Process and Apparatus for Integrated Heavy Oil Upgrading

a technology of heavy oil and process equipment, applied in the field of crude oil process and equipment for treatment, can solve the problems of poor hydrocracking conversion, low reactivity, and high coking tendency, and achieve the effects of improving the performance of all three processes, minimizing coke production, and maximizing or optimizing gasoline yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

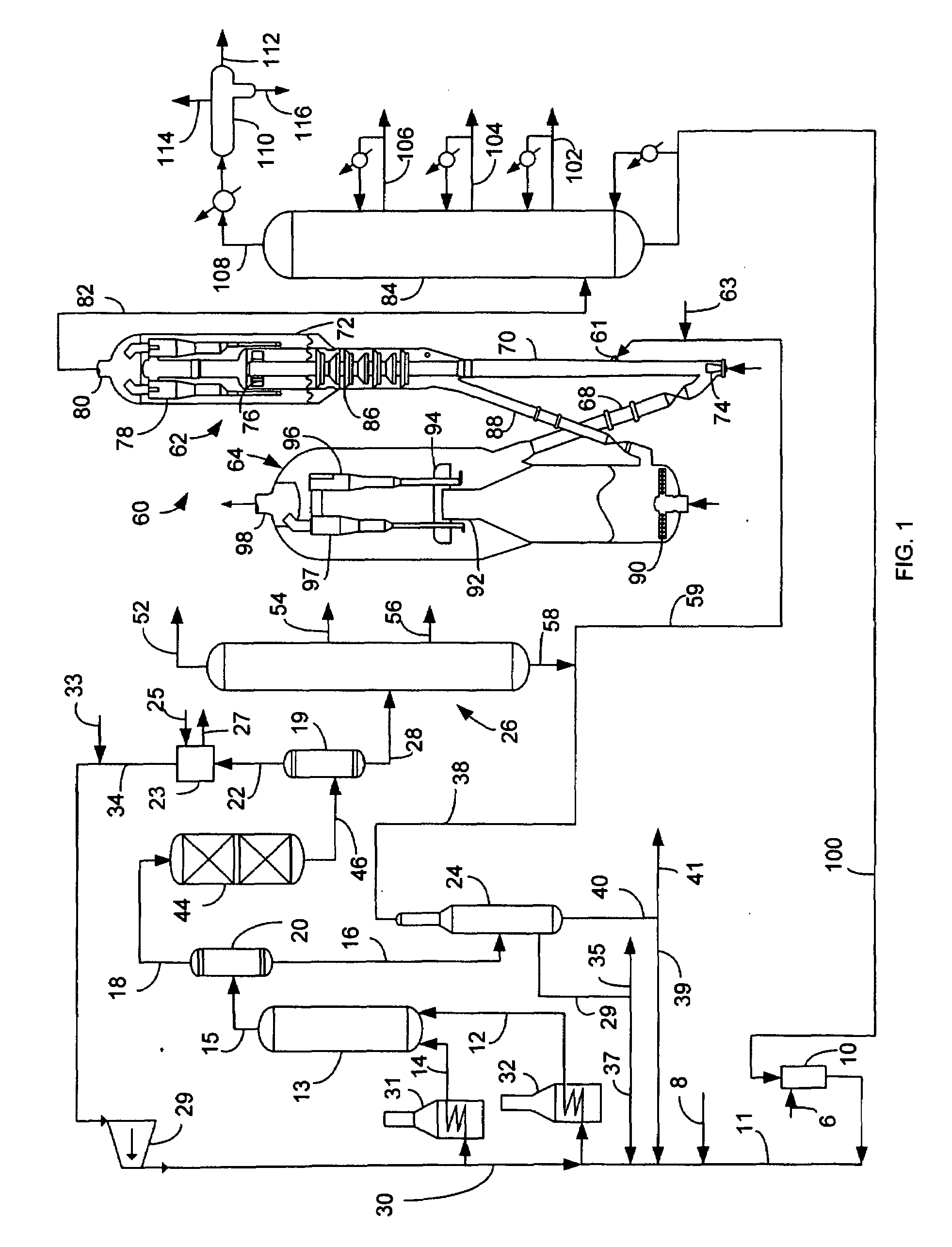

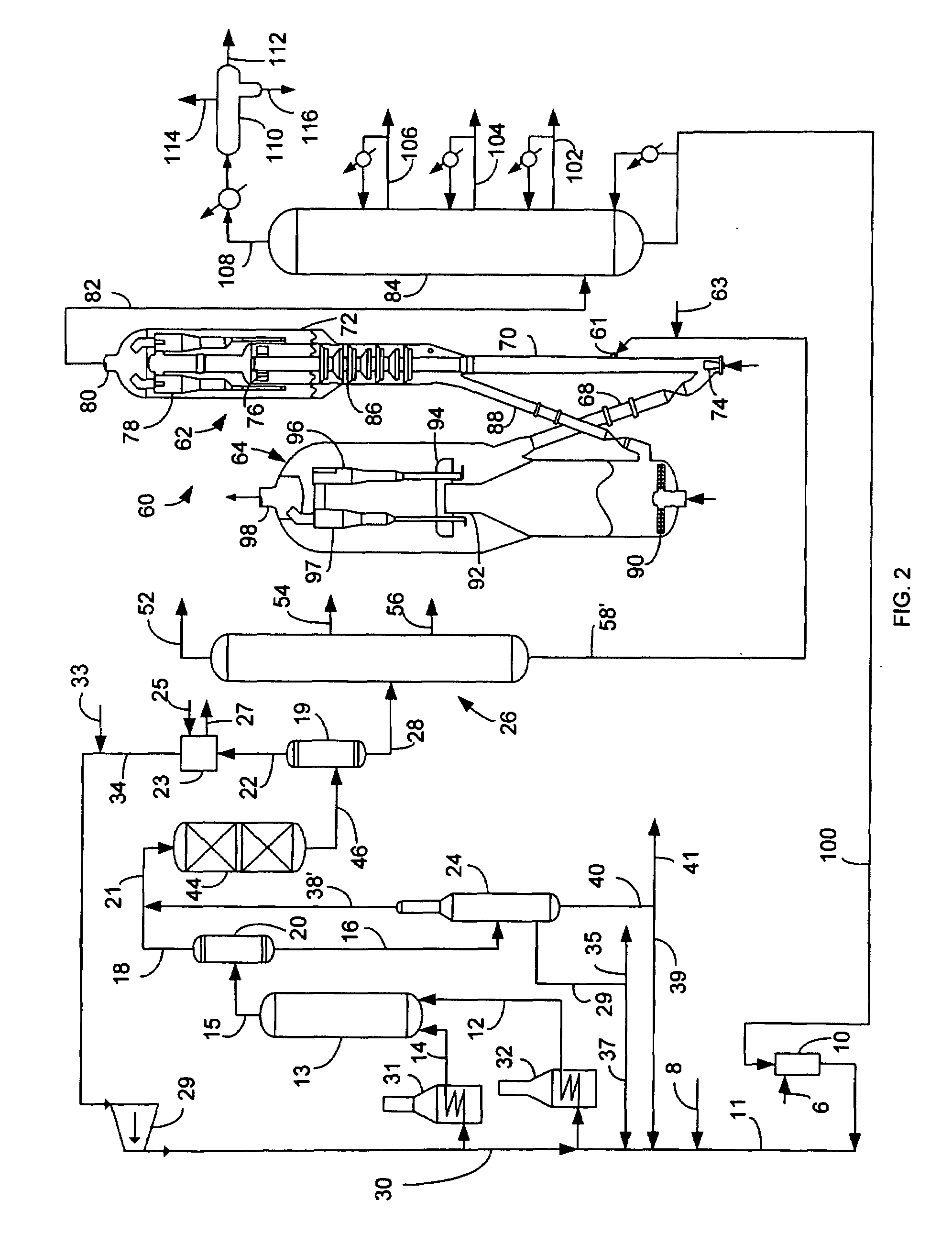

[0013]The process and apparatus of this invention is capable of processing a wide range of heavy hydrocarbon feedstocks. It can process aromatic feedstocks, as well as feedstocks which have traditionally been very difficult to hydroprocess, e.g. vacuum bottoms, visbroken vacuum residue, deasphalted bottom materials, off-specification asphalt, sediment from the bottom of oil storage tanks, etc. Suitable feeds include atmospheric residue boiling at about 650° F. (343° C.), heavy vacuum gas oil (VGO) and vacuum residue boiling at about 800° F. (426° C.) and vacuum residue boiling above about 950° F. (510° C.). Throughout this specification, the boiling temperatures are understood to be the atmospheric equivalent boiling point (AEBP) as calculated from the observed boiling temperature and the distillation pressure, for example using the equations furnished in ASTM method D1160. Furthermore, the term “pitch” is understood to refer vacuum residue, or material having an AEBP of greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com