Chip deflector on a blade of a downhole reamer and methods therefore

a technology of expandable reamer and blade, which is applied in the direction of drilling machine, cutting machine, construction, etc., can solve the problems of expensive pistons, high cost, and inability to help blade retraction, and achieve the effect of enlarge the borehole diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The illustrations presented herein are, in some instances, not actual views of any particular reamer tool, cutting element, or other feature of a reamer tool, but are merely idealized representations that are employed to describe the present invention. Additionally, elements common between figures may retain the same numerical designation.

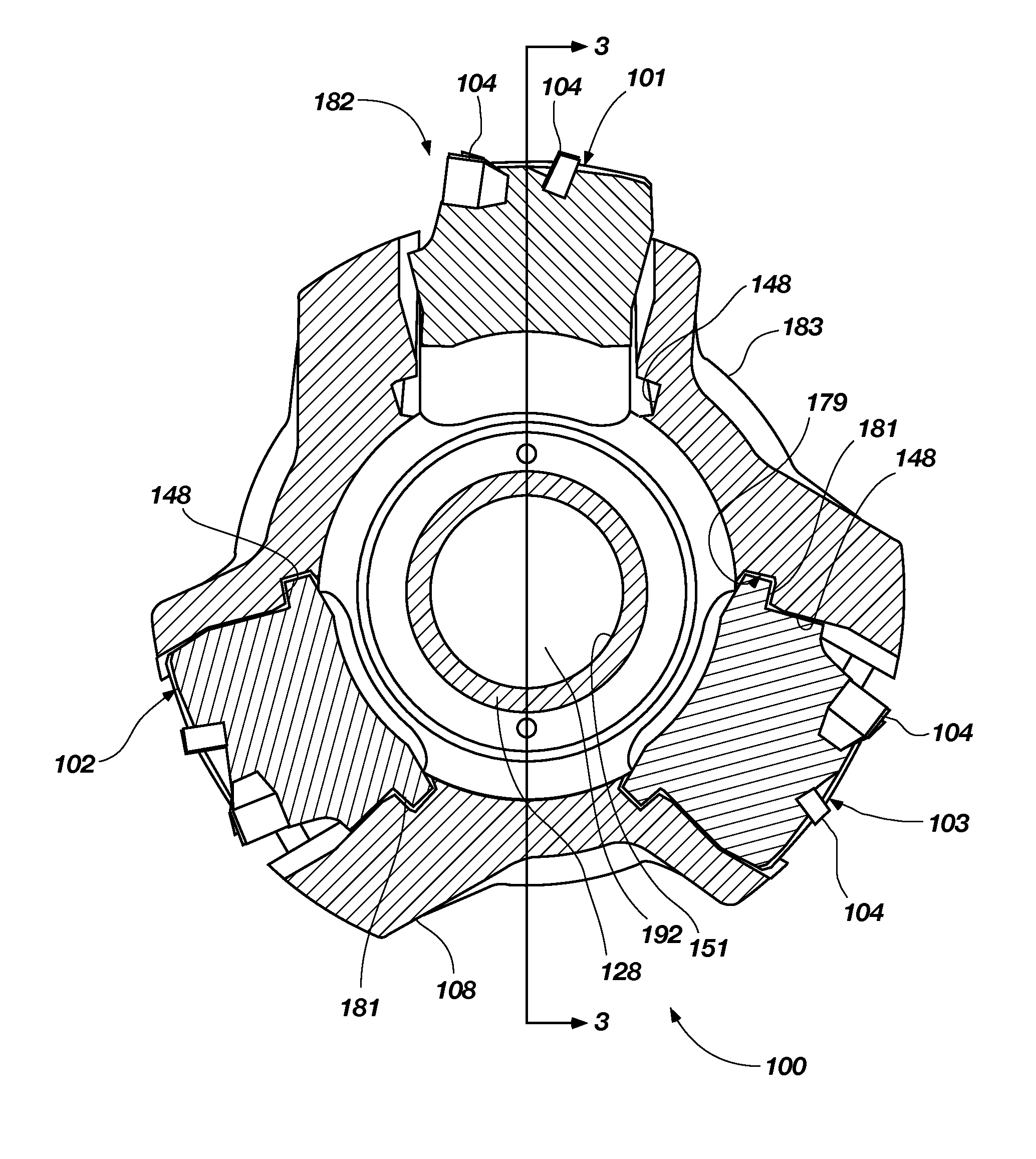

[0053]An expandable reamer apparatus 100 according to an embodiment of the invention is shown in FIG. 1. The expandable reamer apparatus 100 may include a generally cylindrical tubular body 108 having a longitudinal axis L8. The tubular body 108 of the expandable reamer apparatus 100 may have a lower end 190 and an upper end 191. The terms “lower” and “upper,” as used herein with reference to the ends 190, 191, refer to the typical positions of the ends 190, 191 relative to one another when the expandable reamer apparatus 100 is positioned within a well bore. The lower end 190 of the tubular body 108 of the expandable reamer apparatus 100 may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com