Freezer and its control method

a technology of freezing chamber and control method, which is applied in the field of freezing chamber, can solve the problems of single freezing chamber not having the function of fast temperature change, and cannot meet the demands of different temperatures for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

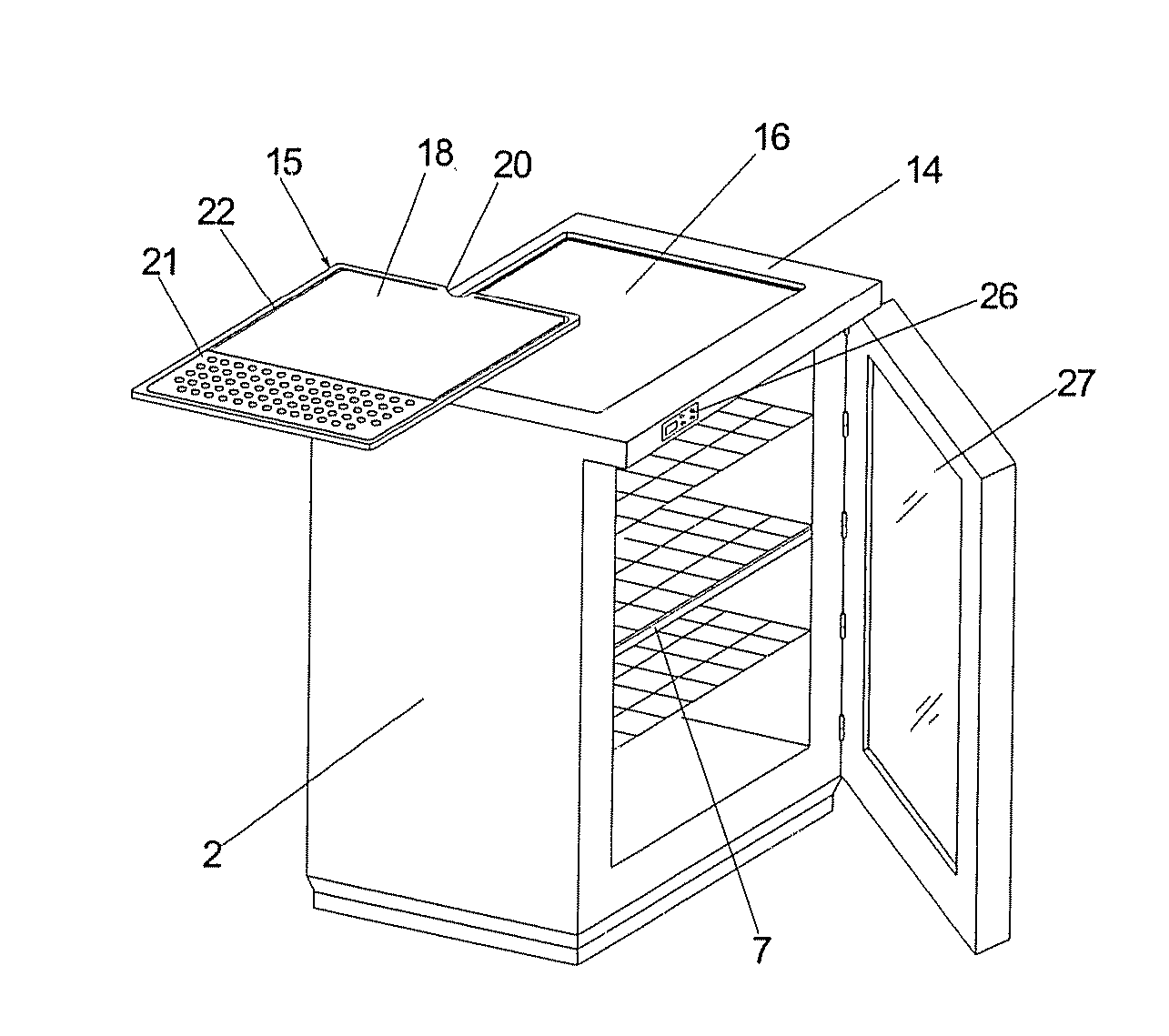

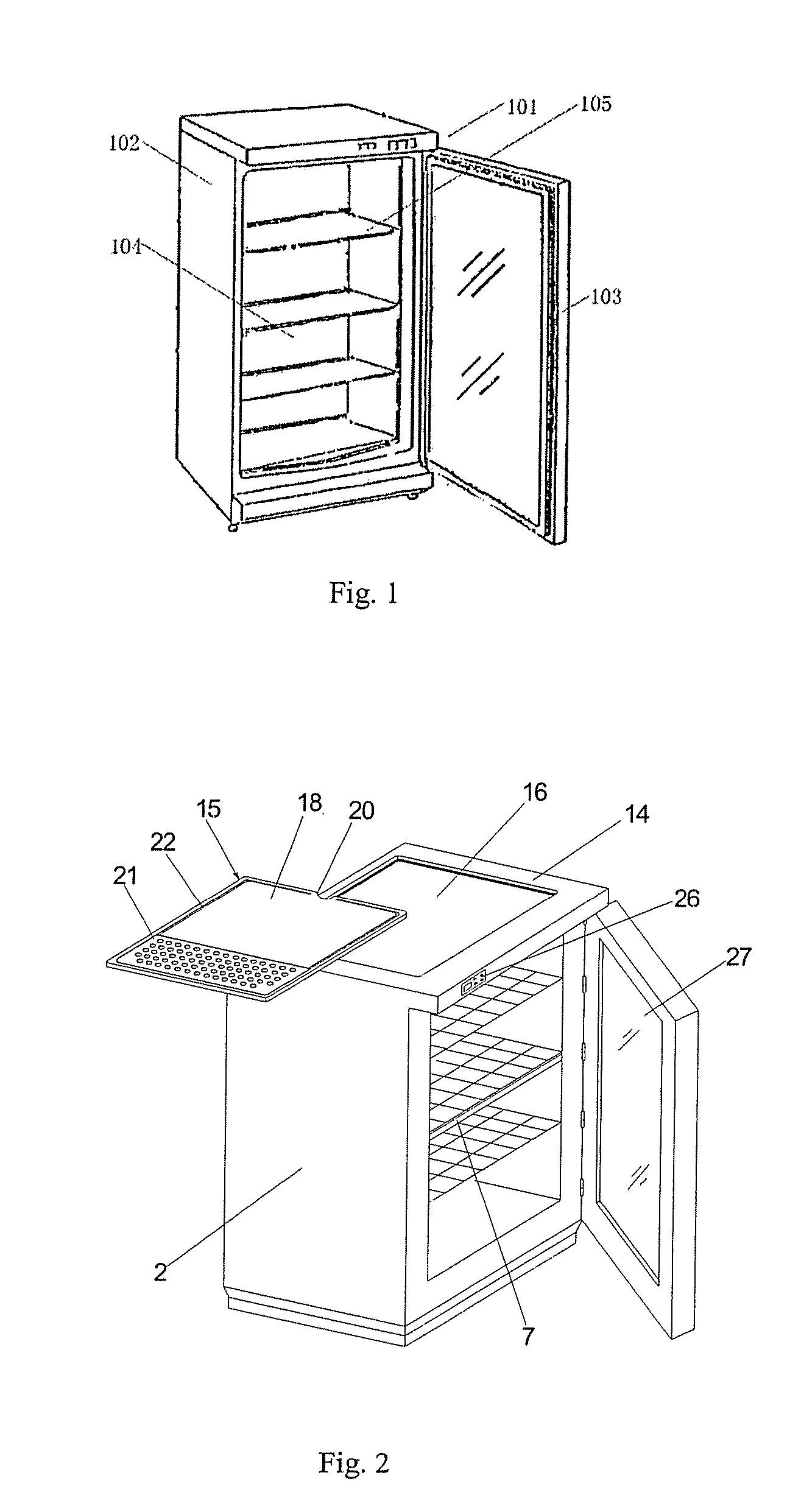

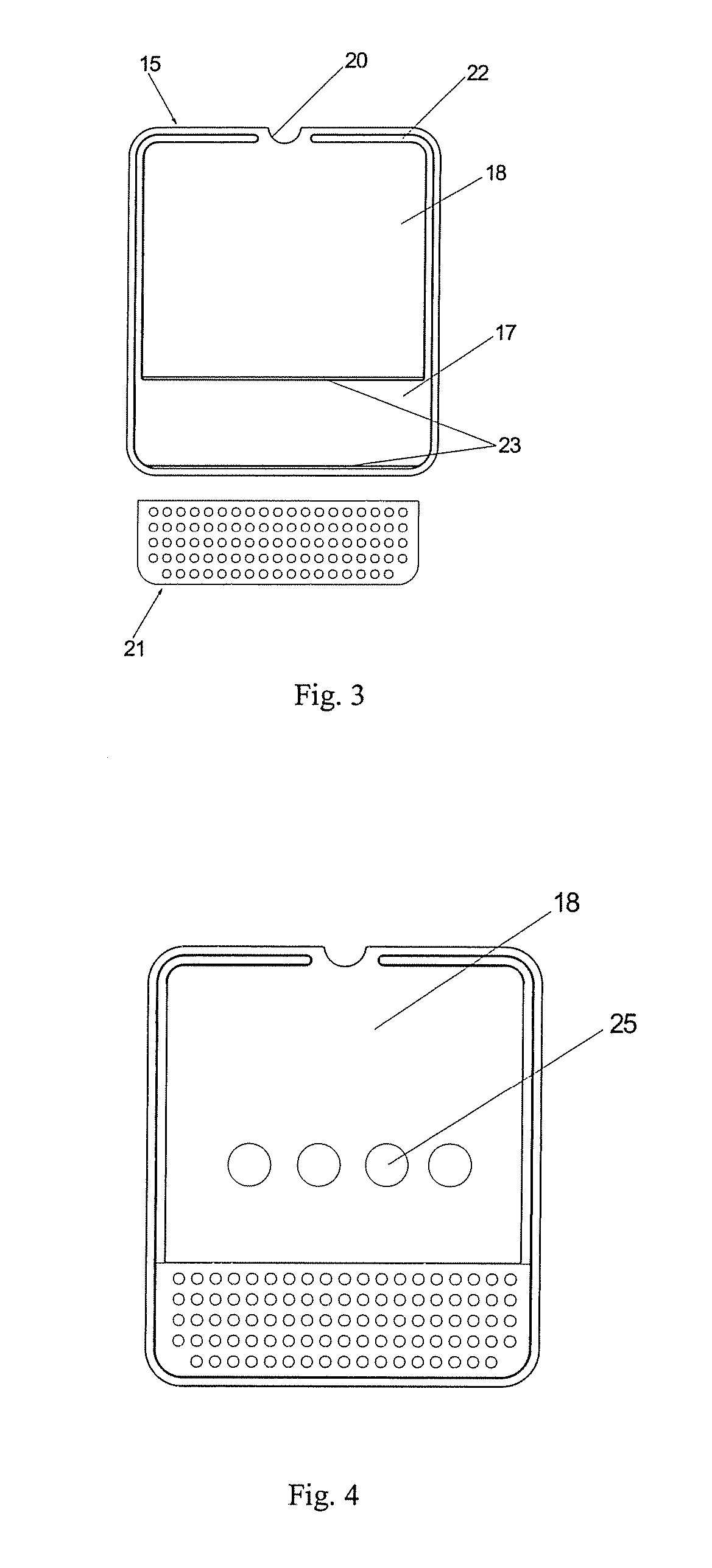

[0031]As shown in FIG. 2, groove 16 is set on the top board 14. The said pad 15 for placing wine cups and bottles and for easy wine pouring is set in groove 16. As shown in FIGS. 3, 4, and 5, one side of pad 15 is decorated surface 19 and the other side is divided into two parts. One part is pressed step shaped groove 17 and the other is flat plate 18. The surface of the said flat plate 18 is flat for easy taking out and putting in pad 15. At least one handle slot 20 is set at one side of said pad 15. The best position is the opposite side of step shaped groove 17 on flat plate 18. Water guiding groove 22 is set at the periphery of flat plate 18. (See FIG. 3).

[0032]As shown in FIG. 3, holed-clapboard 21 is set on the said step shaped groove 23, on which users can place wine cup and pour wine, with the spilled wine flowing into stepped groove 17 through the holes. Water guiding groove 22 at the periphery of the said flat plate 18, integrated with stepped groove 17. Wine spattered on ...

embodiment 2

[0034]The structure of clapboard to adjust temperature 7 explained in this embodiment is shown in FIG. 6. The clapboard to adjust temperature 7 includes a board with front and back sealed with tape 13 (only front sealing tape is shown), making the front part joint glass door body 27 (see FIG. 2) and the back joint the internal wall of the chamber to separate the upper and lower spaces for constant temperatures in the two temperature zones (see FIG. 7). Clapboard 7 can be adjusted between the upper and lower ribs, realizing the changing of the upper and lower spaces. When different amounts of red wine and wine are kept, the spaces can be adjusted freely, realizing the division of different temperature zones. Air return openings are set in the upper and lower temperature zones, for one each, so the temperatures of the upper and lower spaces can be controlled independently, without interfering each other.

embodiment

[0035]This embodiment is a kind of fast cooling chamber of freezer.

[0036]The freezer mentioned in this invention is a air cooling one, on which normally has one ventilation opening. Fan 11 is set as shown in FIG. 7. Air return opening 8 is placed at a proper position in the freezer. Cold air is blown out by fan 11 from air return opening 8 and enters freezing zone through air return opening 8. Air contacts the evaporator in the freezing zone to have the circulating air temperature decreased.

[0037]Fast cooling chamber 10 mentioned in this invention is set optimally on the top of the freezer according to the common place of the ventilation opening.

[0038]The said fast cooling chamber 10 includes air outlet pipe 12. Pipe 12 is fixed on the wall of the freezer, just wrapping the air outlet as shown in the figures. The rear end of outlet pipe 12 in U shape for obtaining enough strength is fixed on the rear wall of the freezer, with the upper side fixed on the upper part inside the freezer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com