Humidity control apparatus and ventilation apparatus

a humidity control and air technology, applied in the field of humidity control apparatuses, can solve problems such as dehumidification of air, and achieve the effects of reducing the space for containing the compressor, facilitating maintenance of the humidity control apparatus, and being easy to remov

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Advantages of First Embodiment

[0164]In the first embodiment, the adsorption heat exchangers (14, 15) as an adsorption member for controlling humidity of the air, and the other components and the refrigerant pipes, etc., of the refrigerant circuit (11) are integrally held in the drawer unit (50), and the drawer unit (50) can be drawn out of the casing (20). Therefore, the maintenance worker can draw out the components out of the casing (20) merely by drawing the drawer unit (50) out. This allows for easy maintenance of the adsorption heat exchangers (14, 15), etc. In drawing the drawer unit (50) out, the worker does not have to detach and connect the refrigerant pipes. This can greatly improve the ease of maintenance of the humidity control apparatus.

[0165]The arrangement of the compressor (12) inside the second humidity control chamber (66) allows for reduction of space for containing the compressor (12), thereby downsizing of the casing (20). Further, a distance between the compres...

second embodiment

of the Invention

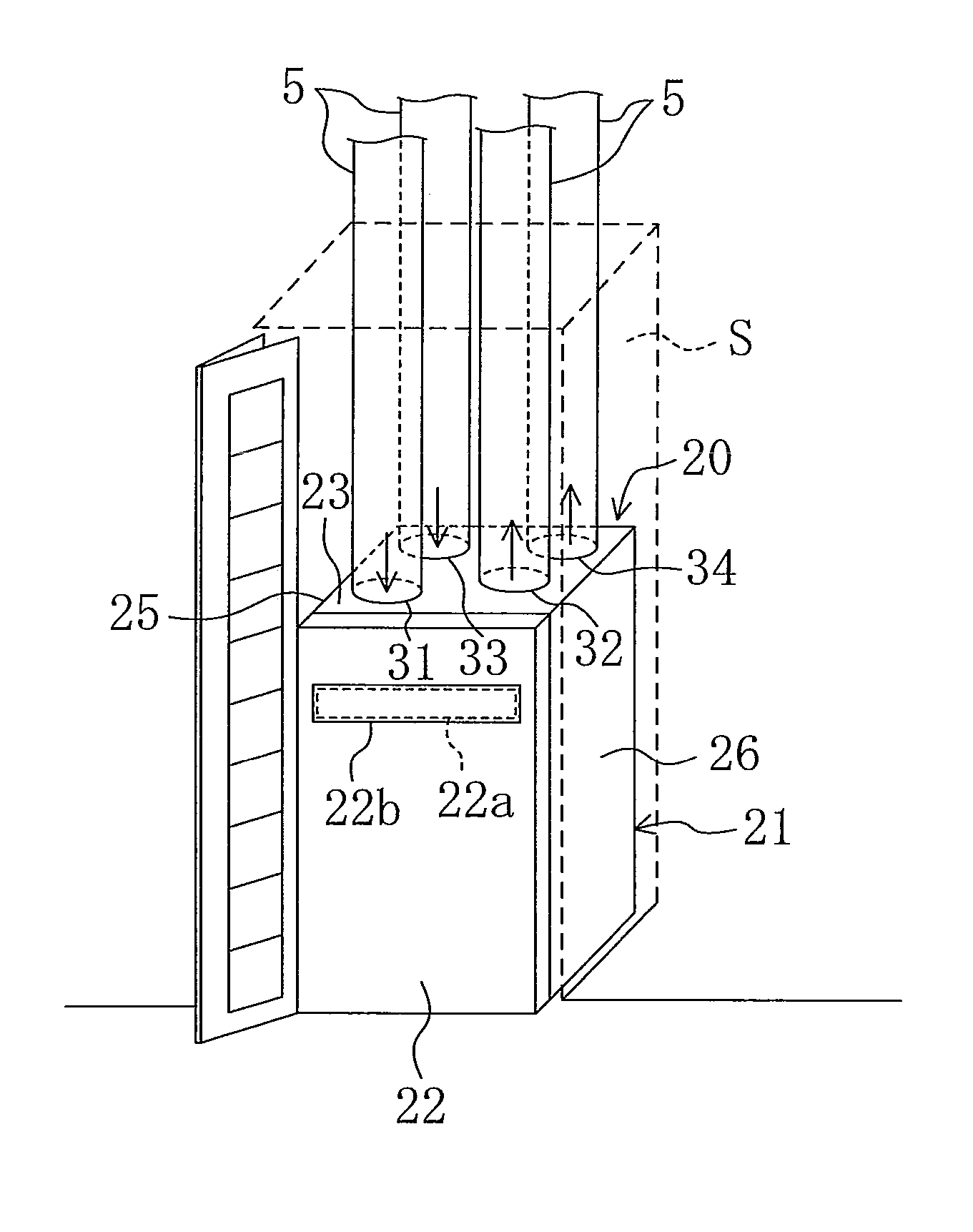

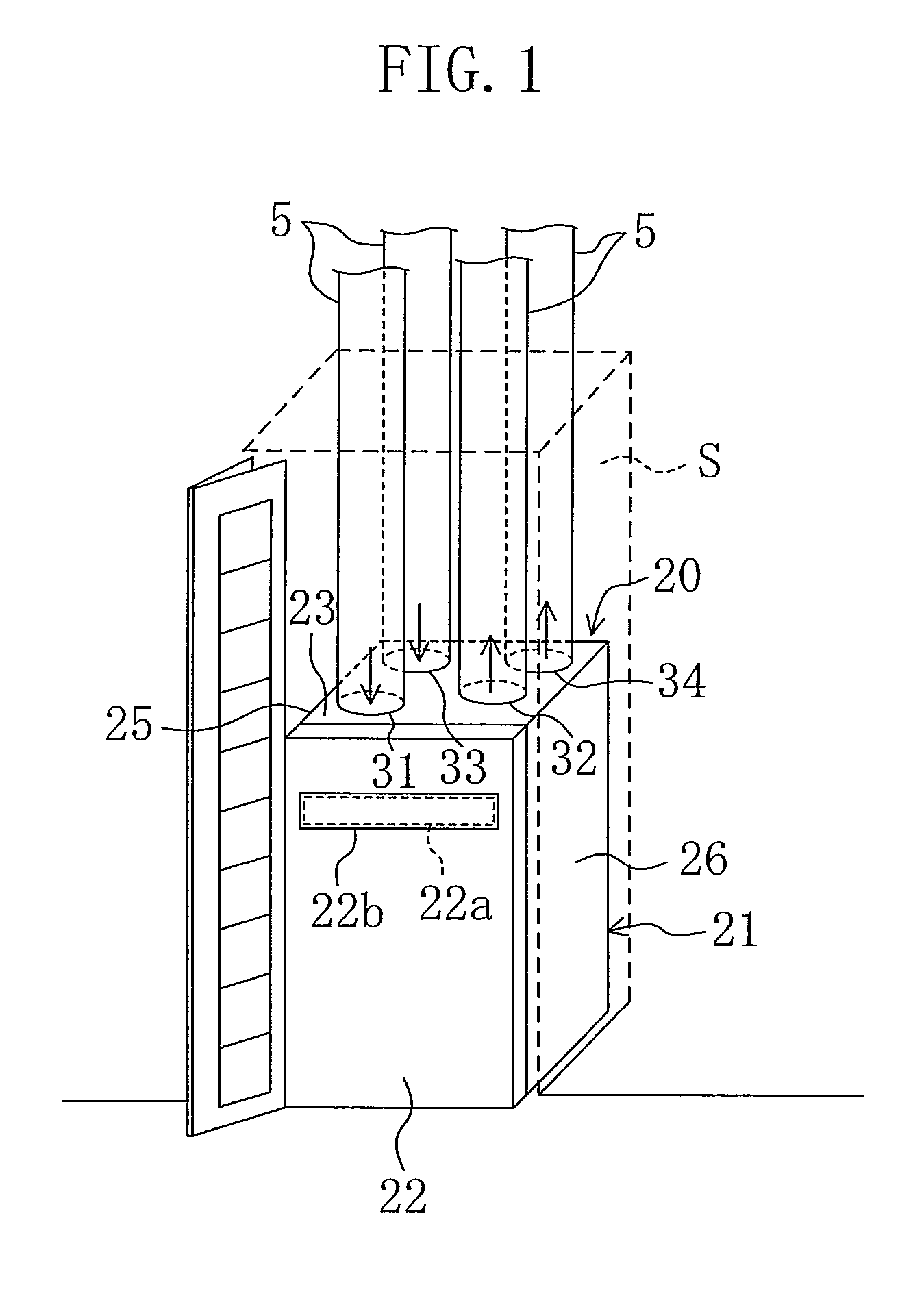

[0168]The structure of a humidity control apparatus (10) of a second embodiment is different from that of the humidity control apparatus of the first embodiment. The difference between the humidity control apparatus (10) of the second embodiment and that of the first embodiment will be described below. The humidity control apparatus (10) of the second embodiment includes a flat, vertical casing (20), and is installed on a ceiling, for example.

[0169]As shown in FIG. 11, the casing (20) includes an outside air inlet port (31) formed in a lower center portion of a front side thereof (in an upper side in FIG. 11(A)), and a room air inlet port (32) formed in a lower center portion of the front side thereof. The casing (20) further includes an outward discharge port (33) formed in a rear portion of a left side thereof, and an inward supply port (34) formed in a rear portion of a right side thereof. On the right side of the casing (20), a side cover (28) is detachably attac...

third embodiment

of the Invention

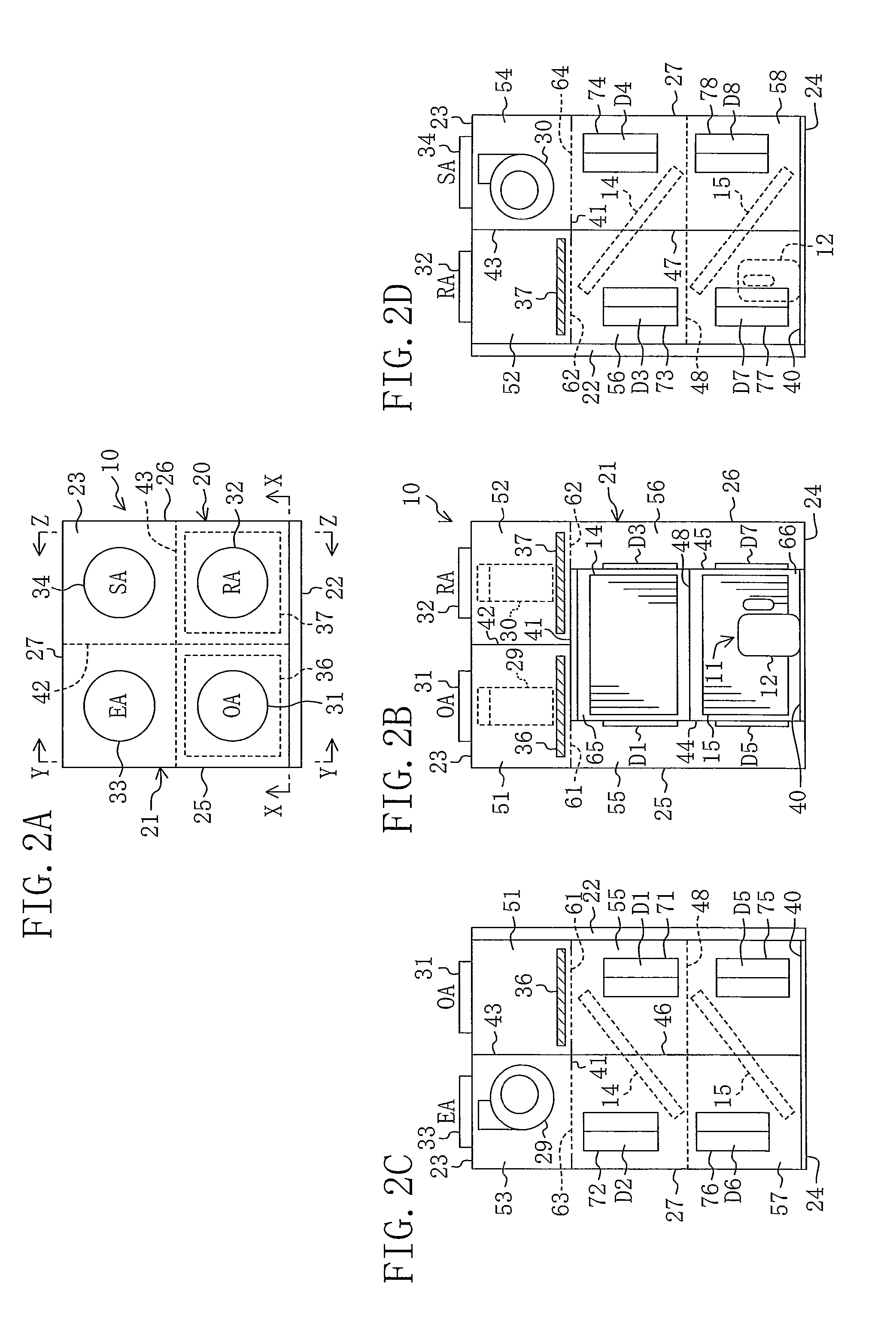

[0179]The structure of a humidity control apparatus (10) of a third embodiment is different from those of the humidity control apparatuses of the first and second embodiments. The humidity control apparatus (10) of the third embodiment humidifies or dehumidifies the air using a rotatable desiccant rotor (80). This humidity control apparatus (10) constitutes a ventilation humidity control apparatus in which humidity of outside air (OA) is controlled, and the humidity-controlled air is supplied to the inside of the room as supply air (SA), and simultaneously, room air (RA) is discharged outside the room as exhaust air (EA).

[0180]Specifically, as shown in FIG. 13, the humidity control apparatus (10) includes a casing (20), in which a first air passage (91) and a second air passage (92) are provided. An outside air inlet port (31) is formed on an entrance side of the first air passage (91), and an inward supply port (34) is formed on an exit side of the first air passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com