Headspace sealing and displacement method for removal of vacuum pressure

a vacuum pressure and headspace sealing technology, applied in the field of lightweighting hot fill containers, can solve the problems of vacuum pressure, reduced volume of liquid in containers, and vacuum pressure in containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]The following description of preferred embodiments is merely exemplary in nature, and is in no way intended to limit the invention or its application or uses.

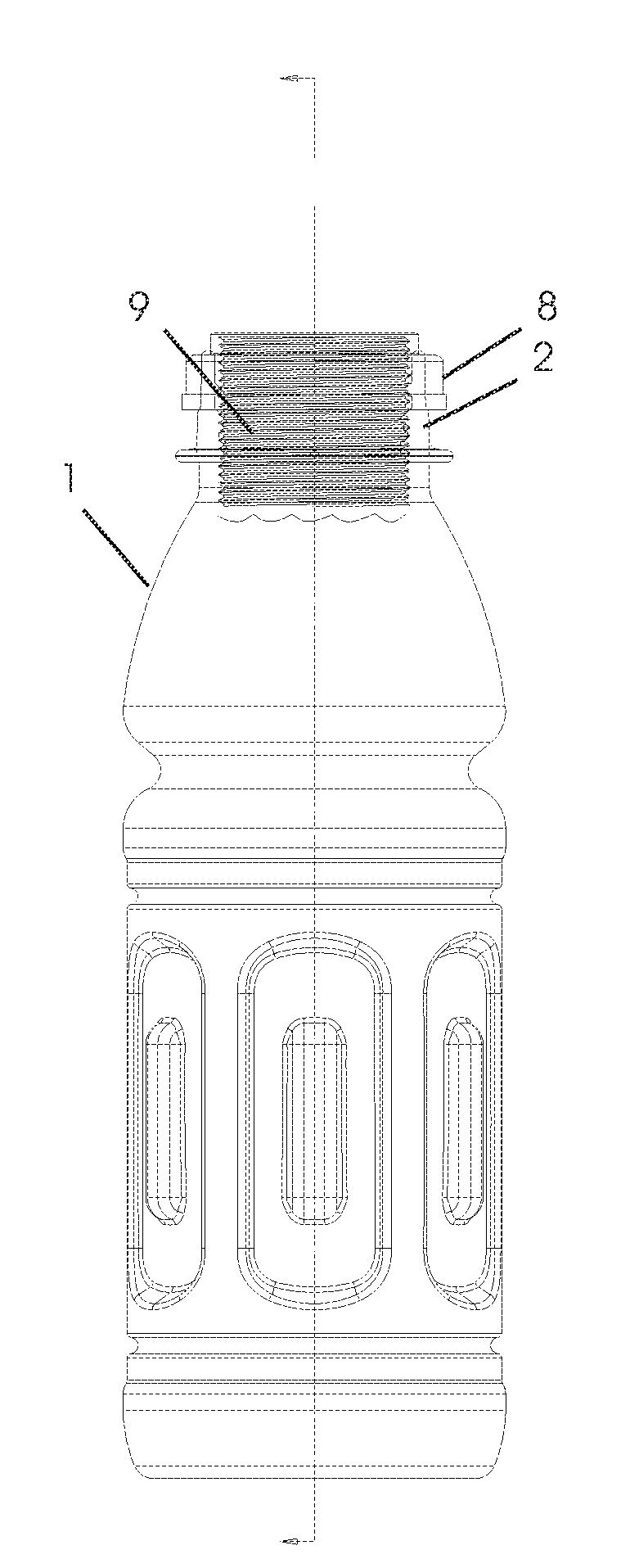

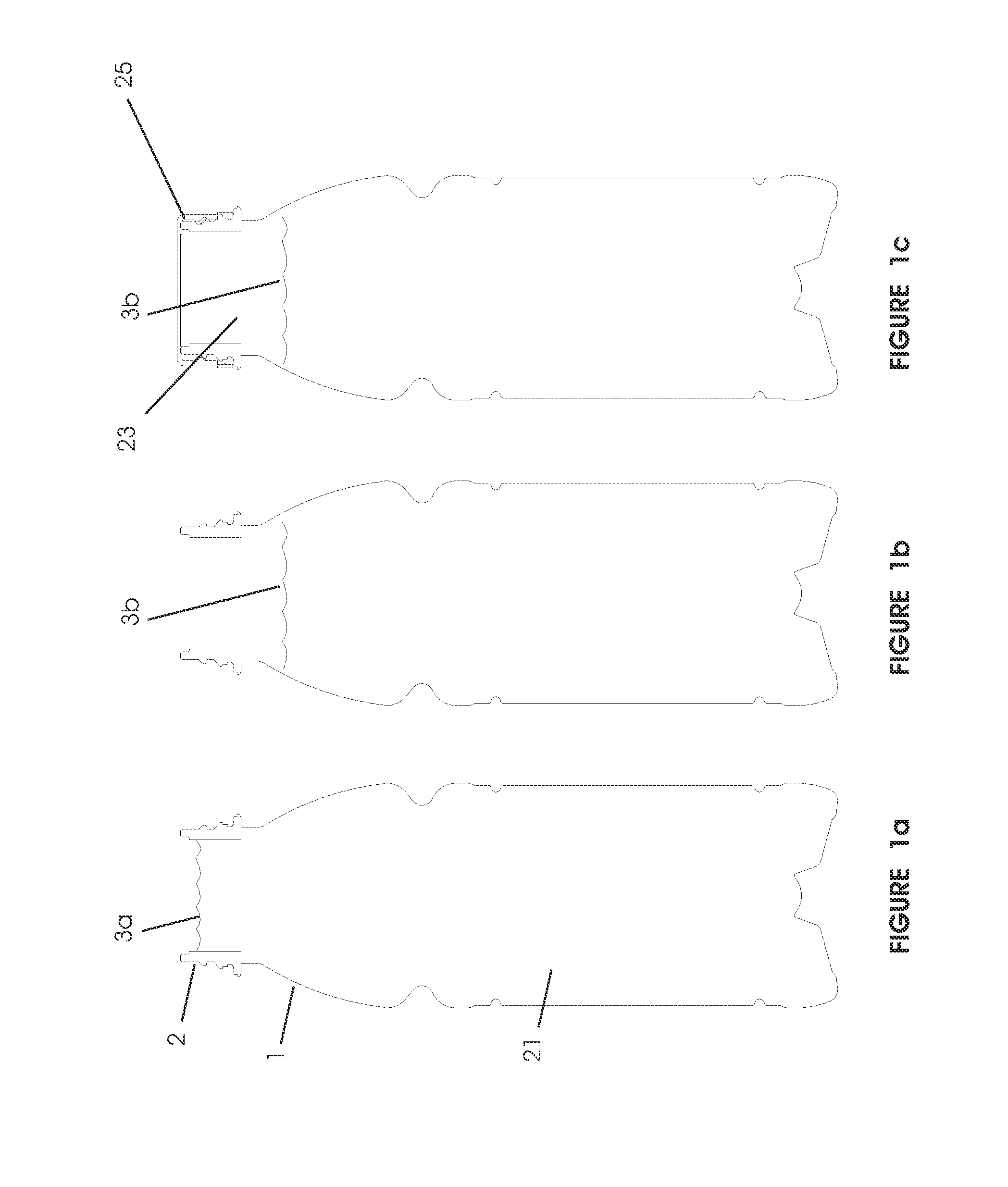

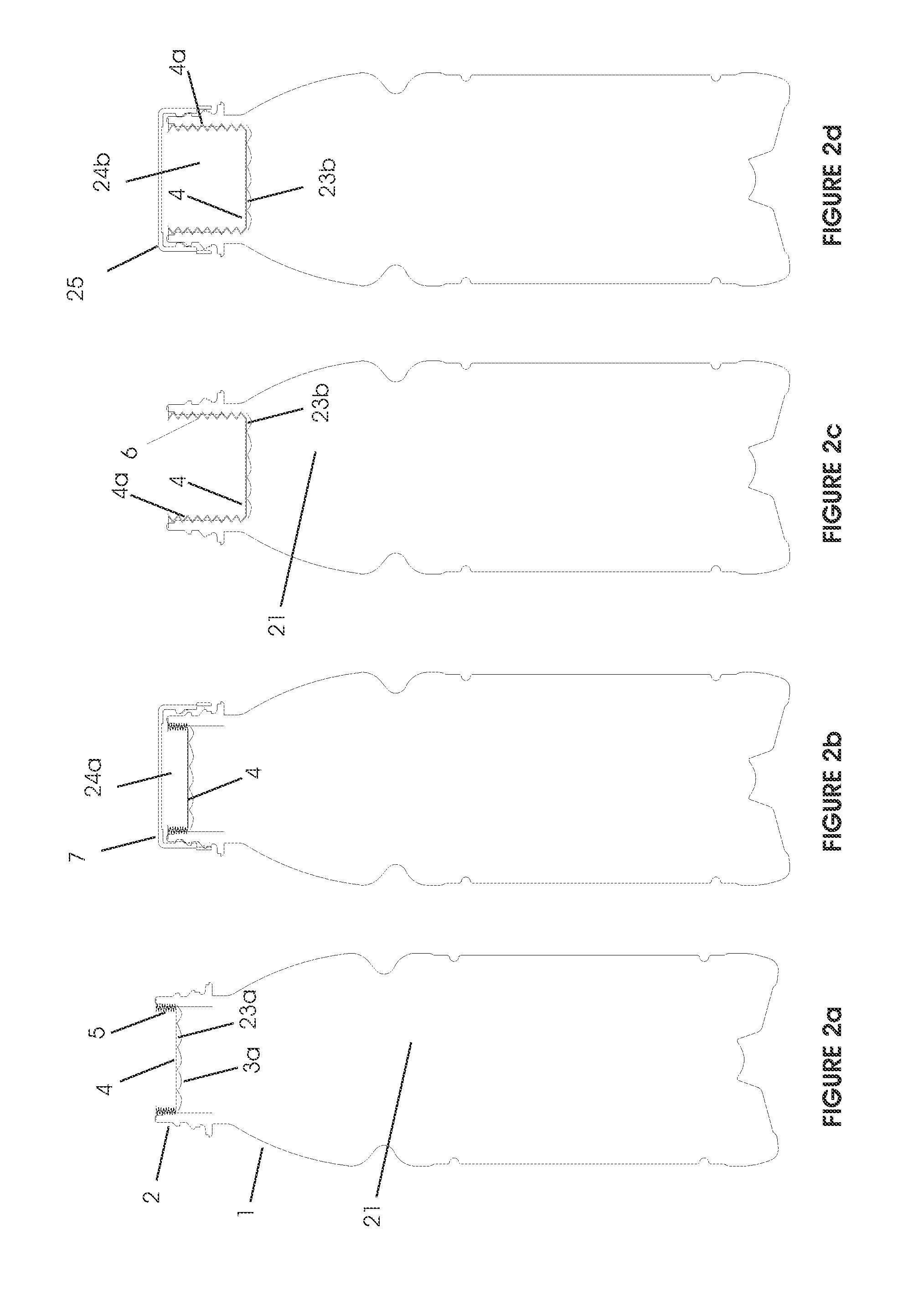

[0058]As discussed above, to accommodate vacuum forces during cooling of the contents within a heat set container, containers have typically been provided with a series of vacuum panels around their sidewalls and an optimized base portion. The vacuum panels deform inwardly, and the base deforms upwardly, under the influence of the vacuum forces. This prevents unwanted distortion elsewhere in the container. However, the container is still subjected to internal vacuum force. The panels and base merely provide a suitably resistant structure against that force. The more resistant the structure the more vacuum force will be present. Additionally, end users can feel the vacuum panels when holding the containers.

[0059]Typically at a bottling plant the containers will be filled with a hot liquid and then capped before being subje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| vacuum pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com