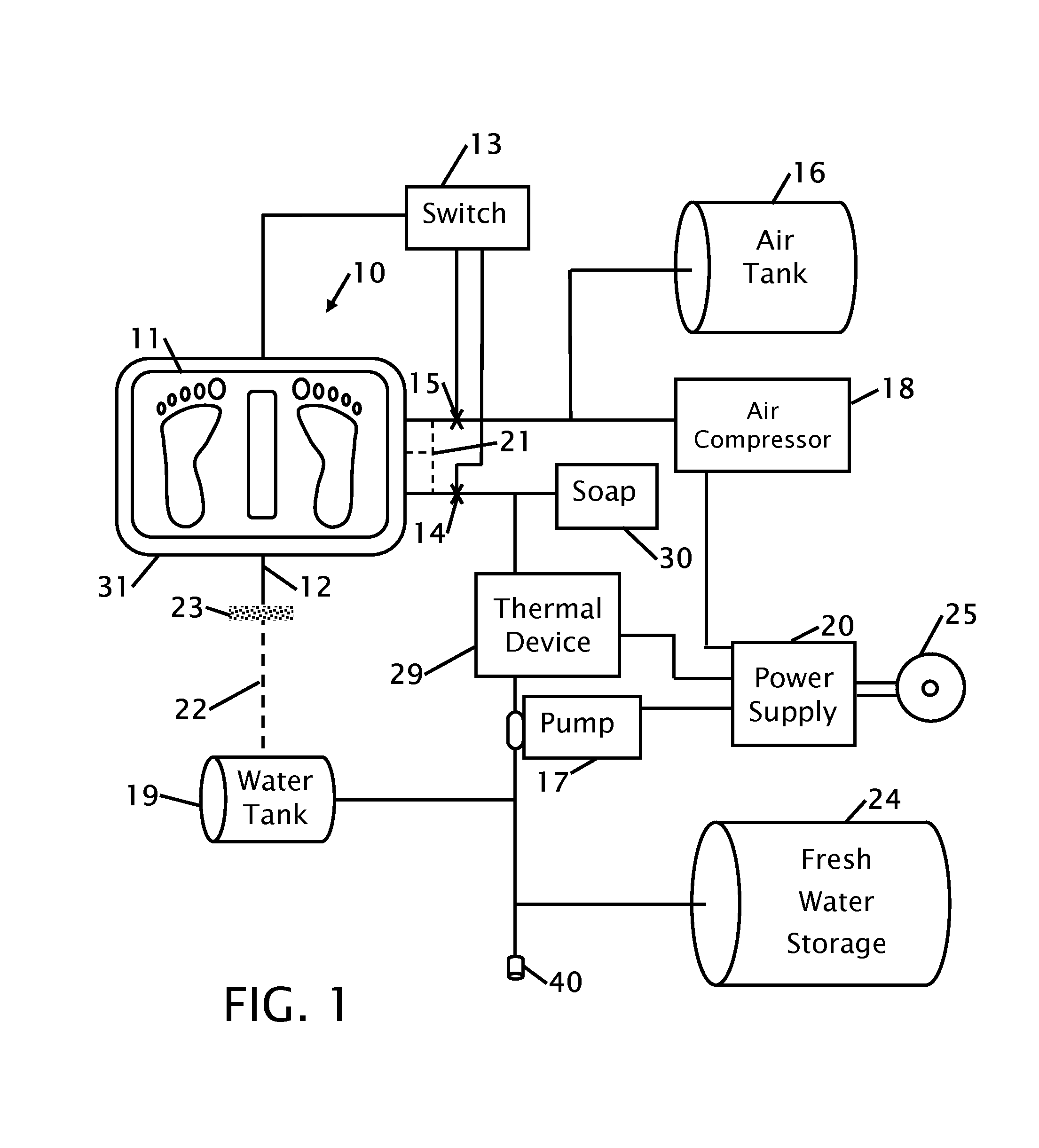

[0027]FIG. 1 shows a block diagram of the foot washing device 10. The foot washing device has a step pad or platform 11 in a basin 31 that is shown and described in FIGS. 2-8. The device is self contained where some or all of the components are enclosed within the basin. These components are shown in the block diagram outside of the basin, but are preferably enclosed within or in the underside of the basin. In general when sufficient weight is placed on the step pad 11 the weight activates a switching mechanism 13 that activates the device 10. The switch 13 opens a water valve 14 and or an air valve 15. In one embodiment the air and water flow through different lines into the basin 31. In an alternative embodiment the water and air lines are combined 21 where they flow into the basin 31.

[0028]The device 10 can be self contained with a power supply 20 such as a battery or can be powered from an external power supply 25. The external power supply 25 can charge the power supply 20 (bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com