External breast prosthesis

a breast prosthesis and external technology, applied in the field of breast prosthesis, can solve the problems of limited functionality and performance, lack of elasticity, and general lack of prosthesis consistency, and achieve the effect of improving skin and other features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

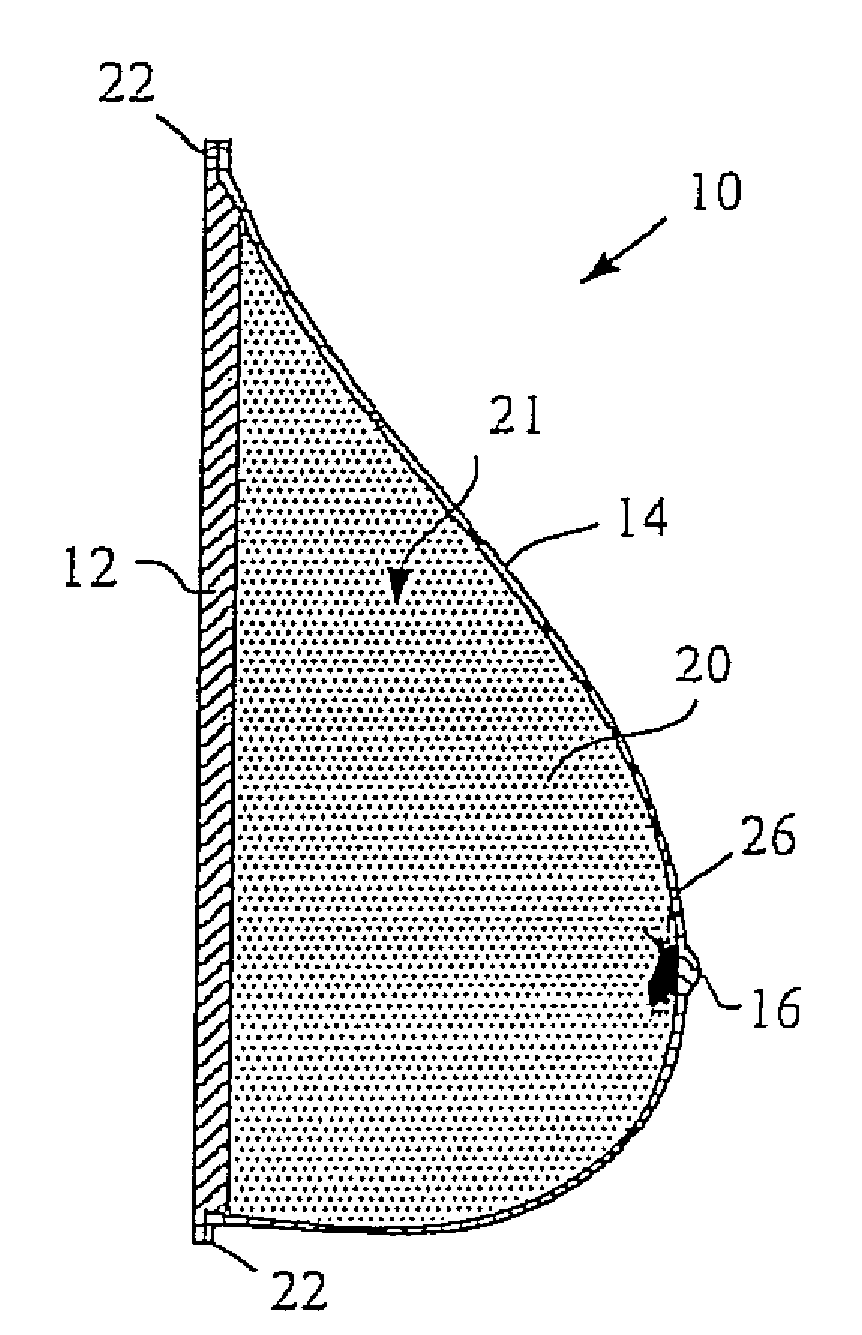

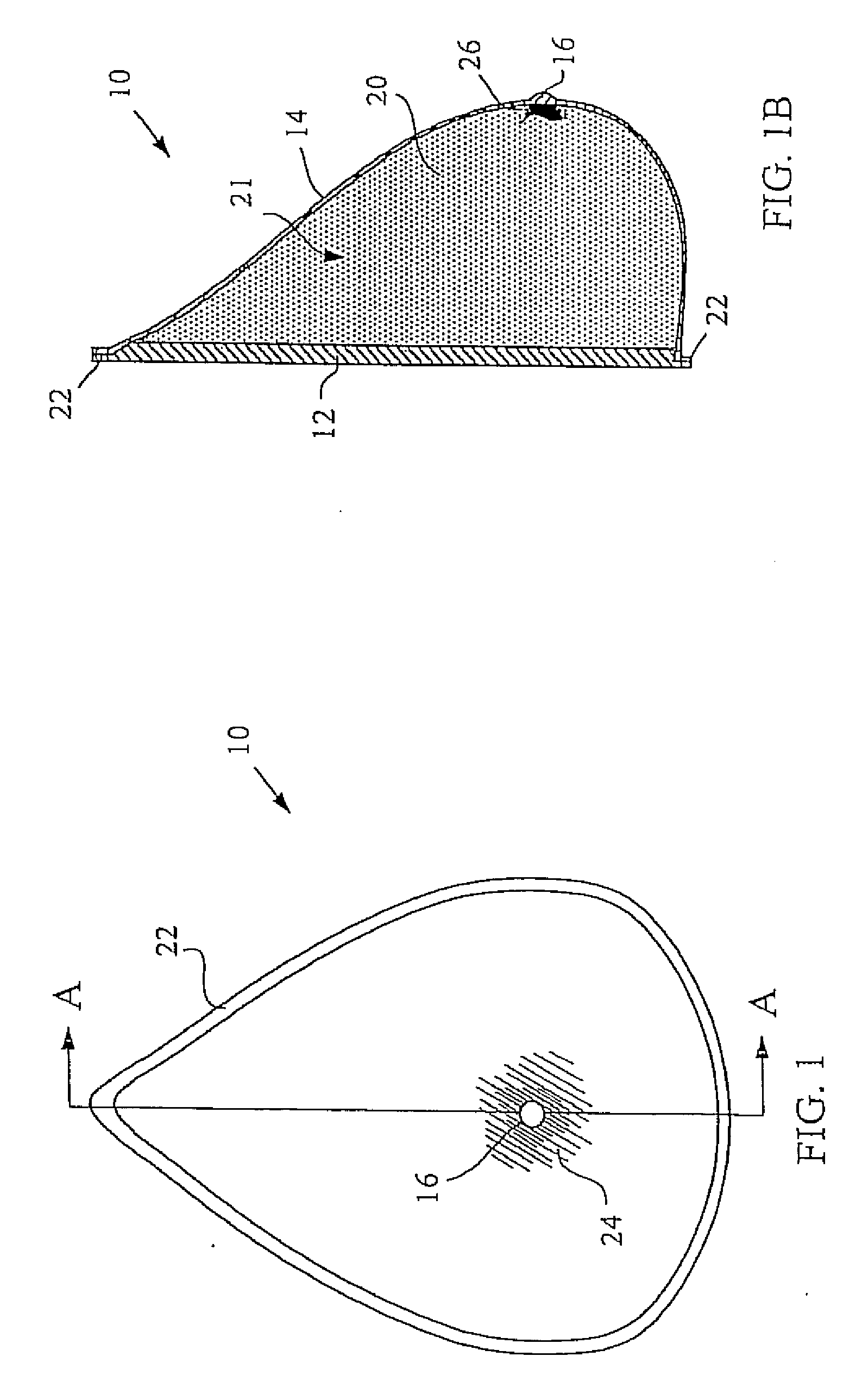

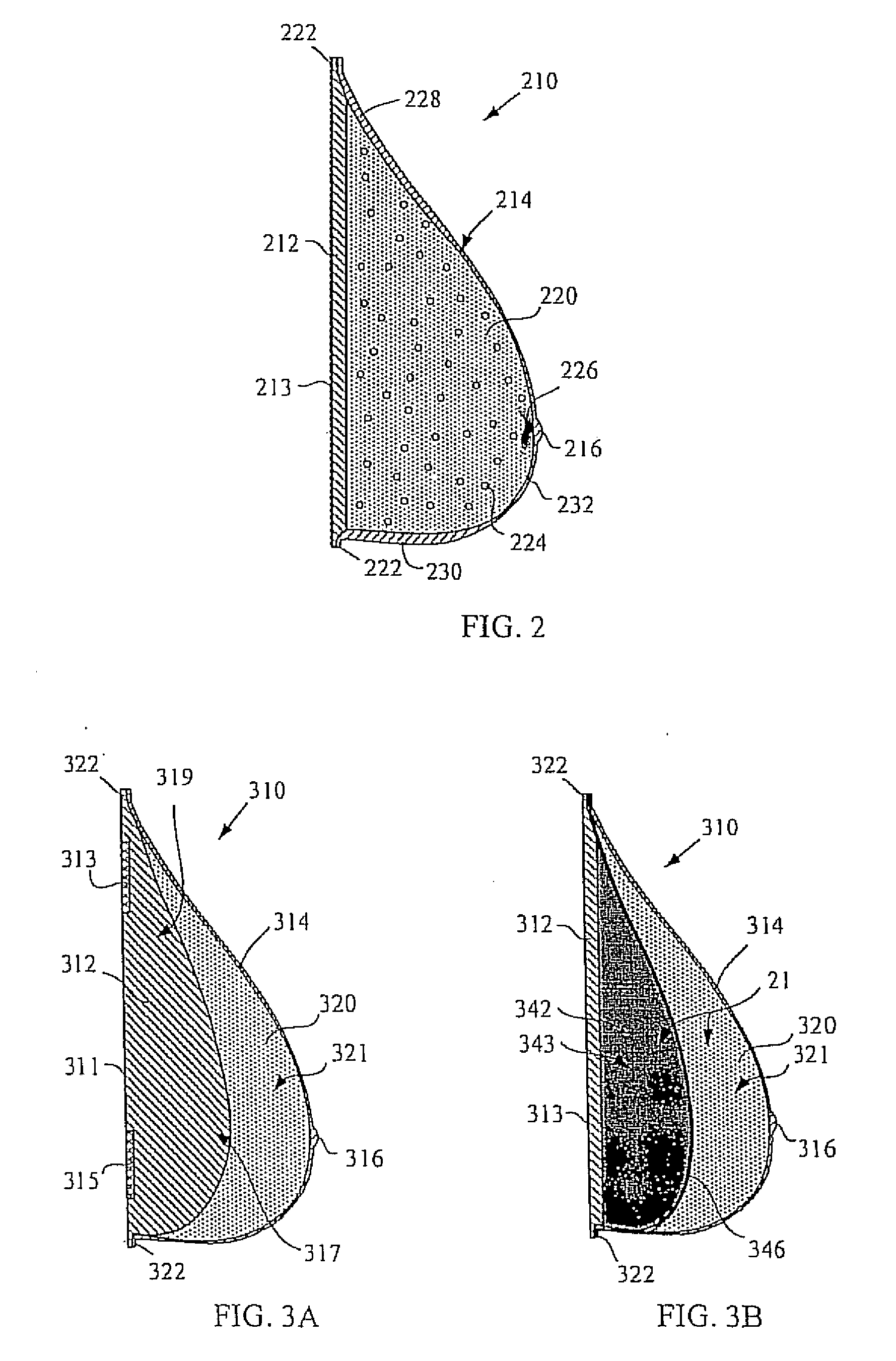

[0096]In a particular example, an external breast prosthesis according to an embodiment of the present invention was made that has front and rear skins comprising a mixture of styrenic block copolymer (SEPTON® 4055, a SEEPS) at 100 pph, an additive (IRGANOX® 1010, a pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate)) at 2.9 to 3.85 pph, and plasticizing oil (CARNATION® 70) at 500 to 700 pph. The mixture was heated in an injection molding screw to 385-410.degree. F., injected into a cool mold (85-1 10.degree. F.), and cured for 60 to 100 seconds. In this example, front and rear skins were molded separately, and then bonded together to form a perimeter seal using an adhesive as described above with respect to FIG. 5. One skilled in the art will appreciate that other methods of joining or sealing the skins may be used, or the front and rear skins could have been formed in the same mold as a contiguous skin.

[0097]In this example, front skin was molded in the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com