Mold and method for manufacturing two-layered preforms by injection overmolding, and two-layered preform

a two-layer preform and injection molding technology, which is applied in the direction of turning machine accessories, drawing profiling tools, pipes, etc., can solve the problems of affecting the quality of the preform, so as to reduce the capacity of the inner layer and achieve the effect of efficient barrier against ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

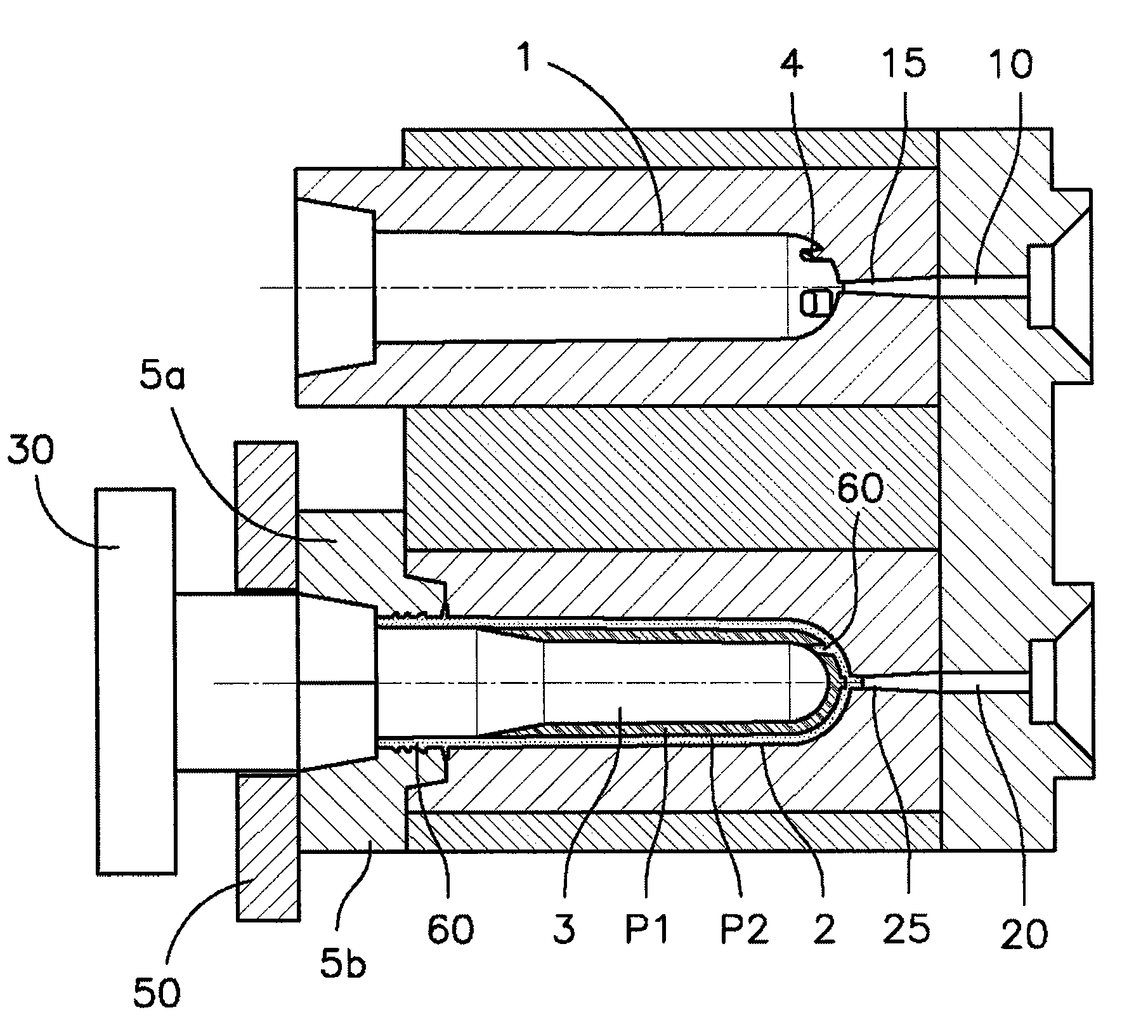

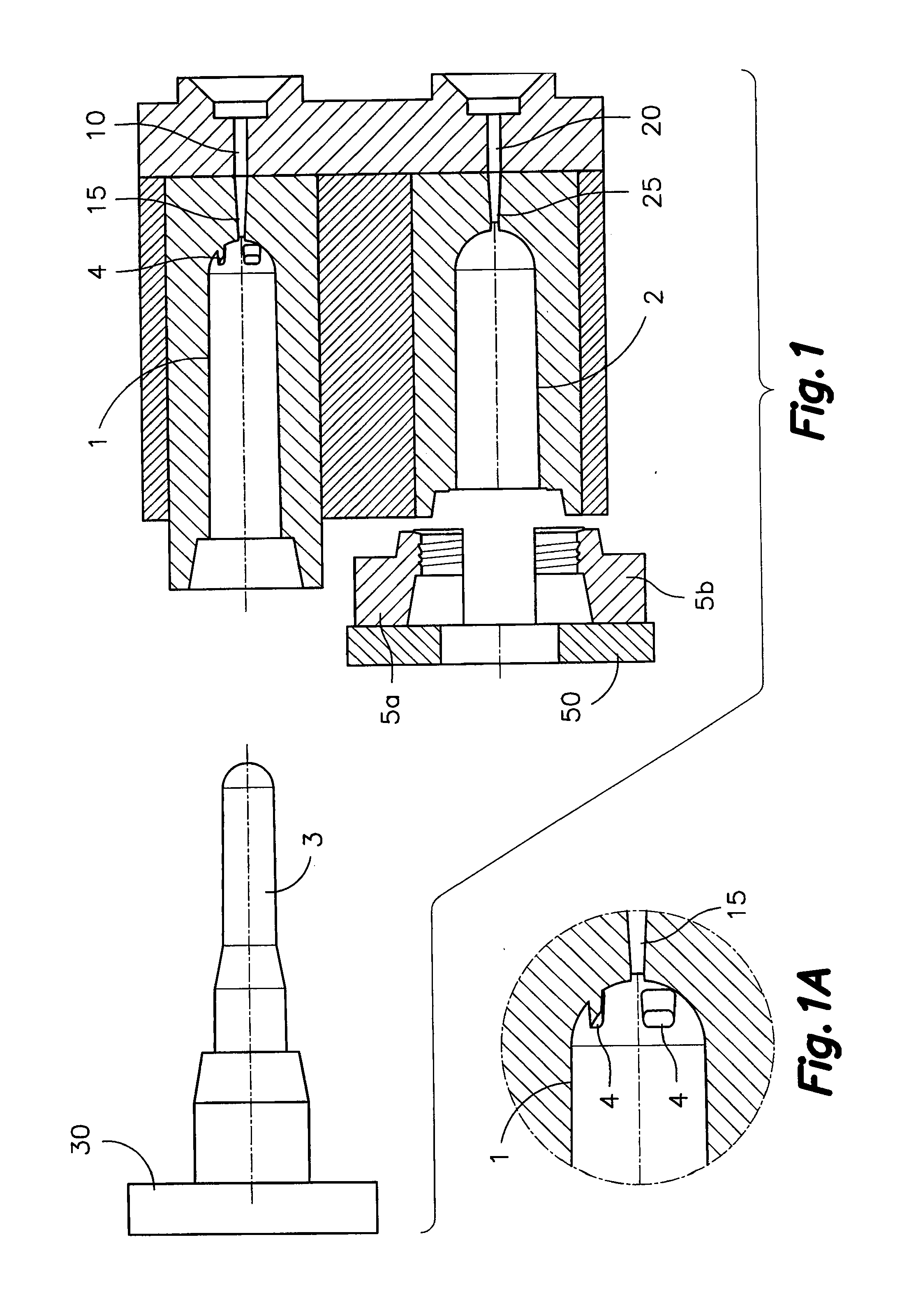

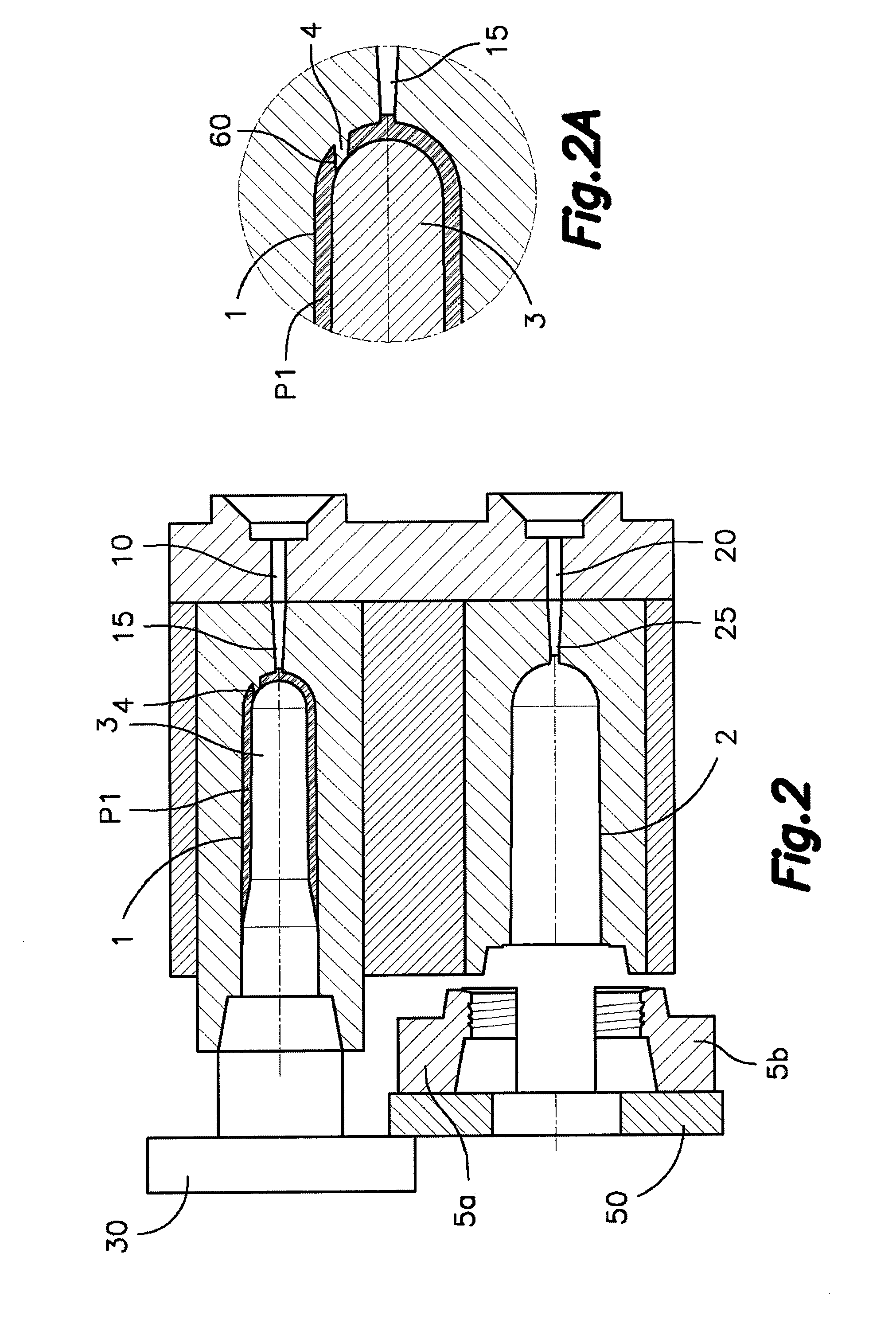

[0044]Referring first to FIG. 1, there are shown the different parts forming a mold for manufacturing two-layered preforms by injection overmolding according to the mold and / or the method of the present invention. The mold comprises a primary molding cavity 1, which is connected to a first hot channel 10 for supplying a primary molding material into said primary molding cavity 1 through a first injection nozzle 15, and an overmolding cavity 2 connected to a second hot channel 20 for supplying an overmolding material into said overmolding cavity 2 through a second injection nozzle 25. In the embodiment shown, the primary molding cavity 1 and overmolding cavity 2 are stationary, although this is not essential for the present invention. The mold further comprises a core 3 connected to a mobile plate 30 of an injection molding apparatus (not shown) operated to alternately introduce said core 3 into the primary molding cavity 1 and into the overmolding cavity 2. In the embodiment shown i...

second embodiment

[0064]FIG. 14 shows another example of two-layered preform P which can be produced by means of the mold and / or the method of the present invention. The two-layered preform P of FIG. 14 is a preform with a very thin wall, for example of less than 2.1 mm. The first layer P1 provides a single layer for most of the wall of the preform, optionally including a neck (not shown) at the open end. This first layer P1 has a thickness equal to or less than 2.1 mm. The second layer P2 is very small and only covers the region corresponding to the closed bottom of the first layer P1, with the bulges 65 of the second layer P2 covering but not filling the openings 60 left by the supporting members 4. It must be indicated that it is not necessary for the second layer P2 to cover all the closed bottom of the preform with a thickness substantially equivalent to the thickness of the first layer P1. The overmolding cavity 2 can alternatively be configured to form the second layer P2 with a much smaller t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com