Evaluating multiphase fluid flow in a wellbore using temperature and pressure measurements

a multi-phase fluid flow and temperature and pressure measurement technology, applied in the field of oil or gas well fluid flow evaluation, can solve the problem that the known art does not provide a solution to obtain continuous or real-time quantitative measurements and evaluations, and achieve the effect of reliable, accurate and continuous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

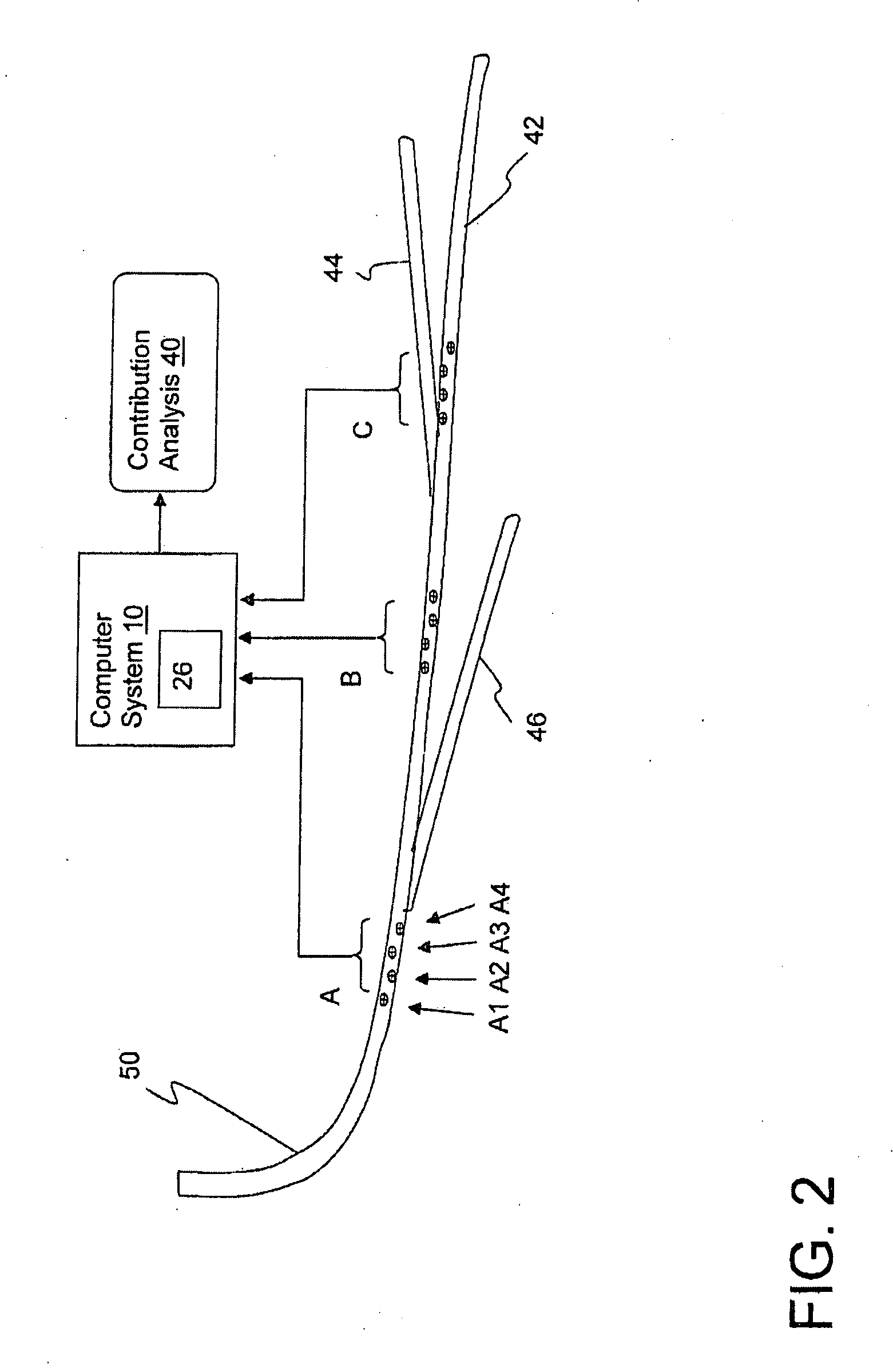

[0017]Referring to the drawings, FIG. 1 depicts an overview of an illustrative system 11 for implementing aspects of the present invention. As shown, a computer system 10 is provided that includes a multiphase flow analysis system 18 for analyzing fluid characteristics flowing through a wellbore 34. Also provided are at least two sensors 30, 32 placed within the wellbore to provide multipoint pressure and temperature readings.

[0018]Multiphase flow analysis system 18 includes a pressure and temperature input system 20 for obtaining pressure and temperature readings from each sensor 30, 32 in a continuous, as needed, or periodic manner. Also included is a computation system 22 that utilizes a flow analysis model 24 for computing wellbore fluid properties, including one or more of: (1) the fluid mixture; (2) phase velocities; (3) flow rates; (4) mixture density; (5) mixture viscosity; (6) fluid holdups; and (7) estimates of the slip velocities between the wellbore liquid and gas phases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com