Decurling mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first example embodiment

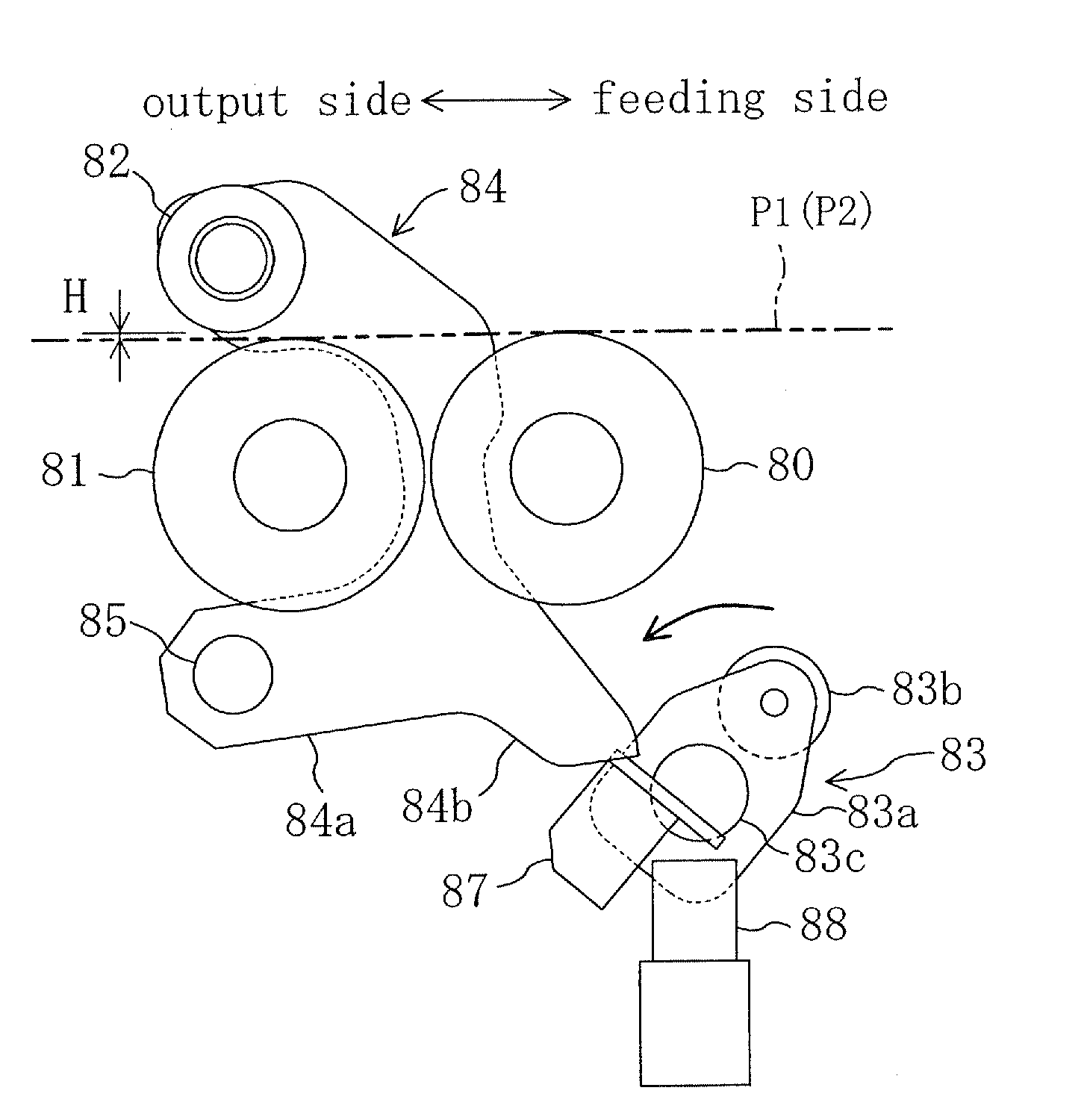

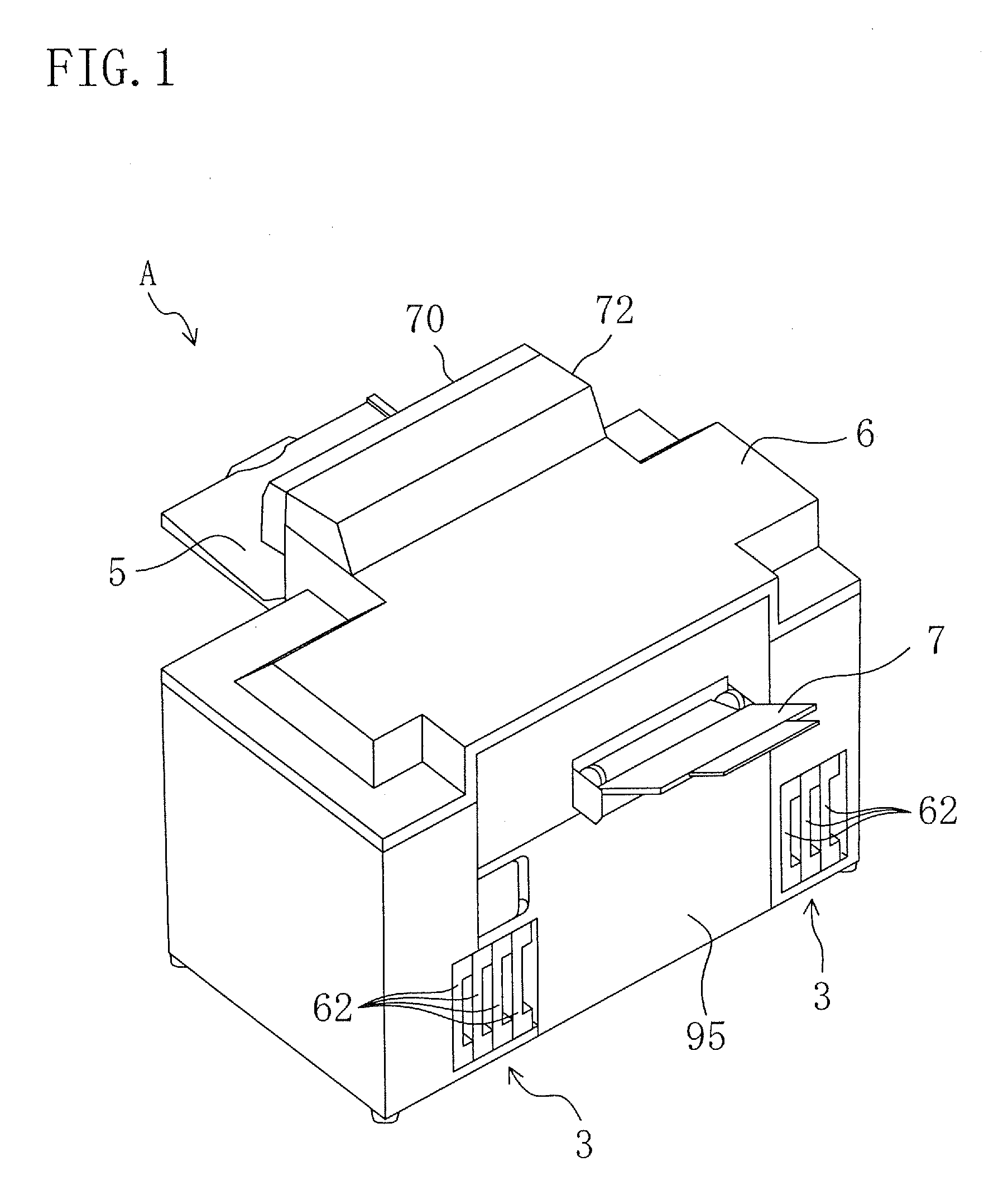

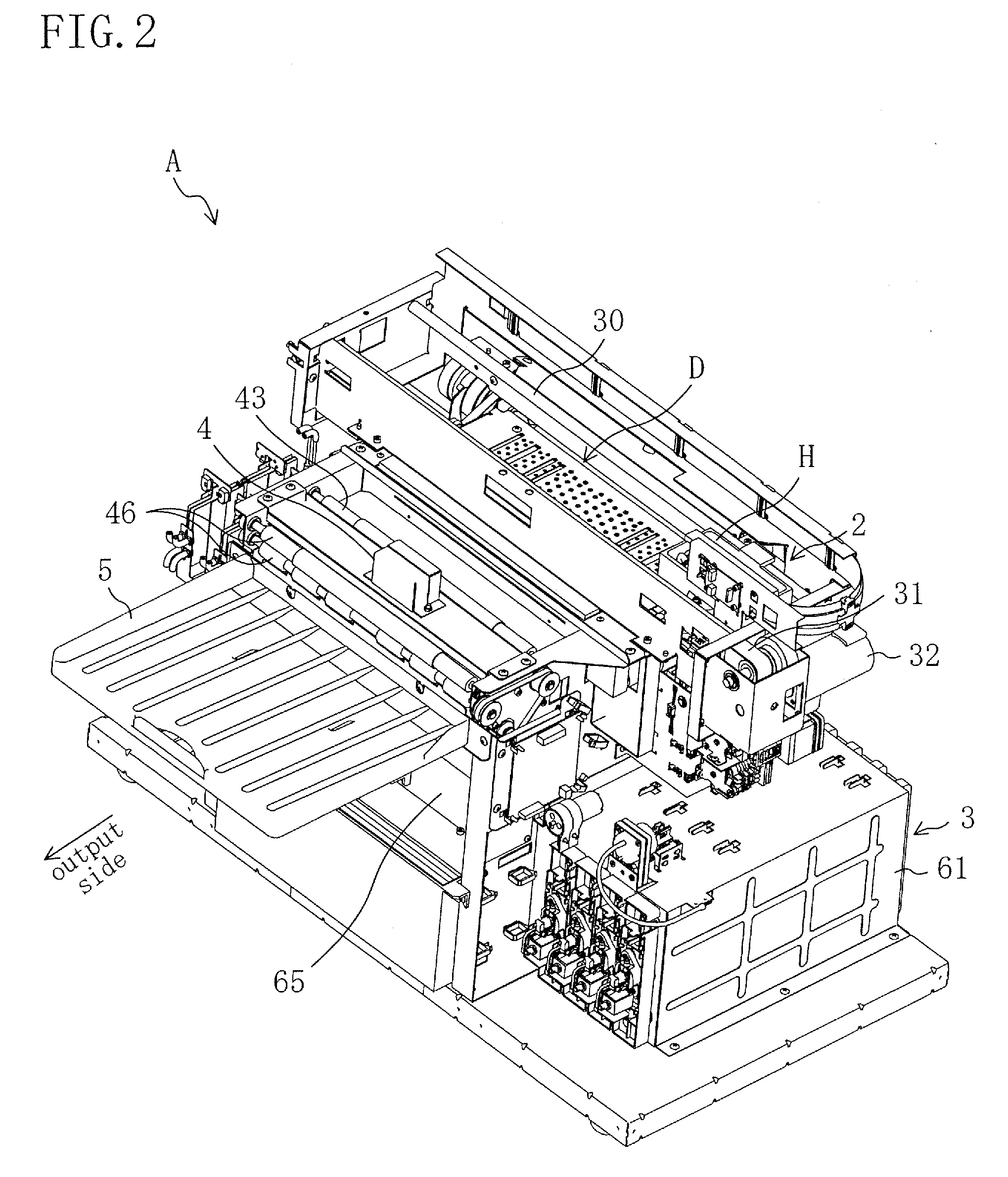

[0034]FIG. 1 shows the appearance of an inkjet printer A including a decurling unit as a decurling mechanism according to a first example embodiment, and FIGS. 2 to 5 show the internal structure of the inkjet printer A. The inkjet printer A is used for a photographic printing system and, for example, used for printing photographic images on printing paper P1 or P2 based on image data transmitted via a communication cable from a reception block for obtaining the image data and correcting it as necessary. More specifically, the inkjet printer A is configured to be capable of performing an automatic printing for pulling out one end of a long roll of printing paper P2 and printing an image on the printing surface of the roll of printing paper P2 (hereinafter, referred to as a paper web P2) and a manual-feed printing for printing an image on the printing surface of a sheet of printing paper P1 (hereinafter, referred to as a paper sheet P1) previously cut in a given size.

[0035]When in the...

second example embodiment

[0094]FIG. 12 is a perspective view showing the structure of an inkjet printer according to a second example embodiment. This example embodiment is different from the first example embodiment in that a conveyance unit 100 and an collection unit 110 are provided instead of the paper output tray 5. Therefore, the same parts are identified by the same reference numerals as in the first example embodiment and a description is given only of different points.

[0095]As shown in FIGS. 12 and 13, the inkjet printer A includes a printer body 90, a conveyance unit 100 disposed downstream of the printer body 90, and a collection unit 110 disposed downstream of the conveyance unit 100 in the direction of paper conveyance. The printer body 90 has substantially the same structure as described in the first example embodiment and, therefore, a description thereof is not given.

[0096]The conveyance unit 100 constitutes a paper placement part for receiving pieces of printing paper P1 or P2 output throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com