PROCESS AND APPARATUS FOR PRODUCING A REFORMATE BY INTRODUCING n-BUTANE

a technology of reformate and apparatus, which is applied in the direction of catalytic naphtha reforming, naphtha reforming, and thermal naphtha reforming, etc., can solve the problems of reducing the yield of aromatics, reducing the yield of undesirable products, and failing to identify specific components, so as to reduce the production of c3, increase the total aromatic yield, and reduce the vapor pressure of a gasoline product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0030]The following examples are intended to further illustrate the disclosed embodiments. These illustrations of the embodiments are not meant to limit the claims to the particular details of these examples. These examples can be based on engineering calculations and actual operating experience with similar processes.

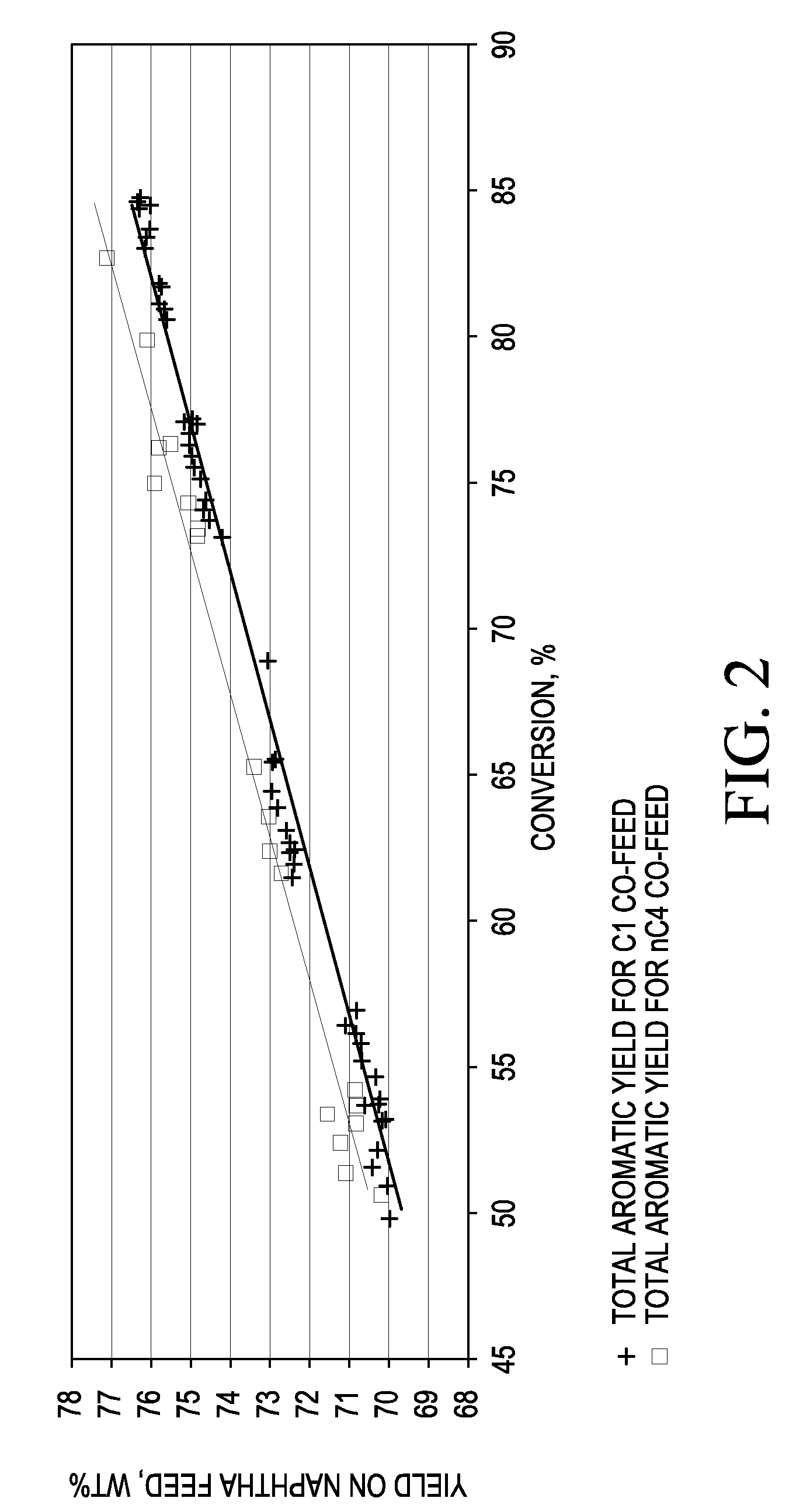

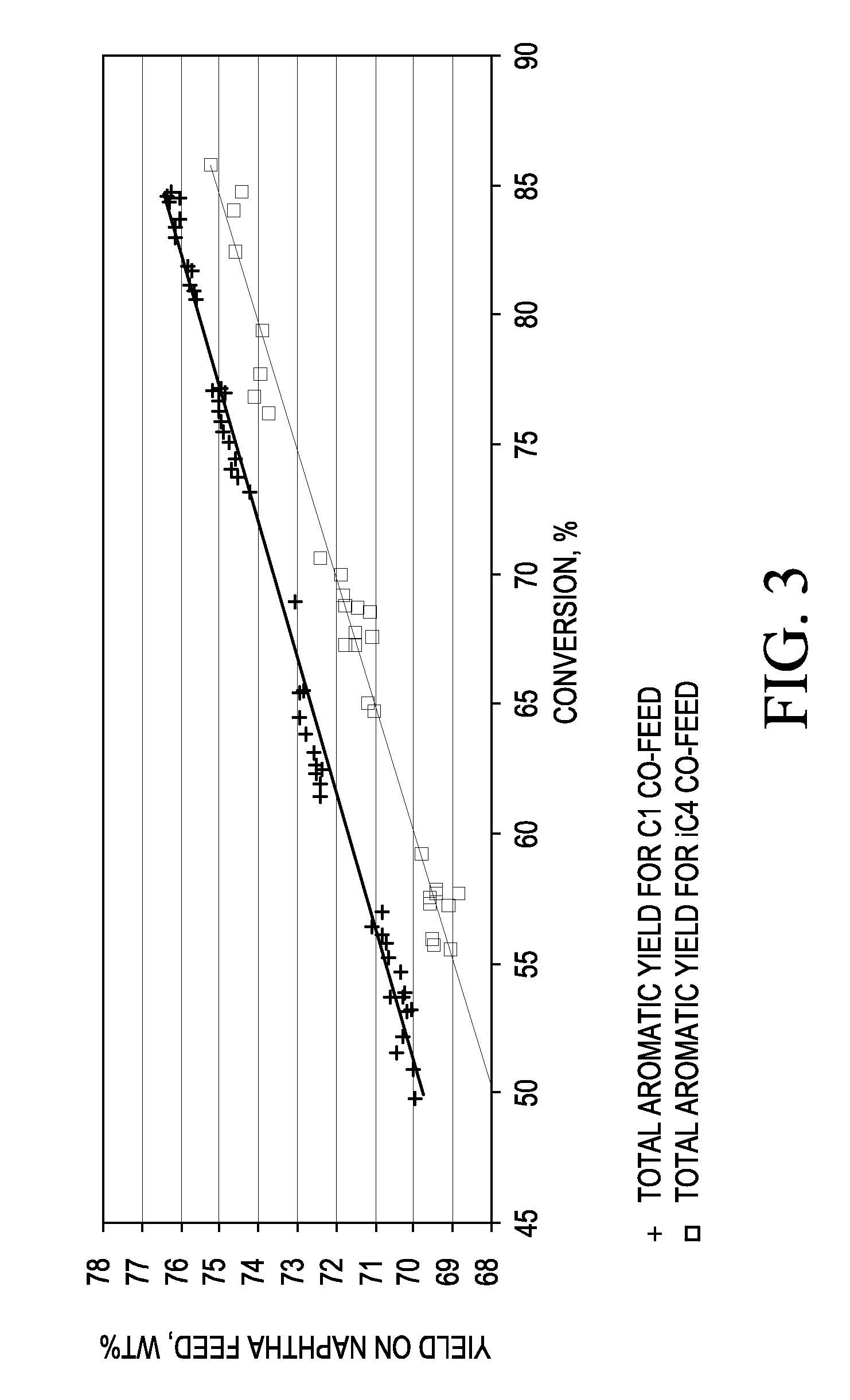

[0031]Tests are conducted by comparing a co-feed of methane (C1) and naphtha, a co-feed of normal butane or n-butane (nC4) and naphtha, and a co-feed of isobutane (iC4) and naphtha, which may be referred to as a co-feed of, respectively, methane, n-butane, and isobutane. Each test is conducted in a pilot plant using the same reforming catalyst made in accordance with US 2006 / 0102520 A1. The pilot plant is operated to minimize catalyst de-activation during the test. The catalyst has a chloride content of about 1% by weight. The feedstock is a commercial naphtha with an endpoint of 160° C. The methane, n-butane, and isobutane are provided as pure components. The feed con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com