Foam Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

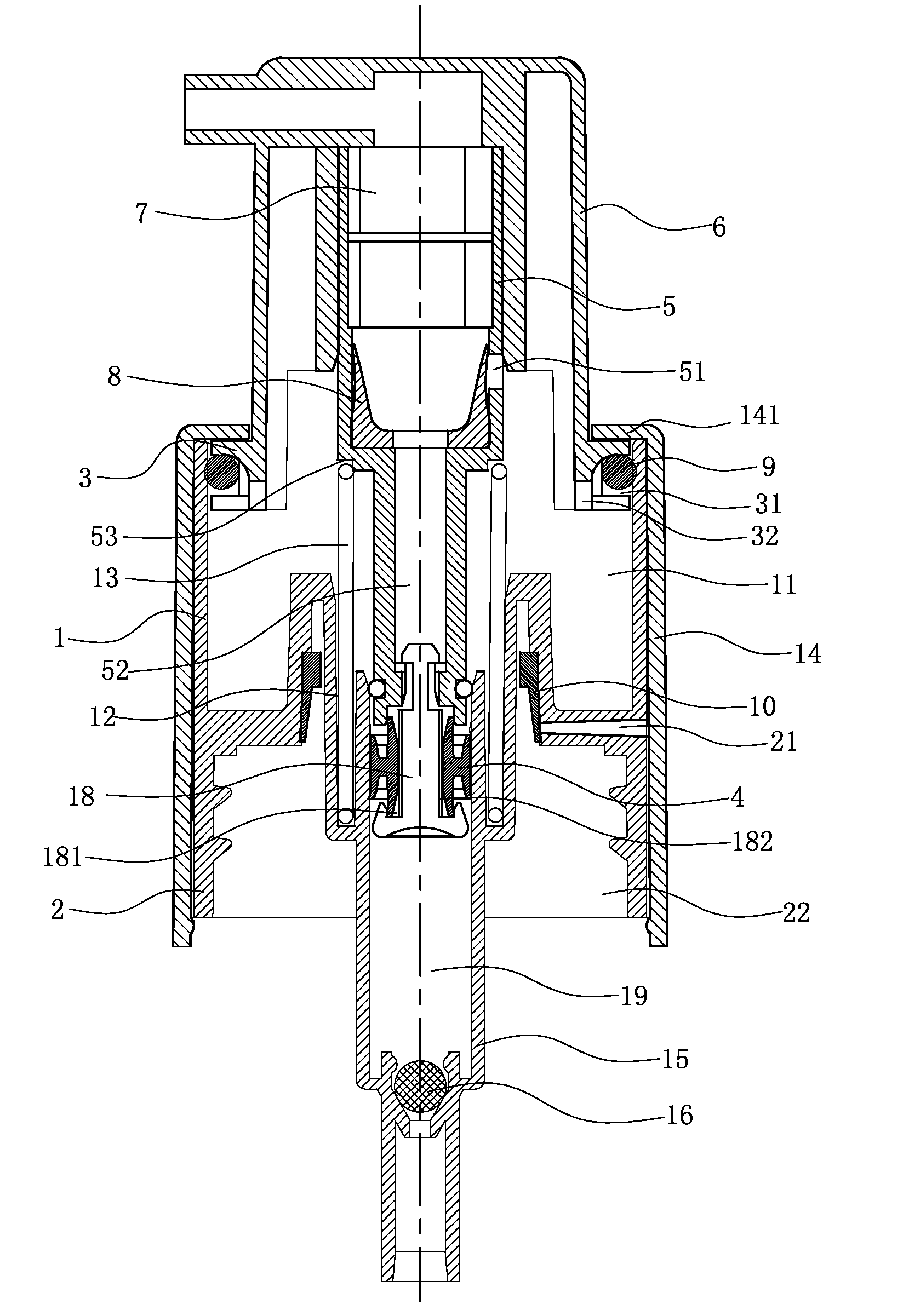

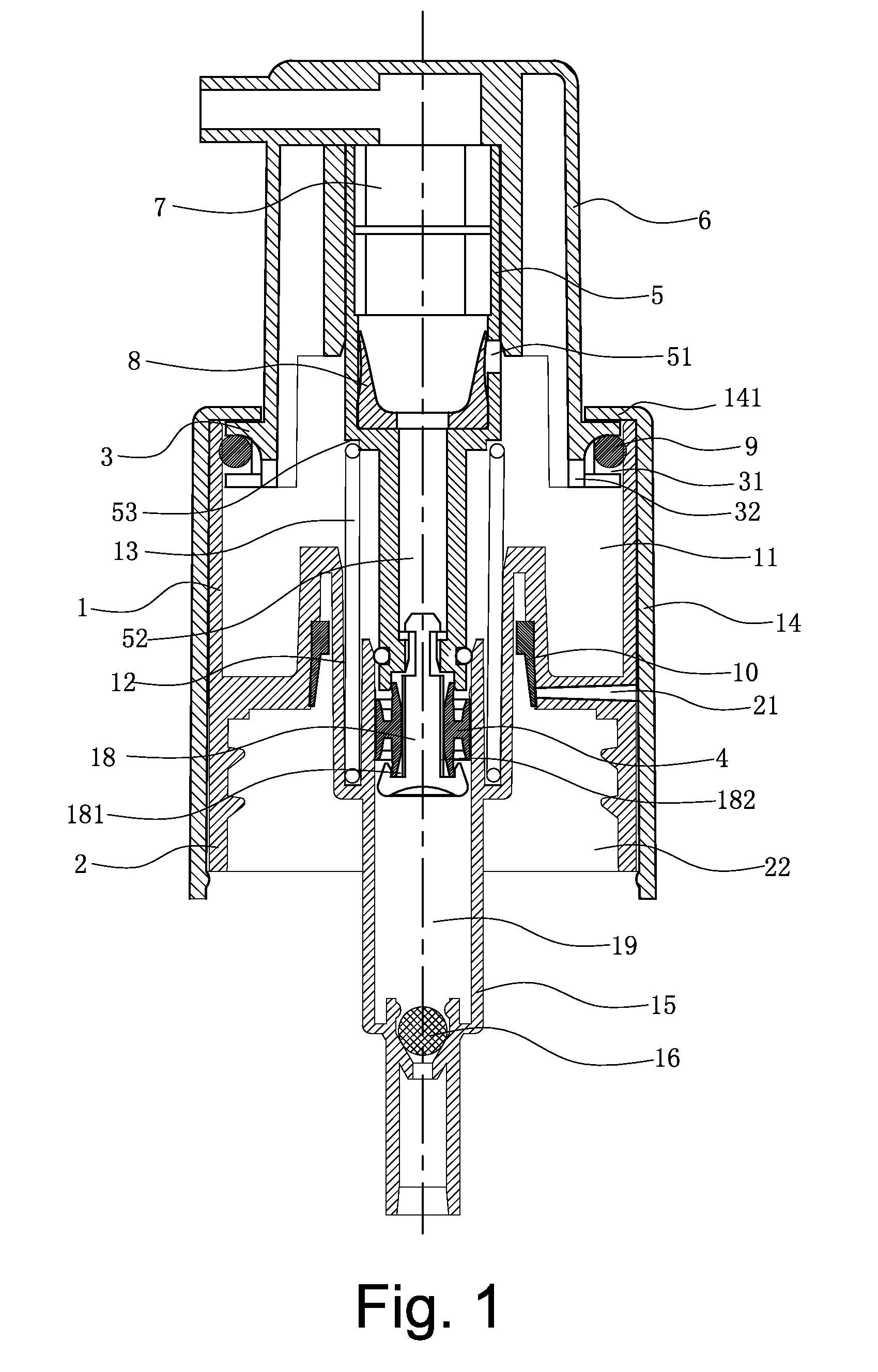

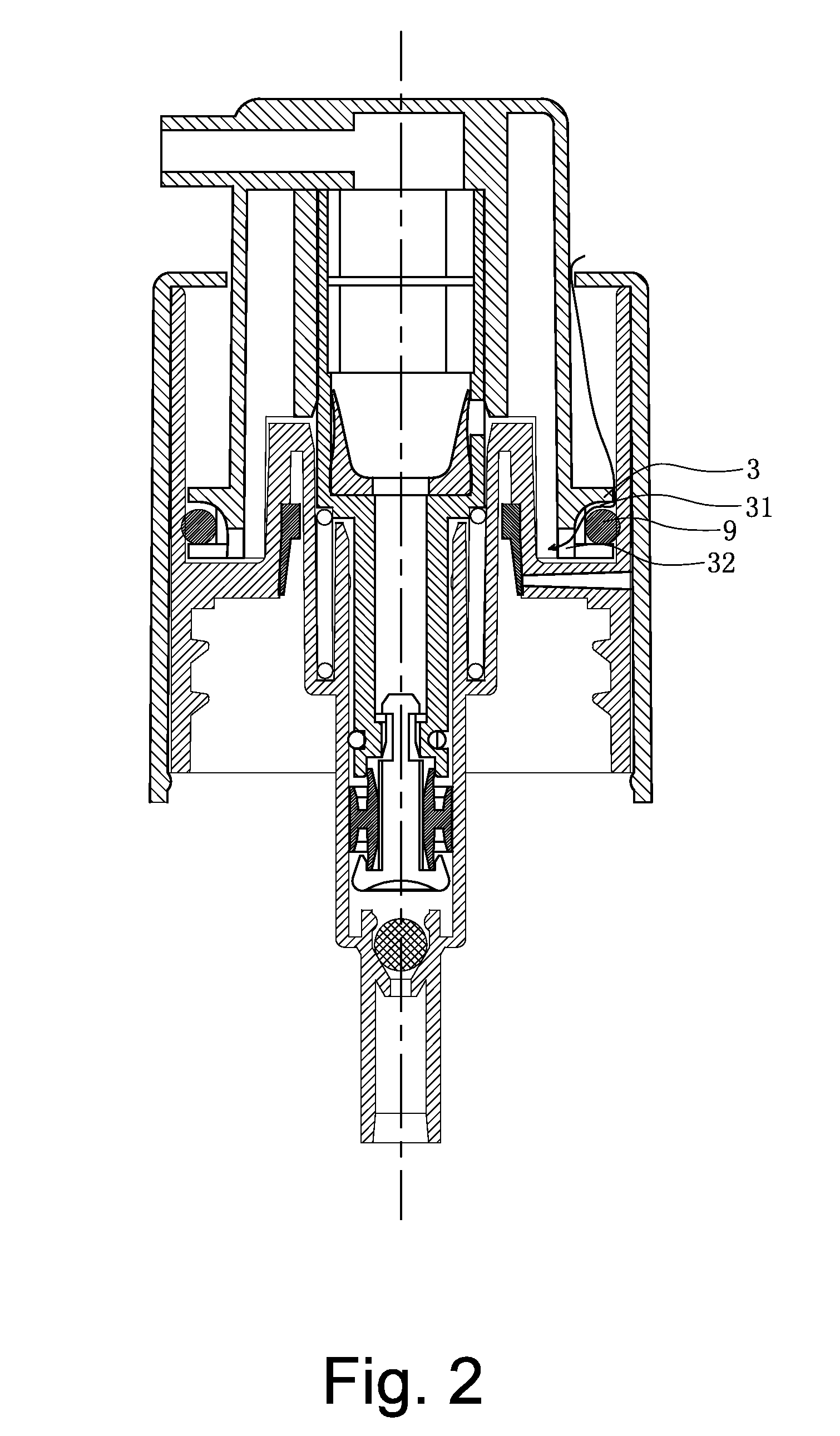

[0015]Detailed description of this invention will now be described with reference to the drawings.

[0016]The embodiment as shown in FIGS. 1-3 is a preferred embodiment of this invention.

[0017]A foam pump, comprising main parts of the pump body 1, big cover 2, big piston 3, small piston 4, piston rod 5, spring 13, head cap 6 and the foam screen 7; said pump body 1 and big cover 2 being formed into a integral structure, the pump body 1 being the upper part, the big cover 2 being the lower part, the upper part being corresponding to the pump body in the former patent, the lower part functions being corresponding to the big cover in the former patent, an inside thread hole 22 with the screw base diameter of 24-25 mm forming on the lower inside wall of said big cover 2, a sucker 15 being provided at the lower part of pump body 1, a steel bead 16 located inside the upper part of said sucker 15 being engaged with a valve base to form an one-way valve.

[0018]The head cap 6 is integrated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com