Purification of proteins

a technology of proteins and purification, applied in the field of recombinant proteins, can solve the problems of impossible removal of excess polyelectrolyte, difficult to predict exact level of impurities in the broth,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

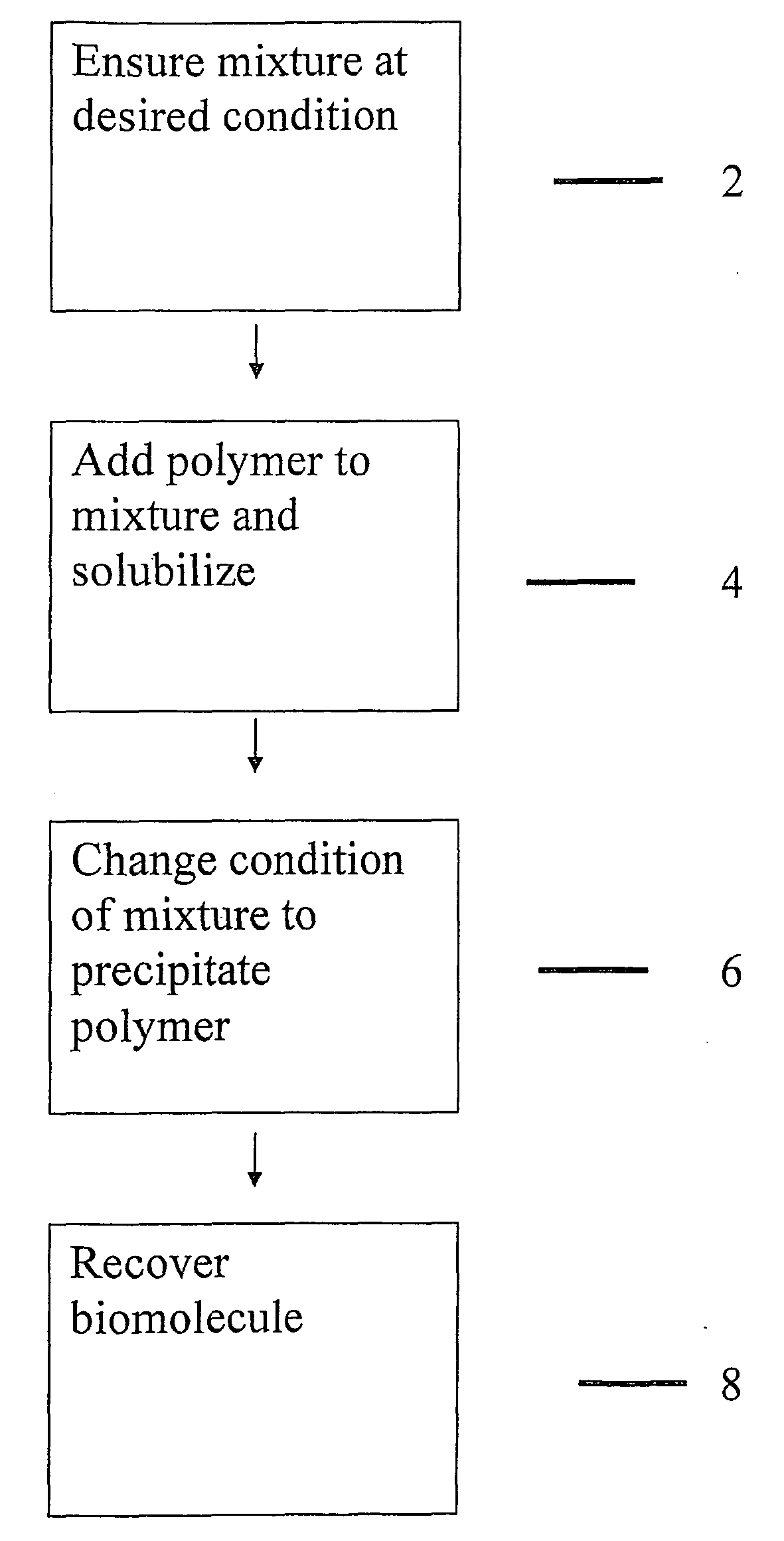

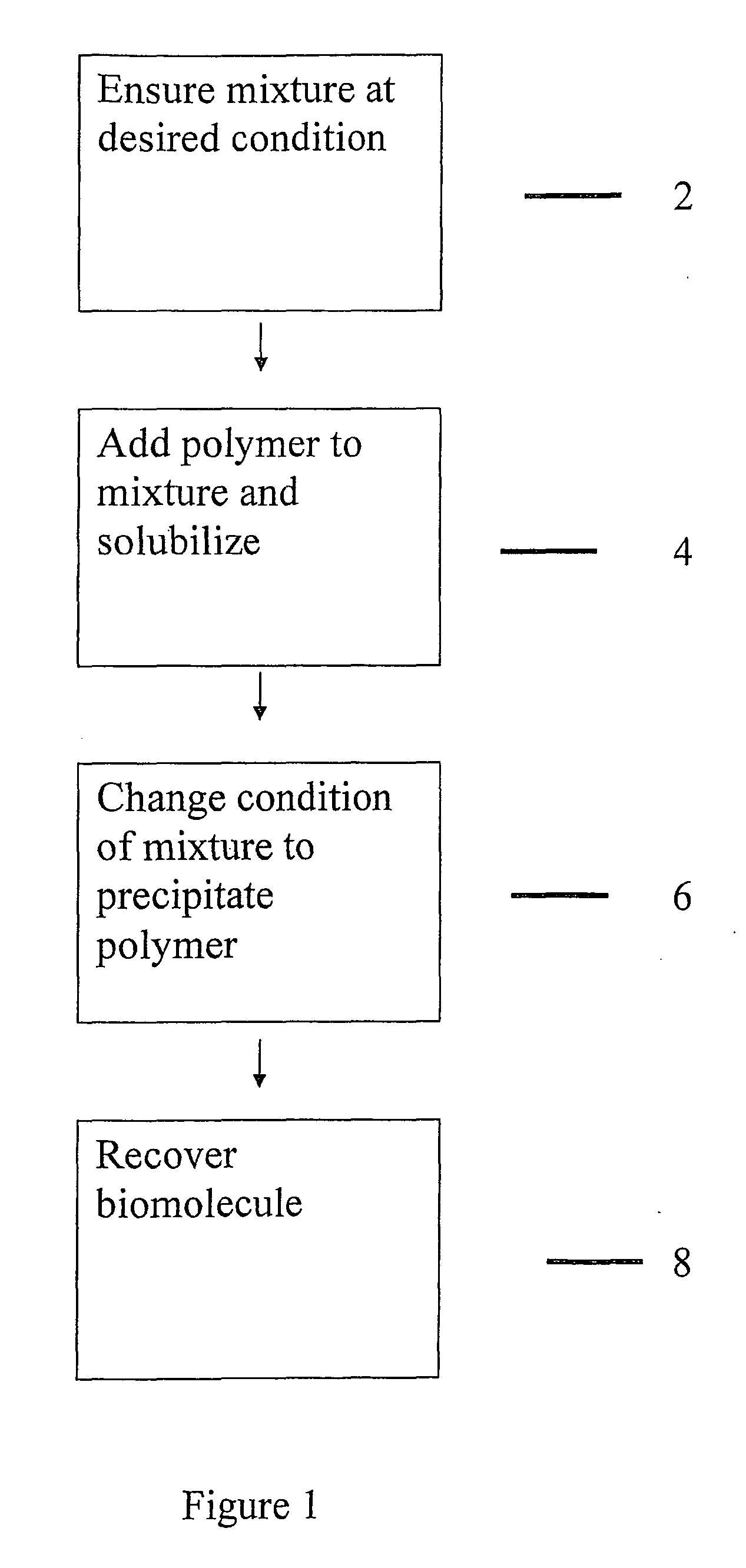

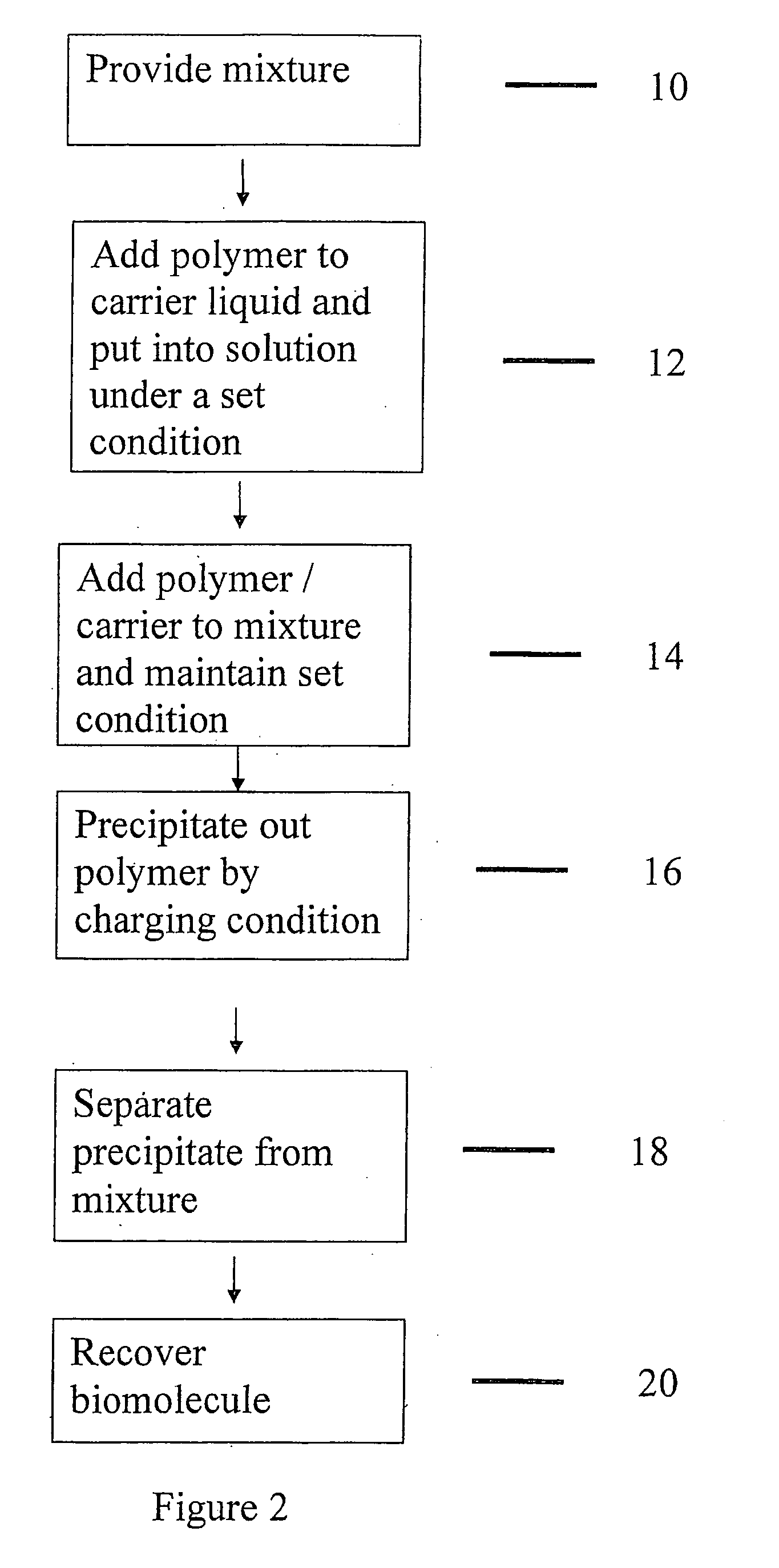

Method used

Image

Examples

example 2

[0172]This example illustrates the removal of residual 2-vinyl pyridine monomer from poly(2-vinylpyridine).

[0173]Linear poly(2-vinylpyridine), (P2VP) MW 200,000 obtained form Scientific Polymer Products, Inc., was treated exactly according to the process of example 1. The resulting polymer did not have a noticeable odor, whereas the untreated polymer has a distinct odor of 2-vinyl pyridine monomer.

example 3

[0174]This example illustrates the removal of residual 4-vinyl pyridine and styrene monomers from poly(4-vinylpyridine-co-styrene).

[0175]Linear poly(4-vinylpyridine-co-styrene), (P4VP-S), 10% styrene content, obtained form Scientific Polymer Products, Inc., was treated exactly according to the process of example 1. The resulting polymer did not have a noticeable odor, whereas the untreated polymer has a distinct odor of 4-vinyl pyridine and styrene monomers.

example 4

[0176]This example illustrates the preparation of a poly(4-vinylpyridine) (P4VP) solution.

[0177]A 20% (w / w) solution of P4VP was prepared by dissolving 20 g purified P4VP, from example 1, in 80 g 1.0 M hydrochloric acid with continuous agitation for 16 hours at room temperature. The resulting viscous solution was clear and had a slight yellow color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com