Energy harvester utilizing external magnetic field

a technology of energy harvester and magnetic field, which is applied in the direction of mechanical energy handling, mechanical equipment, machines/engines, etc., can solve the problems of unsatisfactory damping and noise generation, and achieve the effect of small and ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

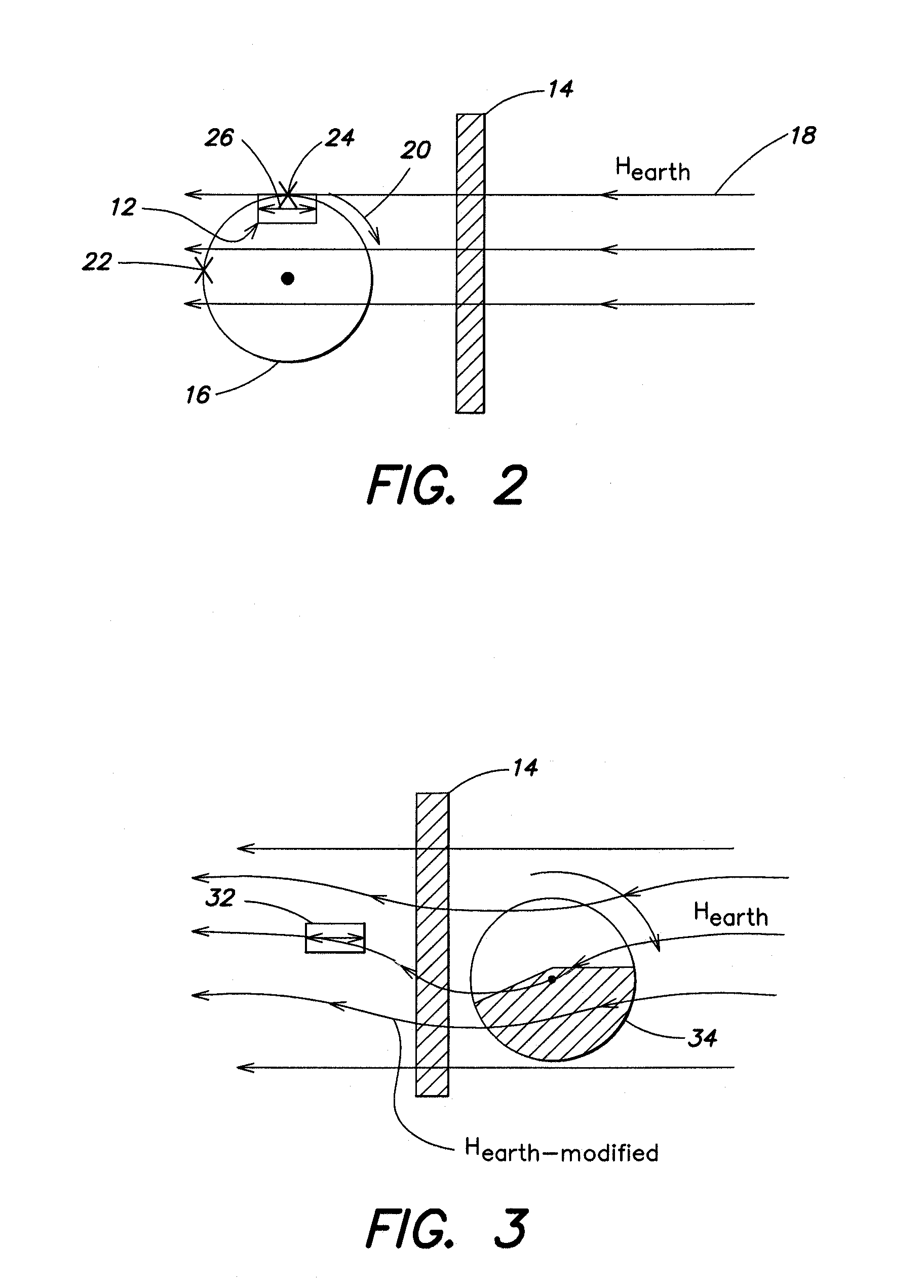

[0068]FIG. 2 illustrates an energy harvester device according to the invention, wherein a static external magnetic field, here Hearth (the earth's magnetic field), acts at a distance (or through a non-magnetic barrier) on a sensor whose orientation in the field changes with time. Thus, the flux density in the sensor is altered by changes in the physical orientation of the sensor with respect to the direction of the earth's field (or other substantially static field). FIG. 2 illustrates this with a non-magnetic barrier 14 separating the energy harvester 12 on the left, attached to a moving object (rotating machinery part 16), from the source of external field 18 on the right. The arrow 26 extending across the width of sensor 12 represents the plane of the magnetization vector M. The arrow 20 illustrates rotation of sensor 12 from a first position 22 (labeled X) to a second position 24 (labeled X′). Alternatively, the sensor can be attached to a rotating part on a vehicle, a door, or ...

second embodiment

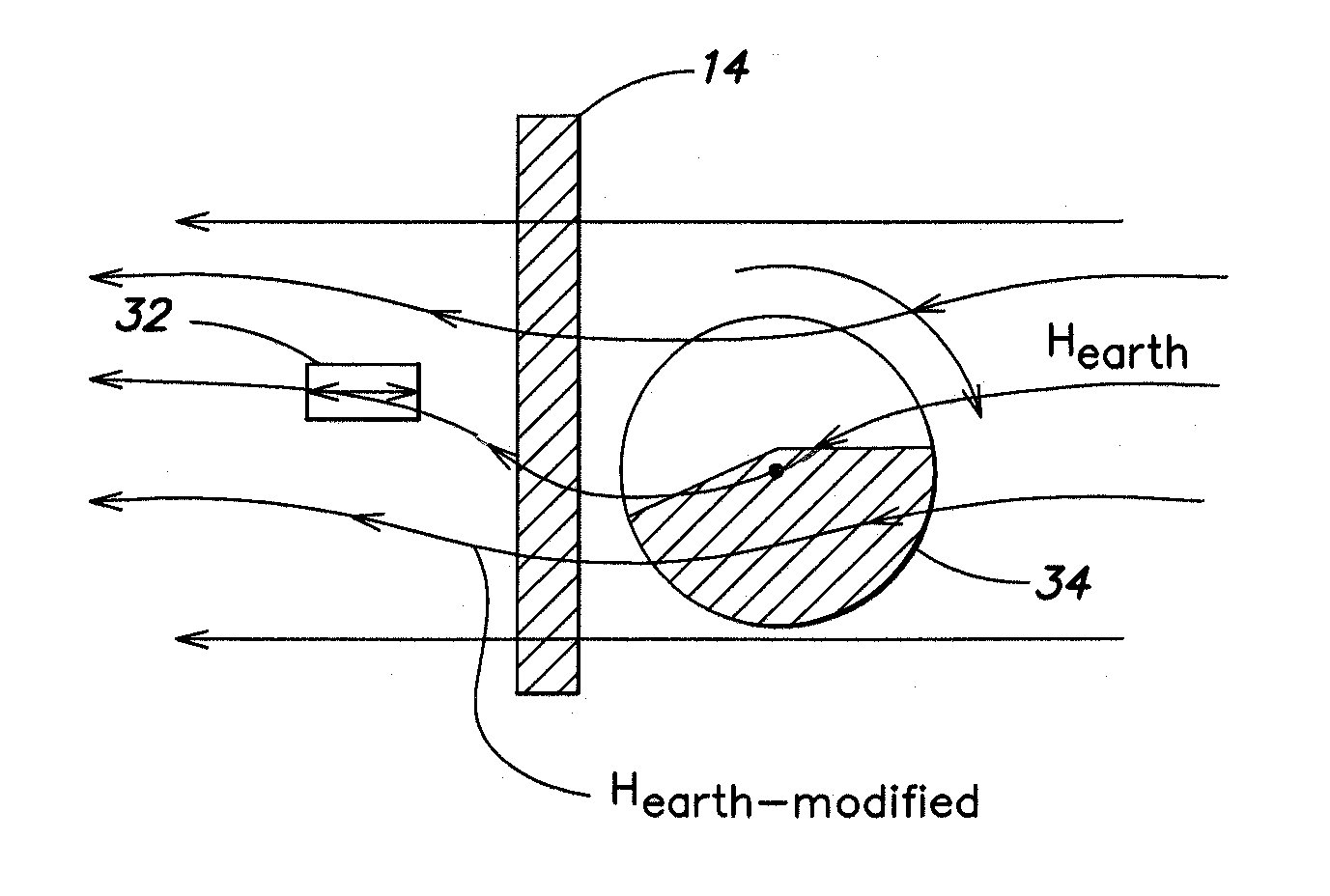

[0069]the invention is shown in FIG. 3, wherein a changing external field, Hearth-modified, acts at a distance (or through a non-magnetic barrier) on a stationary sensor 32. Here the orientation of the field at the sensor location changes with time. In FIG. 3, a moving magnetic object (rotating disk 34) in the path of the earth's ambient field causes a change in that field, and this changing field (Hearth-modified) then reaches (acts on) the static sensor 32.

[0070]In a further alternative embodiment, shown in FIG. 4, a permanent magnet 42 is affixed to a rotating or moving object 44 remote from the sensor 48. The change in position of the magnet 42 relative to the stationary sensor 48 causes a changing field (see field lines 46 of Hext) that acts on the static sensor 48. Arrow 45 illustrates rotation of the magnet to a second position (shaded area 42′ at the bottom of rotating disk 44) and the changing field as dashed lines 46′. Other sources of changing or alternating magnetic fiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequencies | aaaaa | aaaaa |

| stress-voltage coefficients | aaaaa | aaaaa |

| stress-voltage coefficients | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com