Manufacturing apparatus and method for producing a preform

a manufacturing apparatus and preform technology, applied in the direction of turning machines, turning machine accessories, drawing profiling tools, etc., can solve the problems of weak joint types, unlikely to be formed in an automation process, and material used for the production of preforms that does not meet the strength requirements for the final preform, etc., to reduce production time, reduce discontinuities, and improve efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

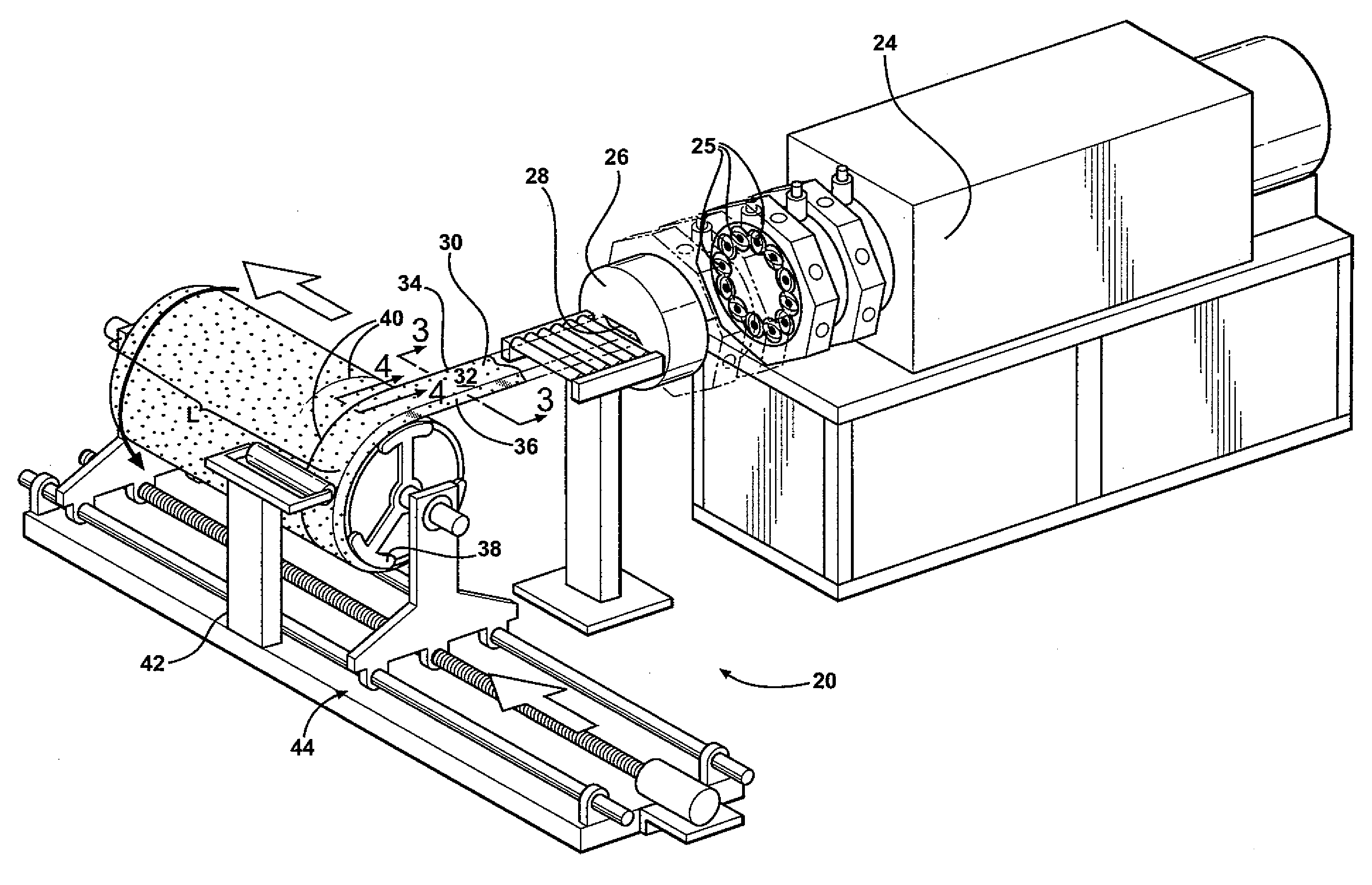

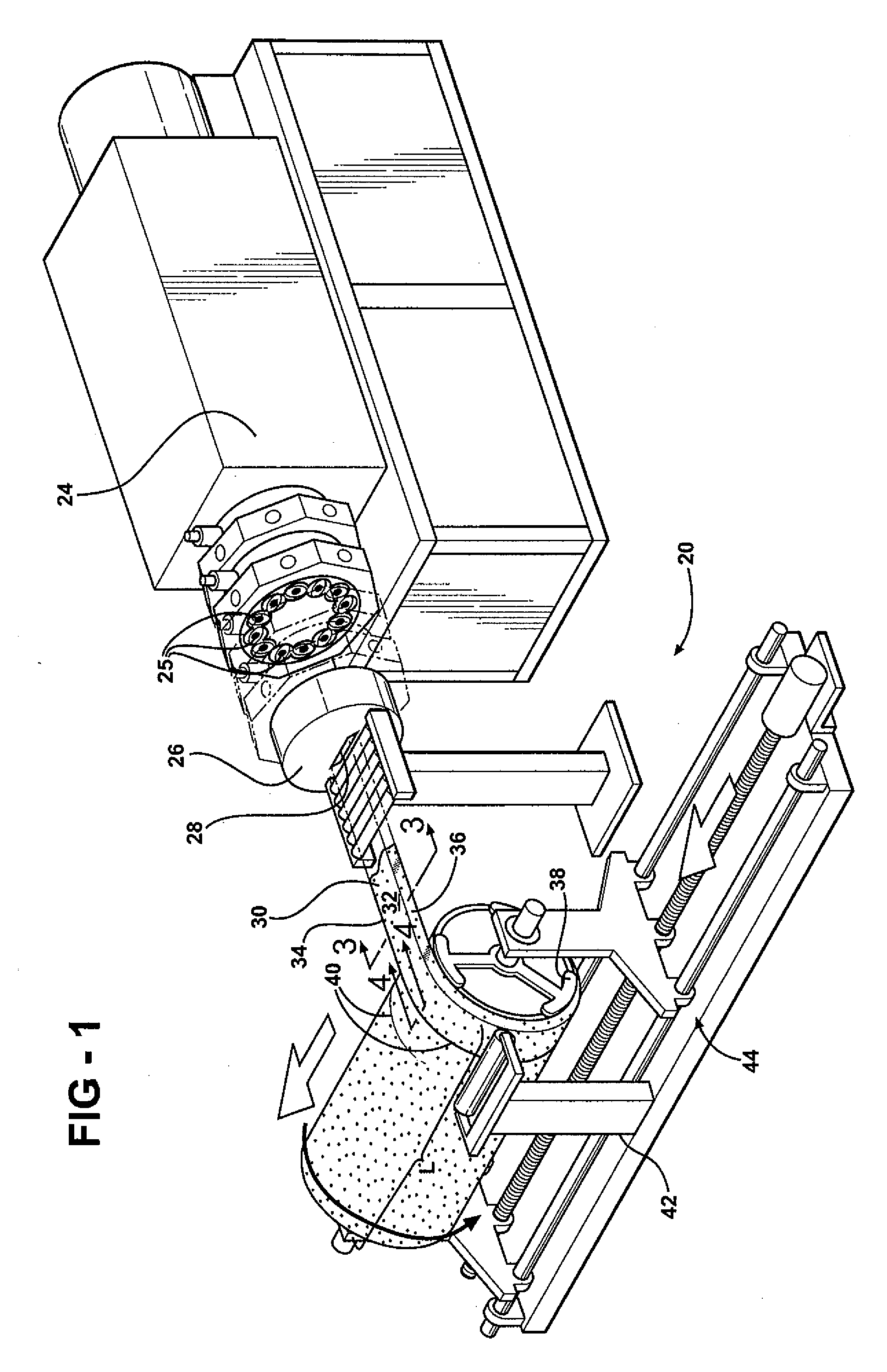

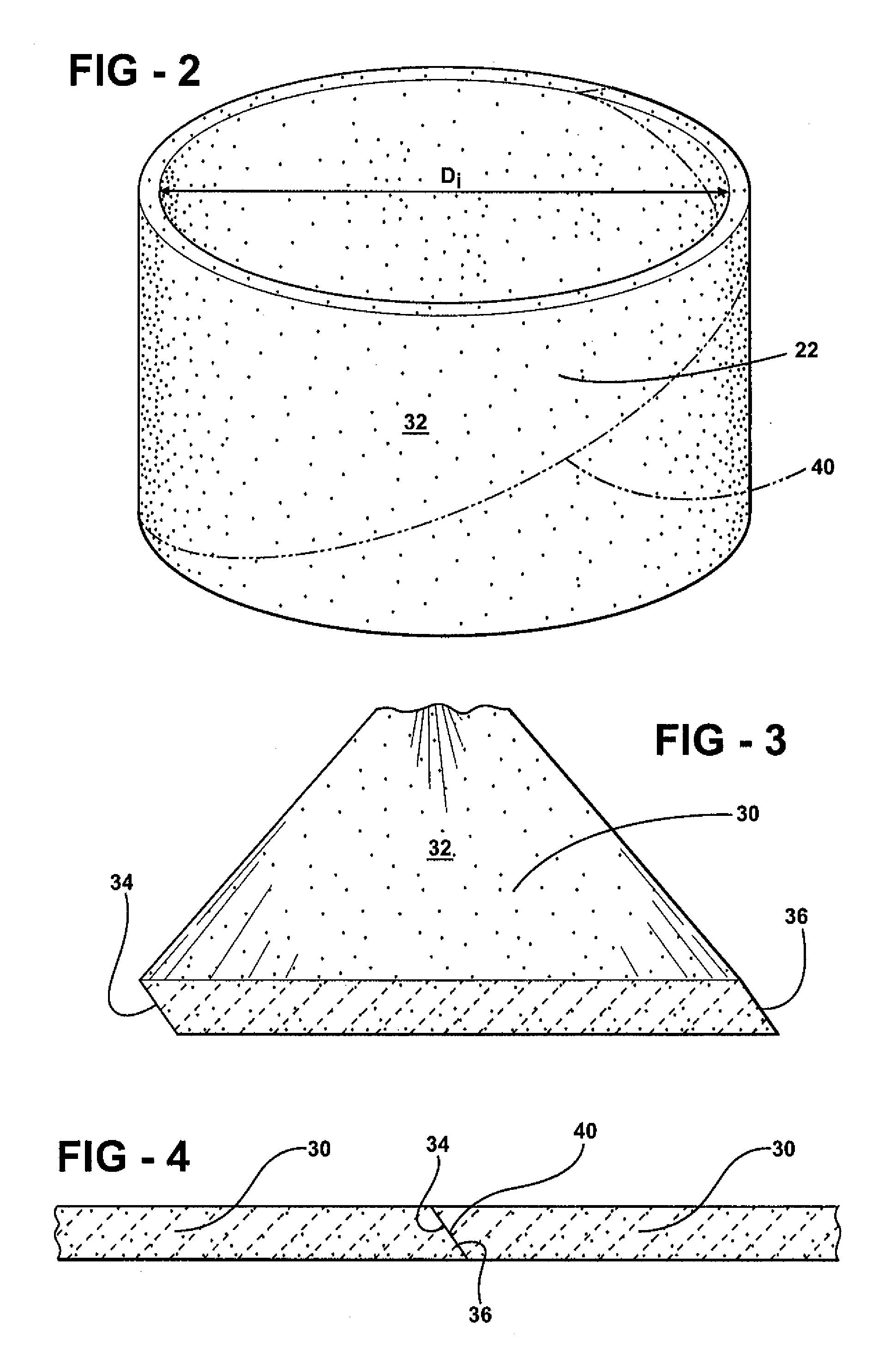

[0019]Referring to the Figures, wherein like numerals indicate like or corresponding parts throughout the several views, a manufacturing apparatus 20 for producing a ceramic article or preform 22 from a material (not shown) is generally shown in FIG. 1. The preform 22 has a width and a final configuration defining an internal diameter Di as shown in FIG. 2.

[0020]The manufacturing apparatus 20 includes a multi-screw extruder 24 for processing the material and producing an extrudate 30. The material preferably includes ceramic particles and ceramic fibers with an aspect ratio of greater than 3:1 with the ceramic fibers being substantially randomly orientated in three dimensions. However, it is to be appreciated that the material can be manufactured from components other than ceramic particles and ceramic fibers without deviating from the broadest scope of the subject invention.

[0021]The multi-screw extruder 24 preferably has at least three intermeshing screws 25. The at least three in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angular velocity | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com