Apparatus and method

a technology of tubing and handling apparatus, which is applied in the direction of fluid removal, projectors, cameras, etc., can solve the problems of tubing bending or sag, the relationship between the deck space required and the arrangement, and the tubing may tend to bend or sag., so as to reduce the fatigue on the tubing and avoid plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

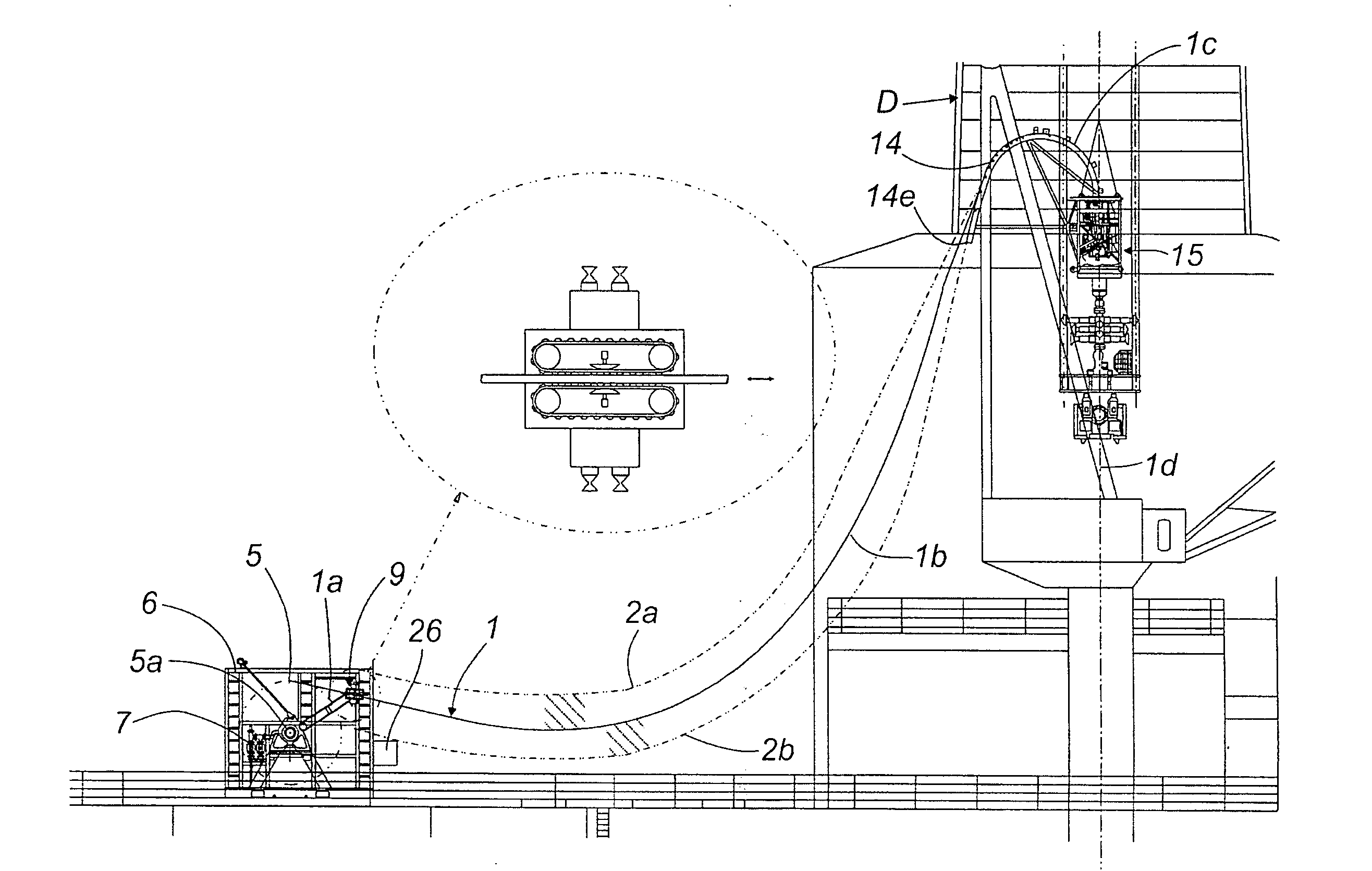

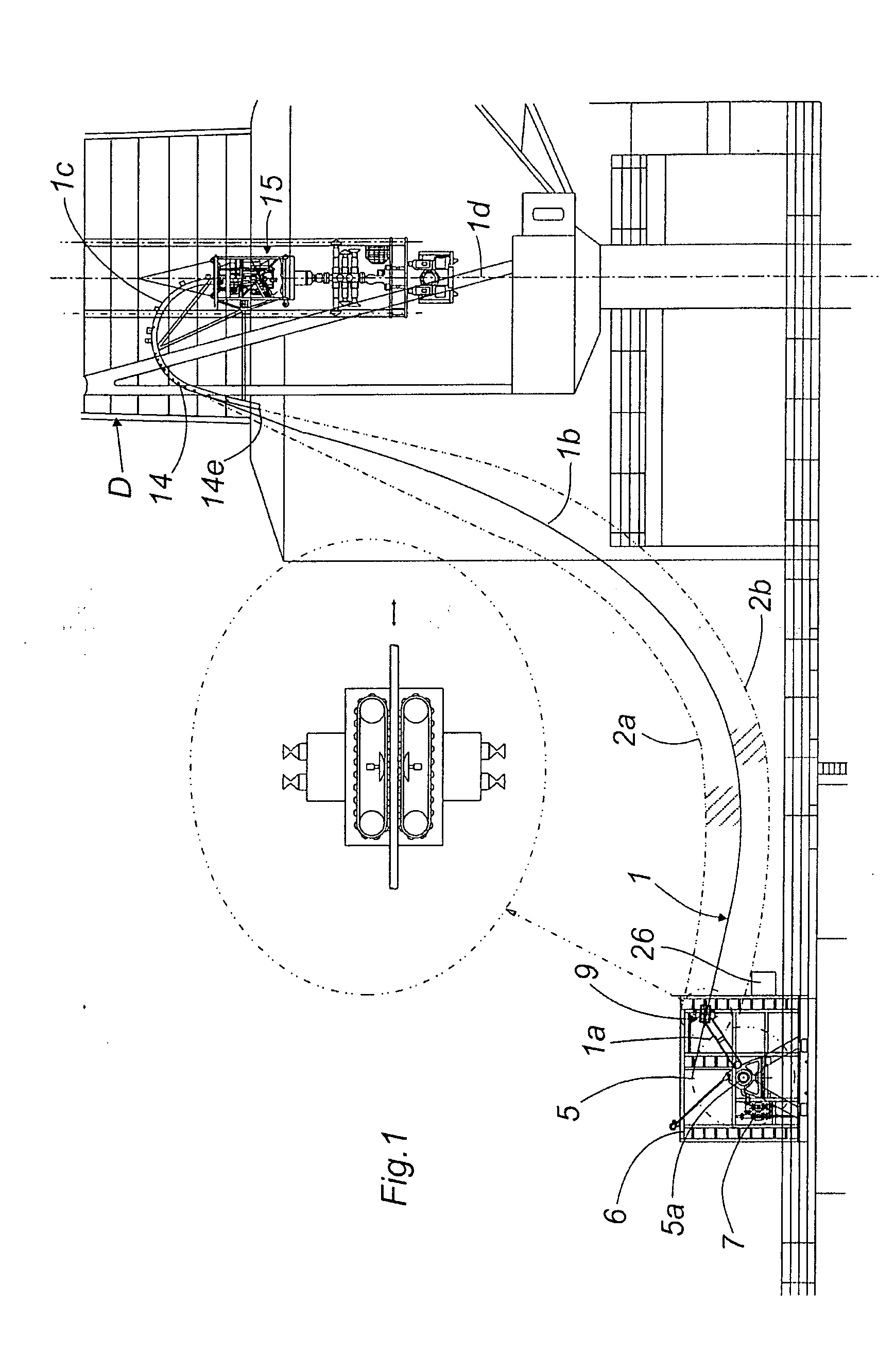

[0060]Referring now to the drawings, FIG. 1 shows a tubing handling system for injecting coiled tubing into an oil or gas well. The system has a reel 5 of tubing 1, rotatably mounted on its axis 5a on bearings in a frame 6. The reel is cylindrical and is driven in rotation around the bearings by a motor 7. The tubing 1 is spooled on and off the reel by a levelwind head 9. The levelwind head 9 has a pair of sheaves on each end that engage respective rails 8 extending parallel to the axis of rotation of the reel 5. The levelwind head 9 can move along the rails 8 parallel to the axis of the reel, to guide the tubing and distribute it onto and from the reel in an even manner. The lateral motion of the levelwind head along the rails 8 can be powered or free.

[0061]The reel 5 is mounted on the deck of a drilling platform, over an oil or gas well. The platform has a derrick injector head 15 of known design which is suspended from the derrick D. The derrick injector head 15 controls the rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com