Flat packing suitcase system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

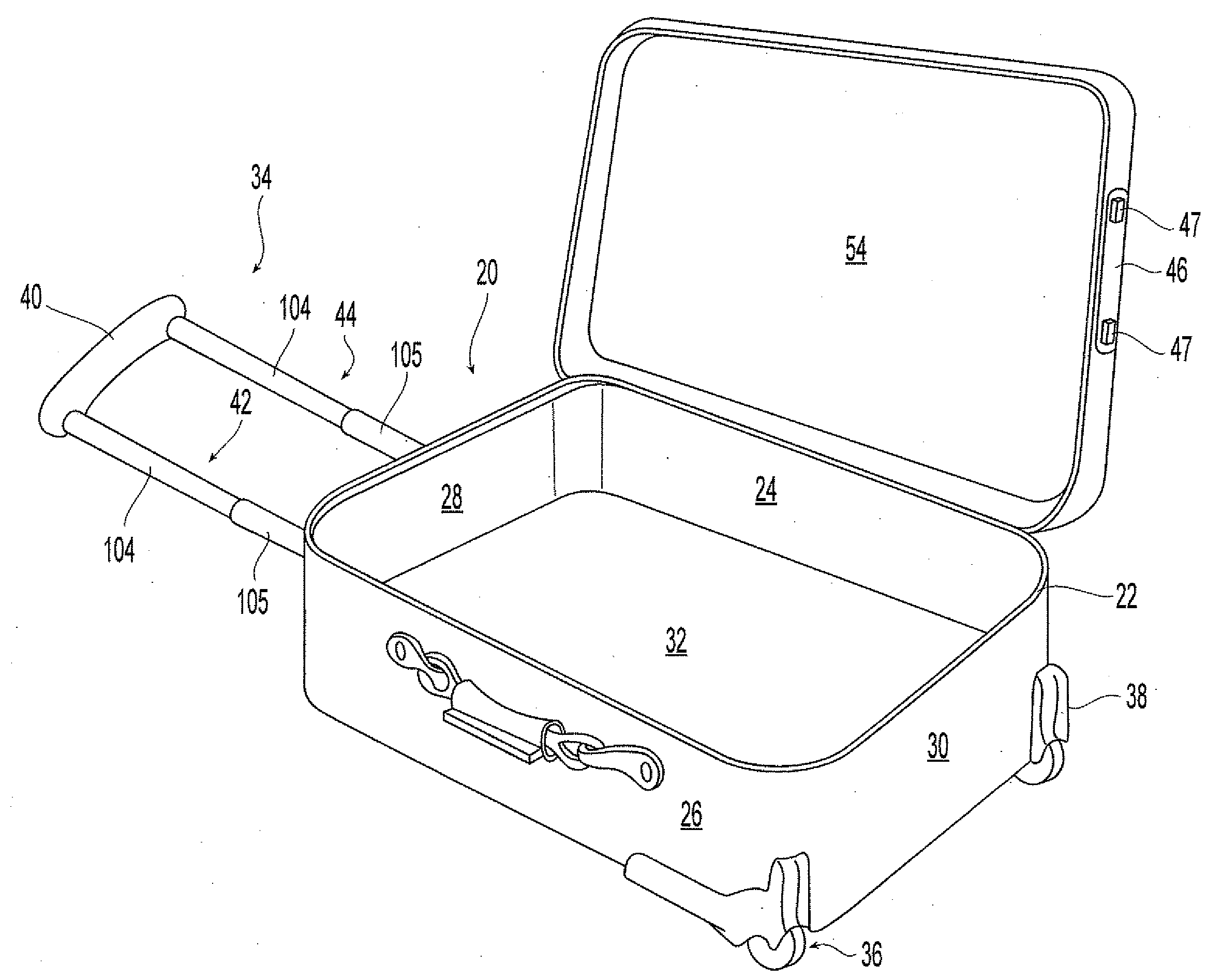

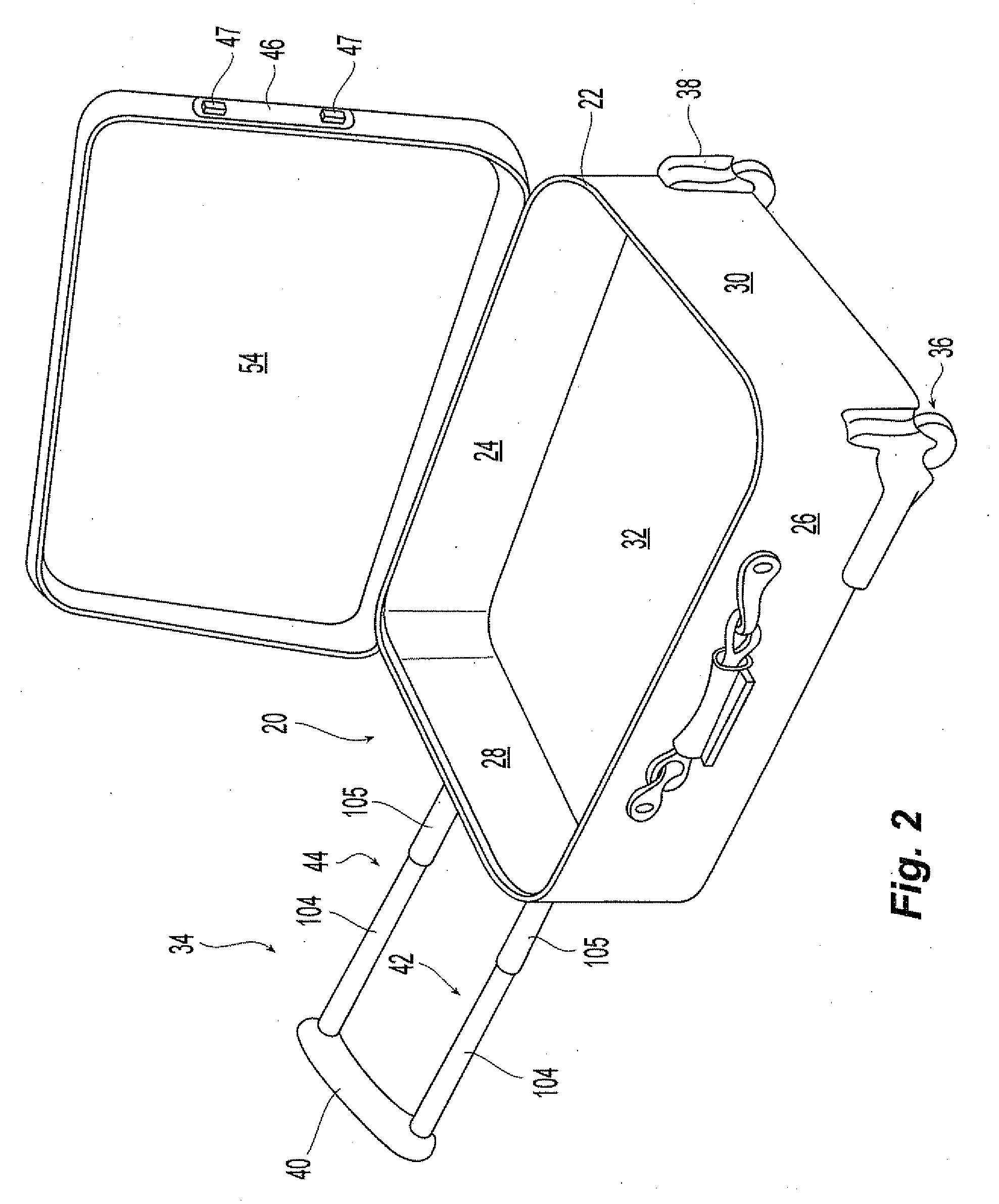

[0027]A new design is disclosed for an improved wheeled suitcase in which the retractable handle tubes and the wheel recesses are located outside of the packing area of the case to maximize the total volume available to receive packed articles, and to provide a flat bottom profile to the case interior to minimize wrinkling of packed articles. Although the disclosure will generally be discussed in relation to a wheeled suitcase application, it will be appreciated that it will be equally applicable to a wide variety of other wheeled carrying products, such as duffels, garments bags, totes, backpacks, business cases and sport bags.

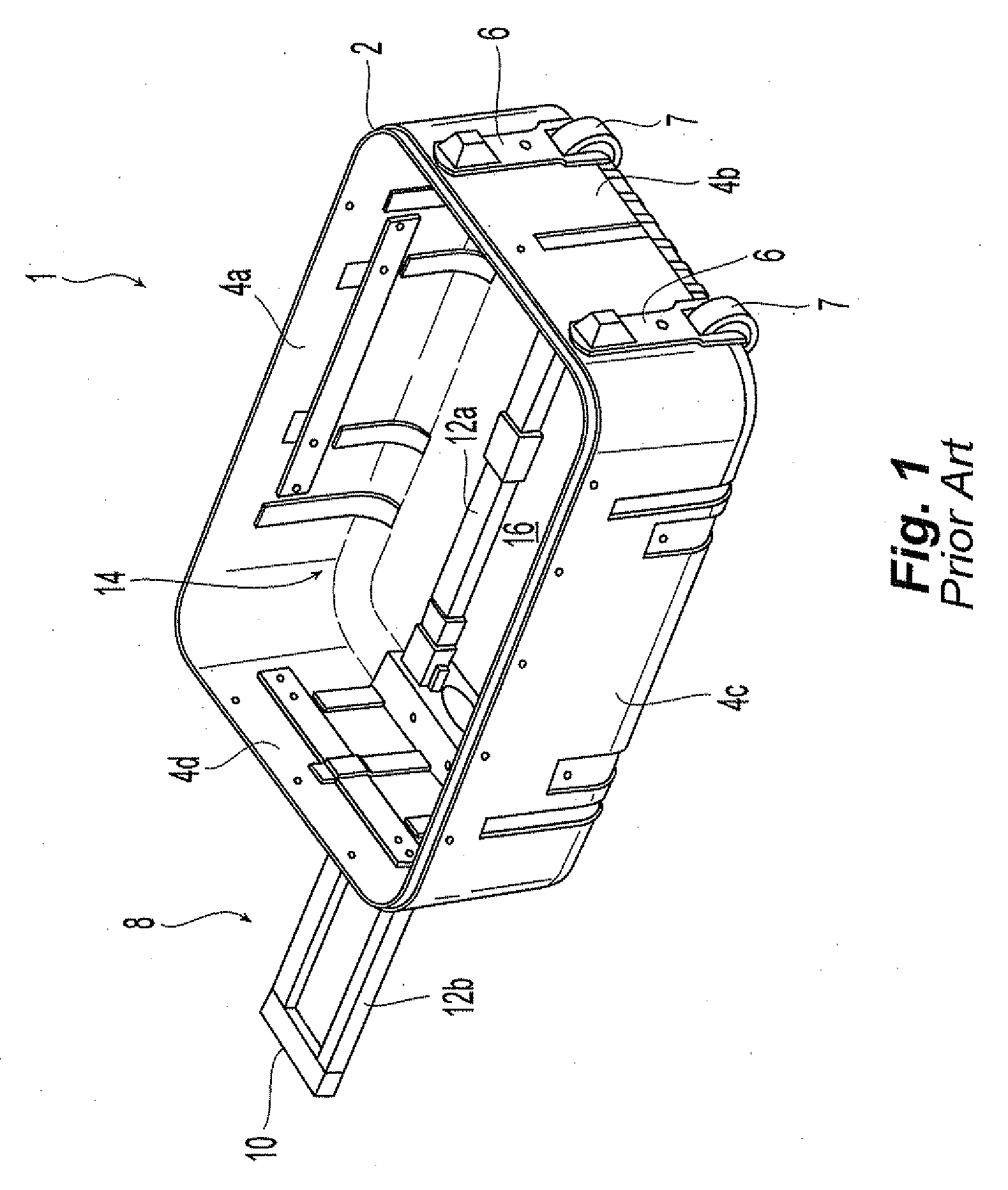

[0028]Referring to FIG. 1, a conventional wheeled suitcase 1 (shown without its cover for clarity) has a rectilinear case portion 2 comprising a plurality of walls 4a-d, a wheel base portion 6 and a handle portion 8 comprising a handle 10 connected to a pair of telescoping tubes 12a, 12b. For clarity, the suitcase is shown without the interior fabric trim, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com