Impact Absorbing Frame and Layered Structure System for Safety Helmets

a safety helmet and frame technology, applied in the field of protective headgear, can solve the problems of inability to provide protection against both high and low degrees of impact, increased head and neck force, and inability to meet the needs of protection, so as to avoid the increased risk of injury, enhance the inherent protection, and uniquely minimize the most common and destructive ‘contre coup’ injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

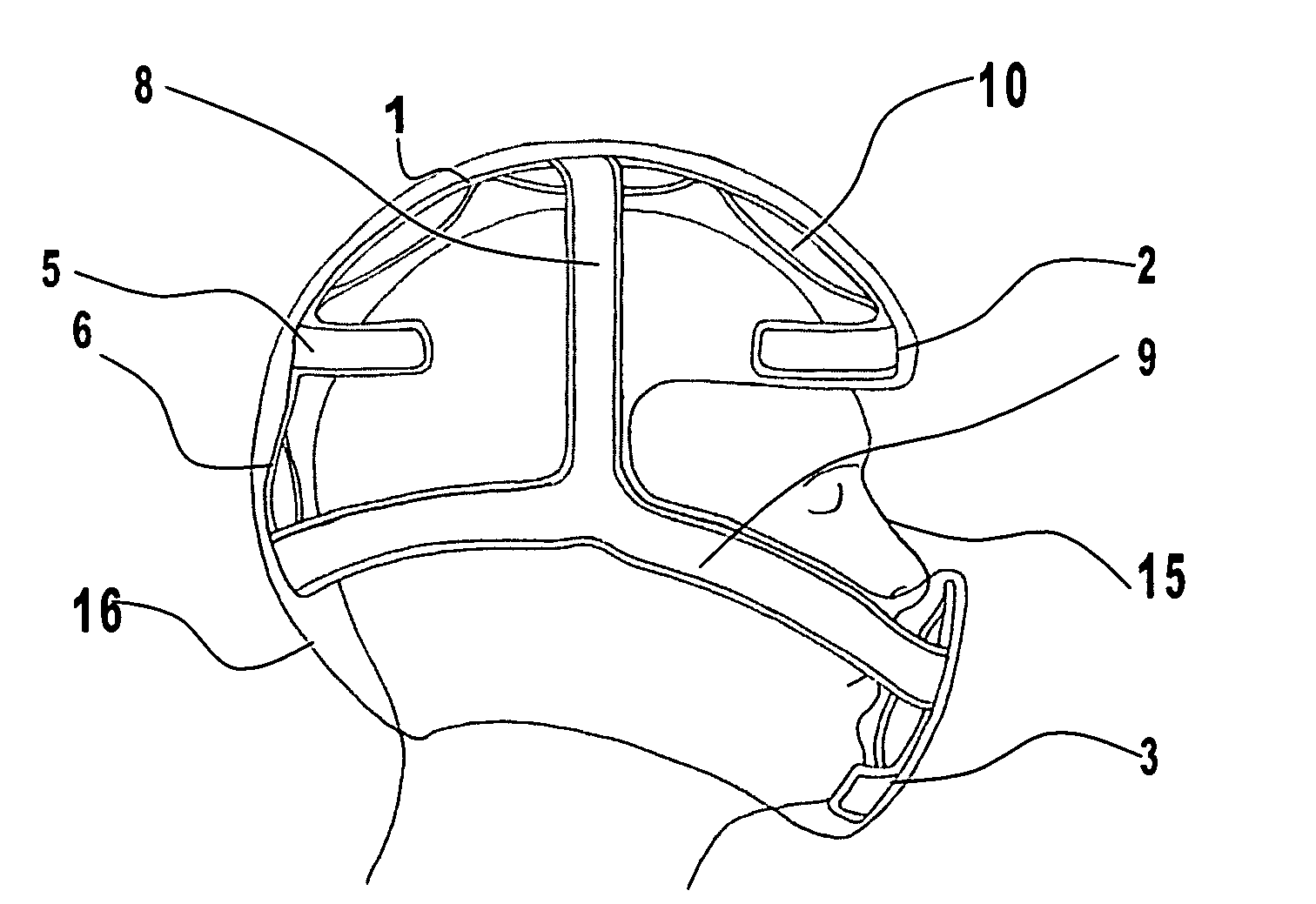

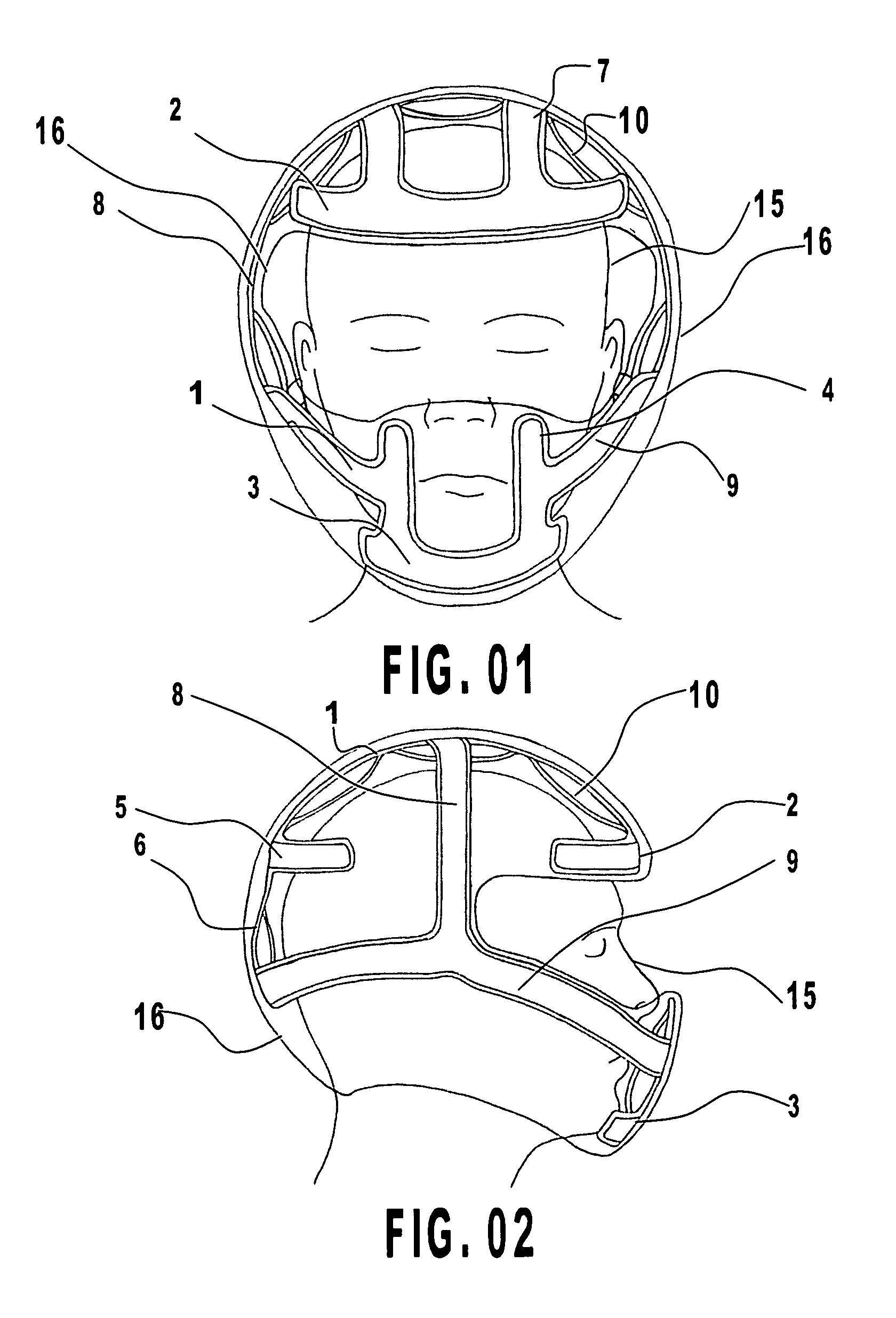

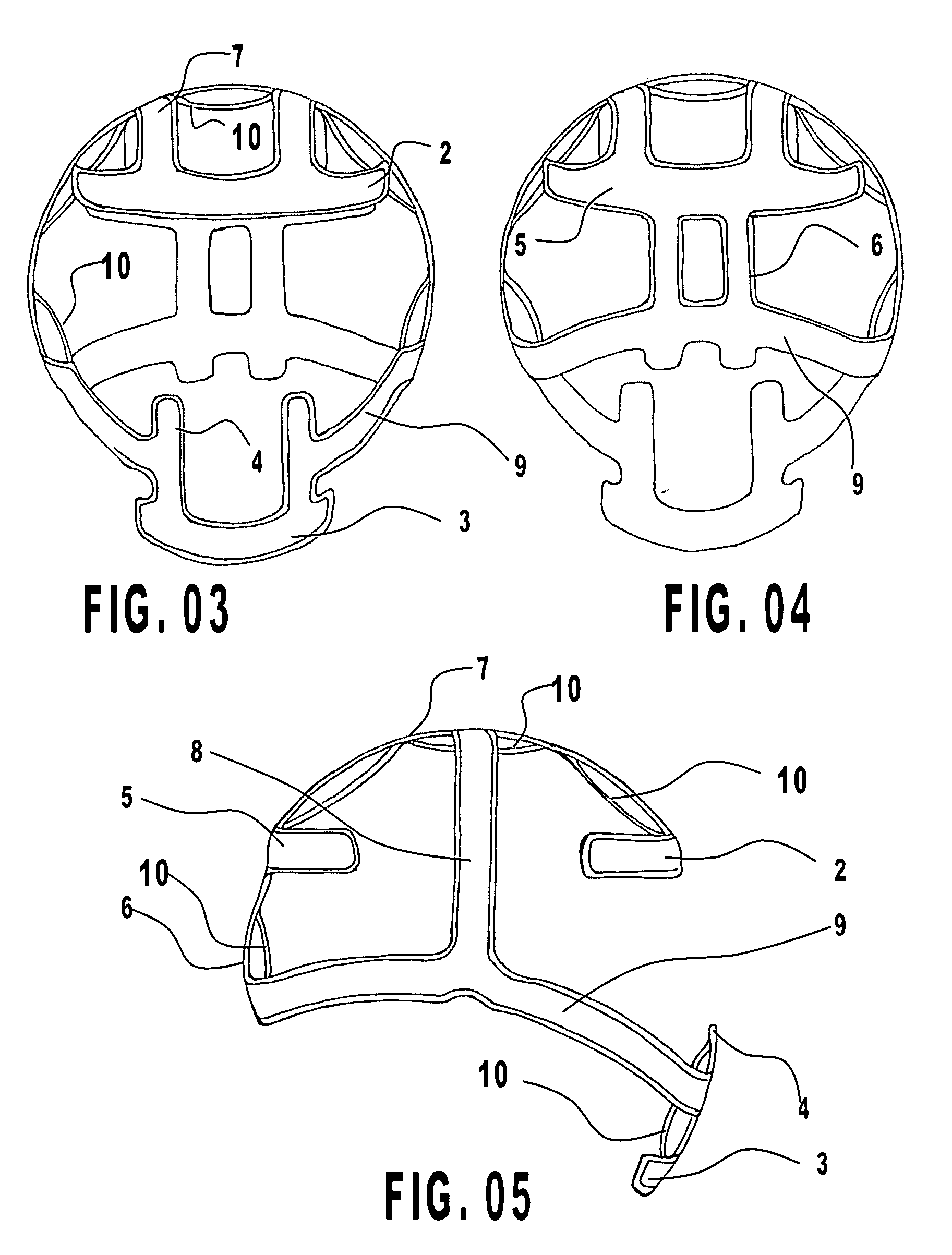

[0044]Referring now to the drawings wherein like or corresponding reference numerals are used for like or corresponding parts throughout the several views. The present invention incorporates a frame 1, herein referred to as “frame”, This frame is firmly attached and encapsulated on the entirety of its surface by an energy-absorbing structure No's 11, 12, 13 and 14, herein referred to as “structure”FIG. 09. Said assembly herein collectively referred to as “system” or “Impact Absorbing Frame and Layered Structure System for Safety Helmets.” The system may be manufactured as an integrated, standalone protective layer that could be universally adapted and incorporated onto any modifiable safety helmet shell design shaped to correspond with the system and the user's head. The following examples illustrate the benefits of such a multi-layered protective system.

[0045]A strong yet flexible helmet shell 16 would be the first protective layer. This layer increases the impact time (duration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com