Floating Cement Terminal

a floating cement terminal and cement technology, applied in waterborne vessels, special-purpose vessels, vehicles, etc., can solve the problems of increasing the number of waiting times, overcrowded ports or too small to handle current or increasing volumes, and affecting the supply of cement by cement manufacturers and cement suppliers. , to achieve the effect of reducing the waiting tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

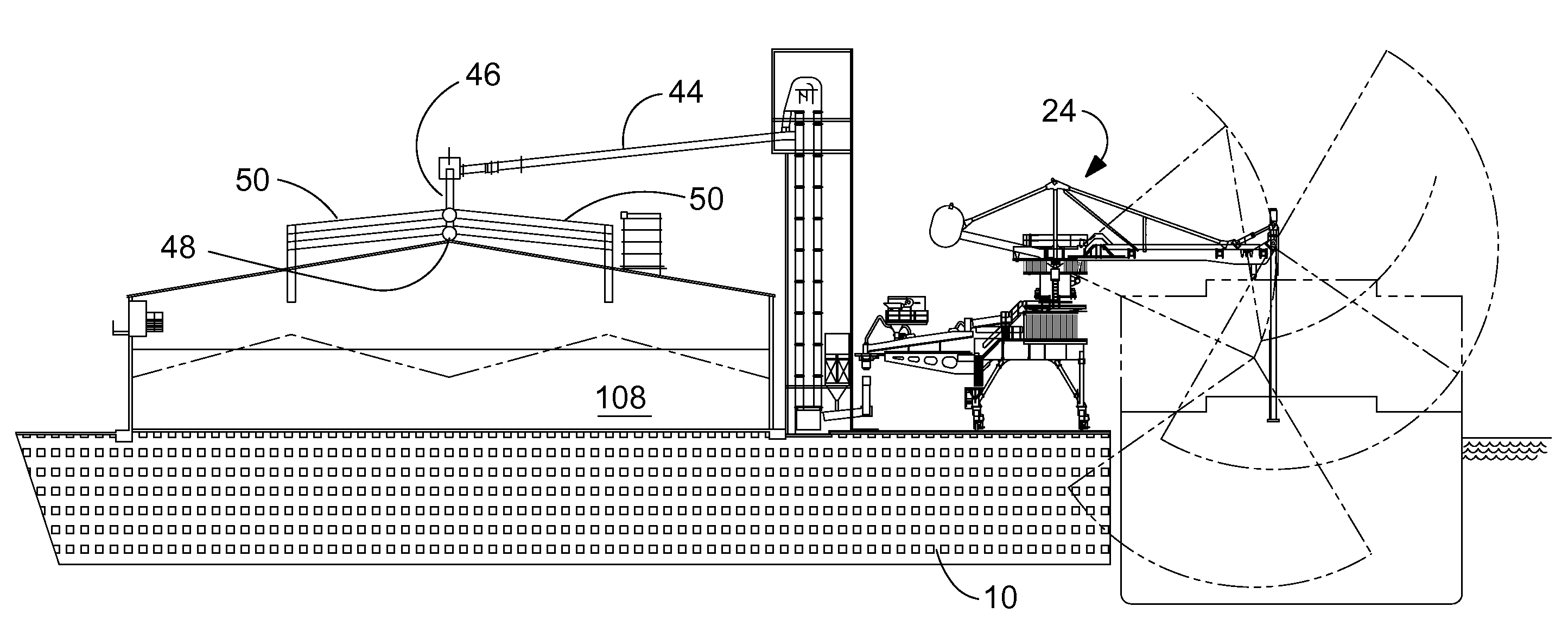

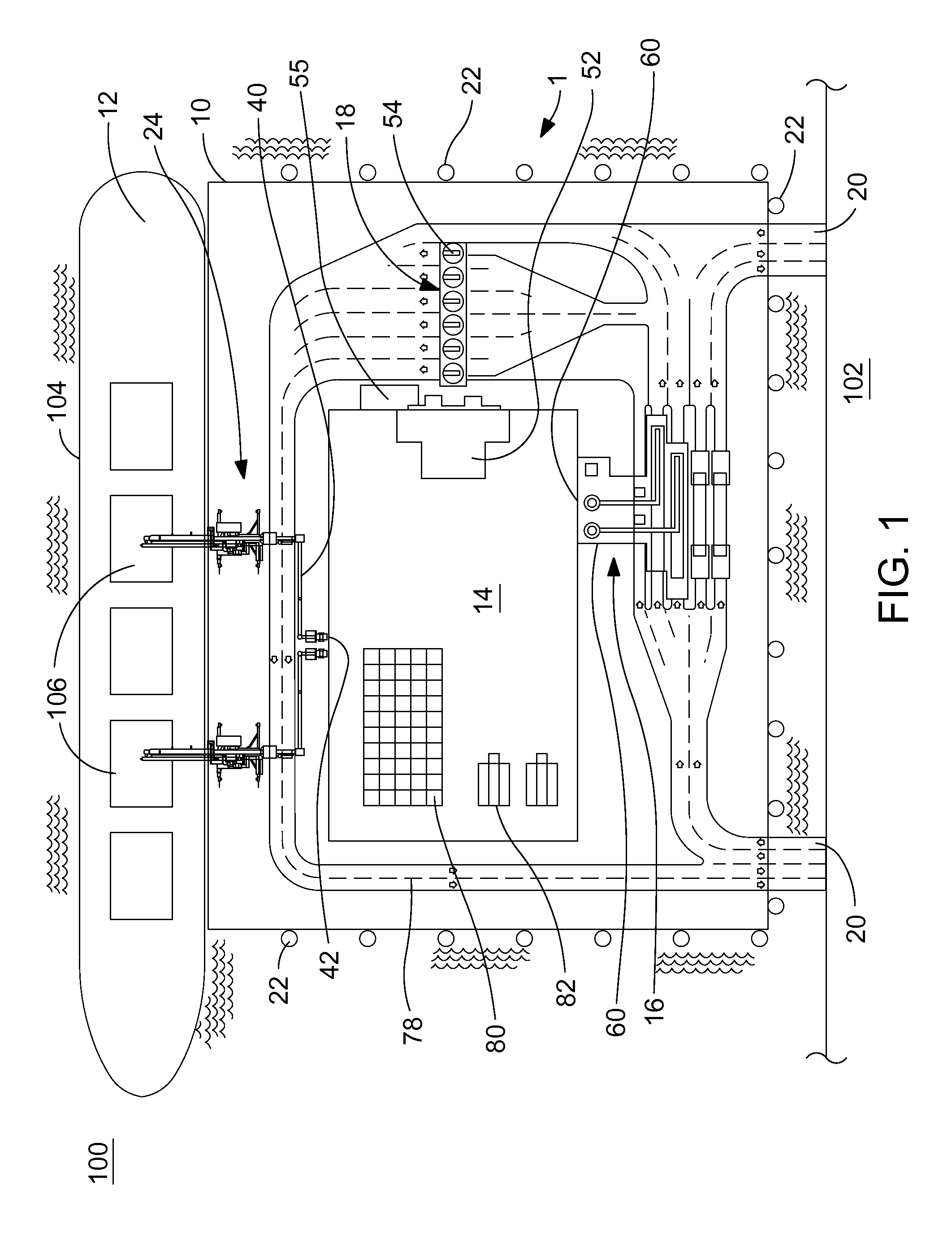

[0052]With reference now to the drawings, and particularly to FIG. 1, there is shown a top view of a floating cement terminal 1. With reference to FIG. 2, the floating cement terminal 1 preferably includes a floating pontoon 10, at least one ship docking station 12, a cement storage warehouse 14, a cement packing station 16, a bulk cement loading station 18 and at least one vehicle ramp 20. The floating pontoon 10 is preferably fabricated from concrete for floating in a body of water 100. The floating pontoon 10 acts as a platform for the floating cement terminal 1. The floating pontoon 10 may be purchased from International Marine Floating Structures, www.floatingstructures.com. The floating pontoon 10 is retained on a body of water and adjacent a land mass 102, preferably with a plurality of bollards 22 positioned around a perimeter of the floating pontoon 10. The at least one vehicle ramp 20 allows vehicles access to the floating pontoon 10 from the land mass 102.

[0053]The ship d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com