Surface plasmon wavelength converter

a surface plasmon and wavelength converter technology, applied in the field of wavelength converters, can solve the problems of high manufacturing cost of prior art wavelength conversion layers and relatively inefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

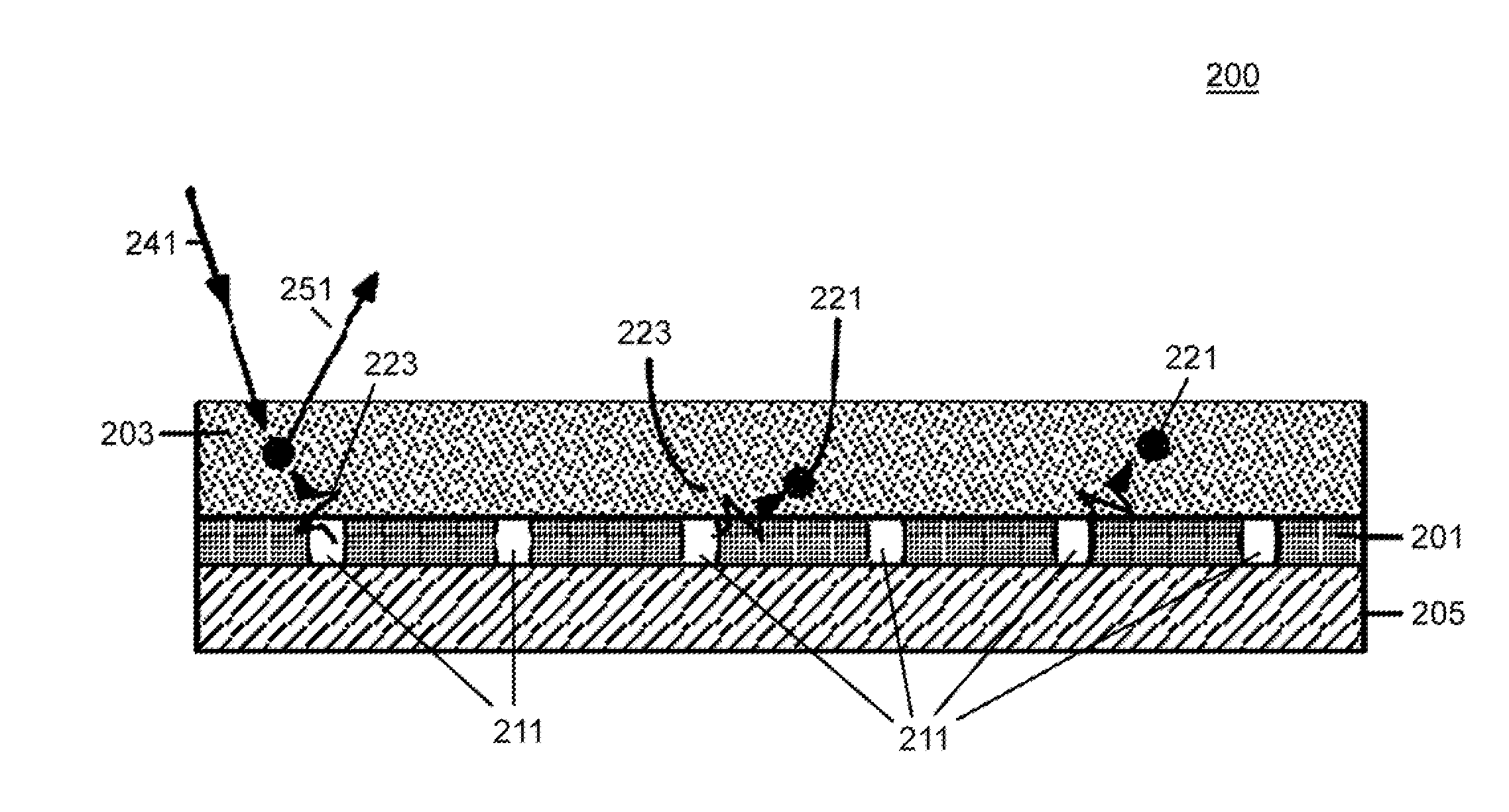

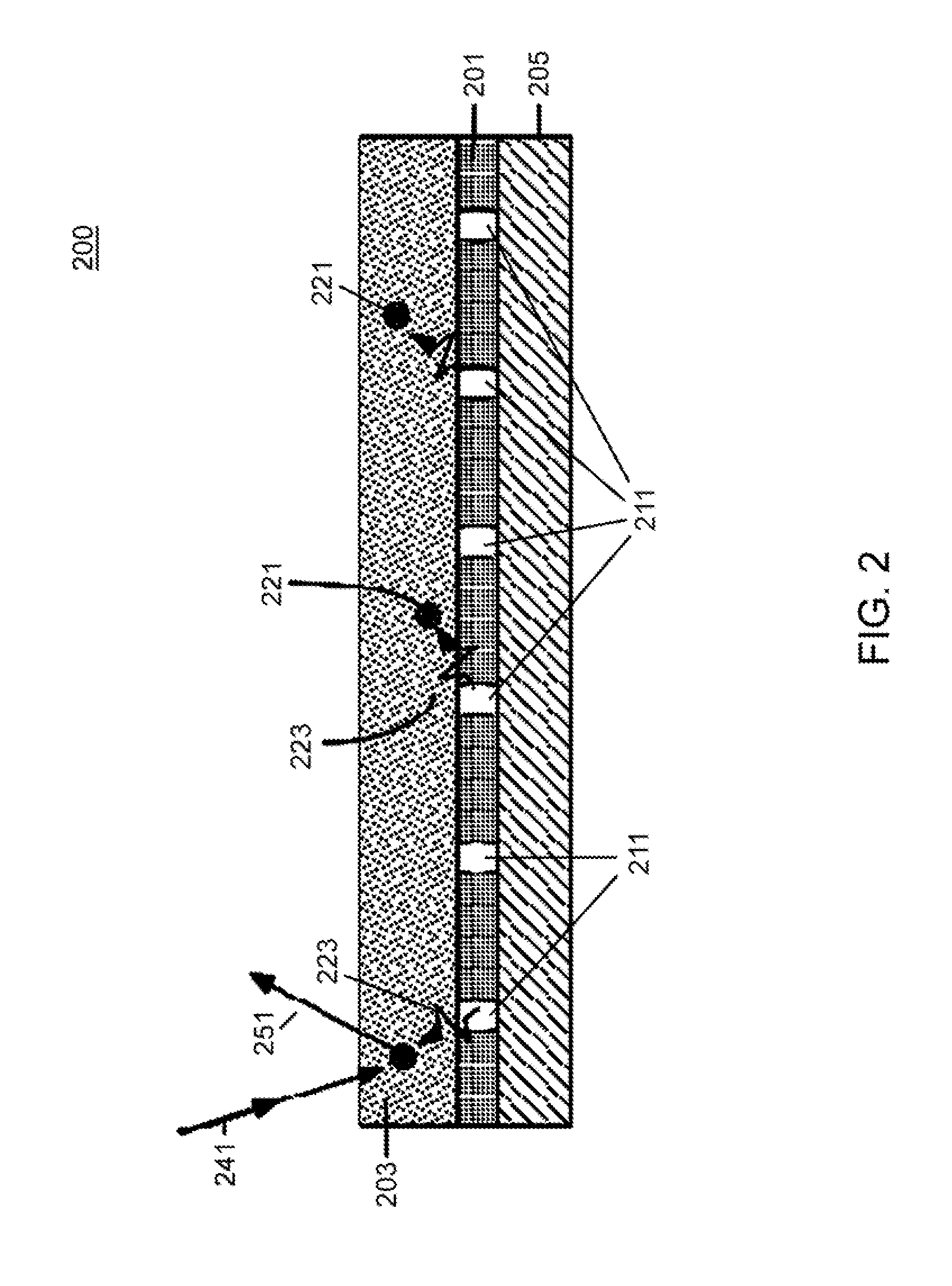

[0089]FIG. 11 shows an illustration of another exemplary embodiment of an integrated solar cell 1100 using stacked layers. Integrated solar cell 1100 includes surface plasmon wavelength converter structure 1110 and surface plasmon wavelength converter structure 1130. Surface plasmon wavelength converter structure 1110 includes a nanofeature layer 1101 having nanofeatures 1111, wavelength conversion layer 1103, and nanofeature layer 1105 having nanofeatures 1141. Surface plasmon wavelength converter structure 1130 includes a nanofeature layer 1131 having nanofeatures 1151, wavelength conversion layer 1133, and nanofeature layer 1135 having nanofeatures 1161. As described hereinabove, nanofeatures 1111, 1141, 1151, and 1161 can include any suitable nanohole pattern including positive and negative patterns such as, triangle, stars, posts, etc. Surface plasmon wavelength converter structure 1110 serves as a downconversion layer at a first surface (e.g. nearer to the front surface of sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com