Support frame unit for swimming pool assembly

a technology for supporting frame units and swimming pools, which is applied in the direction of gyms, construction, buildings, etc., can solve the problems of generating problems, requiring a long time, and complicated installation of shoes b>40, and achieve the effect of reducing load and stably enduring hydraulic pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Now, a preferred embodiment of the present invention will be described in detail with reference to the annexed drawings.

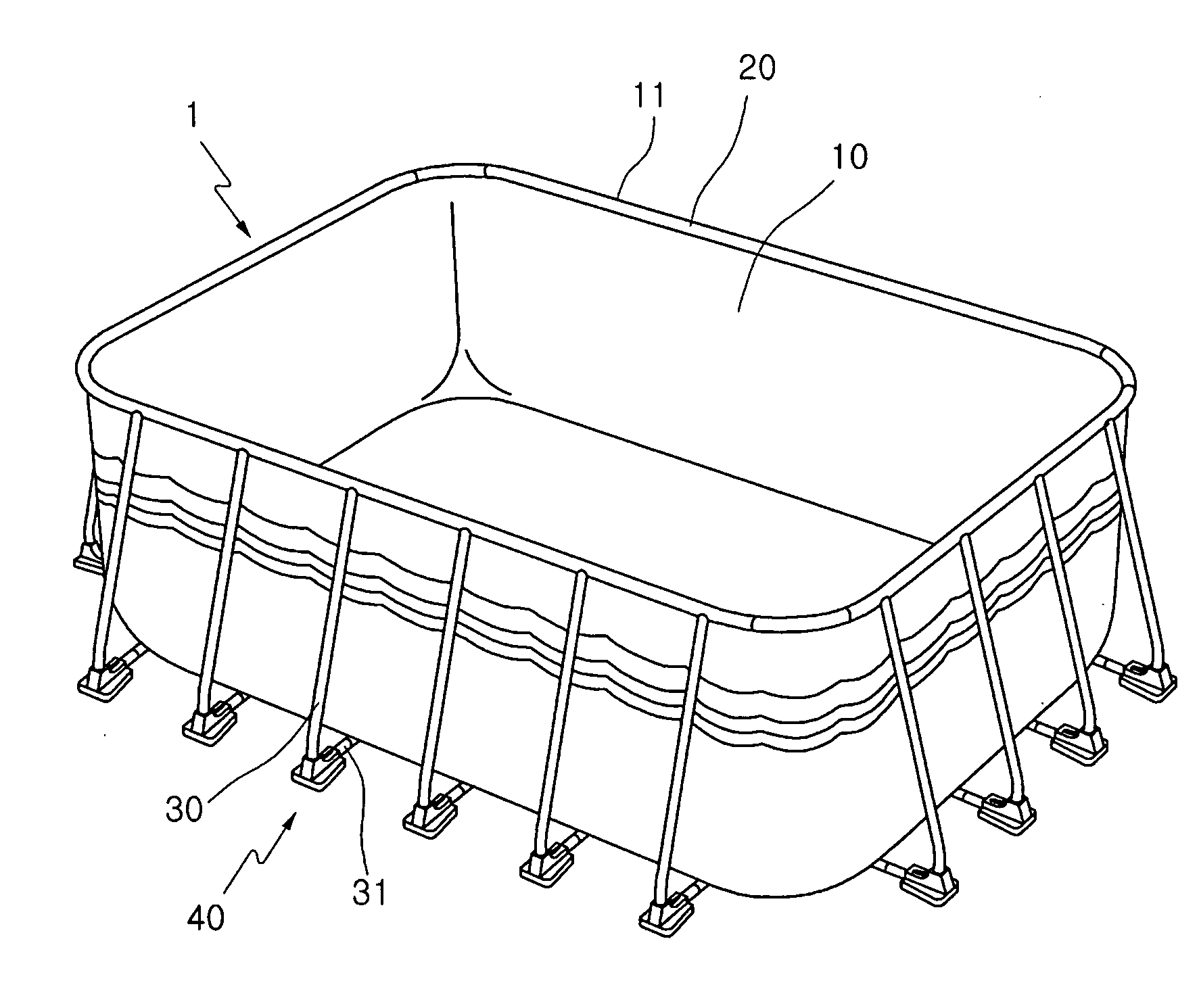

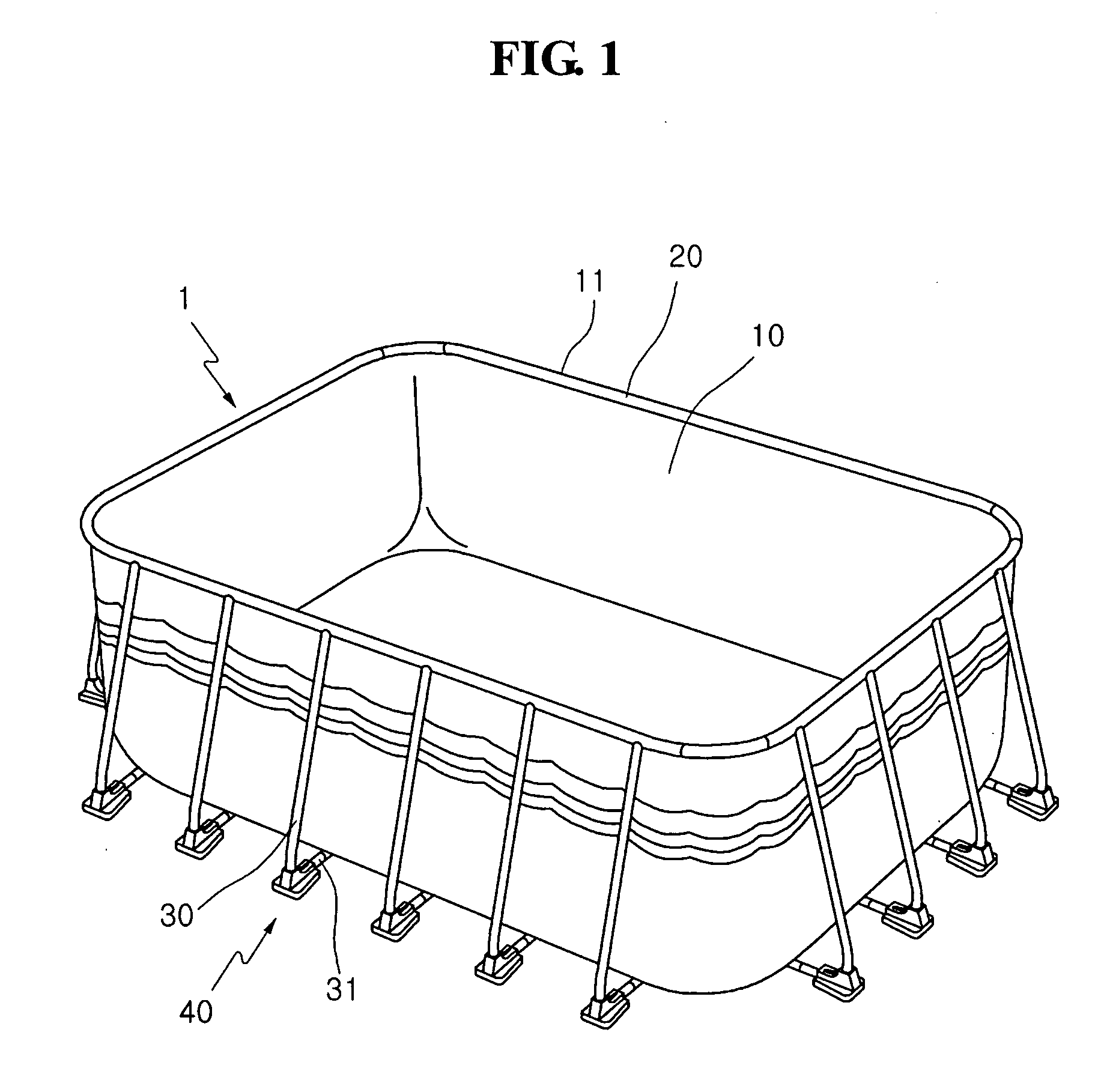

[0032]A support frame unit for a swimming pool assembly of the present invention is disposed such that the support frame unit surrounds the periphery of a pool body 1, and supports a surrounding wall 10 so as to prevent the surrounding wall 10 from being sunken due to hydraulic pressure applied to the surrounding wall 10 of the pool body 1.

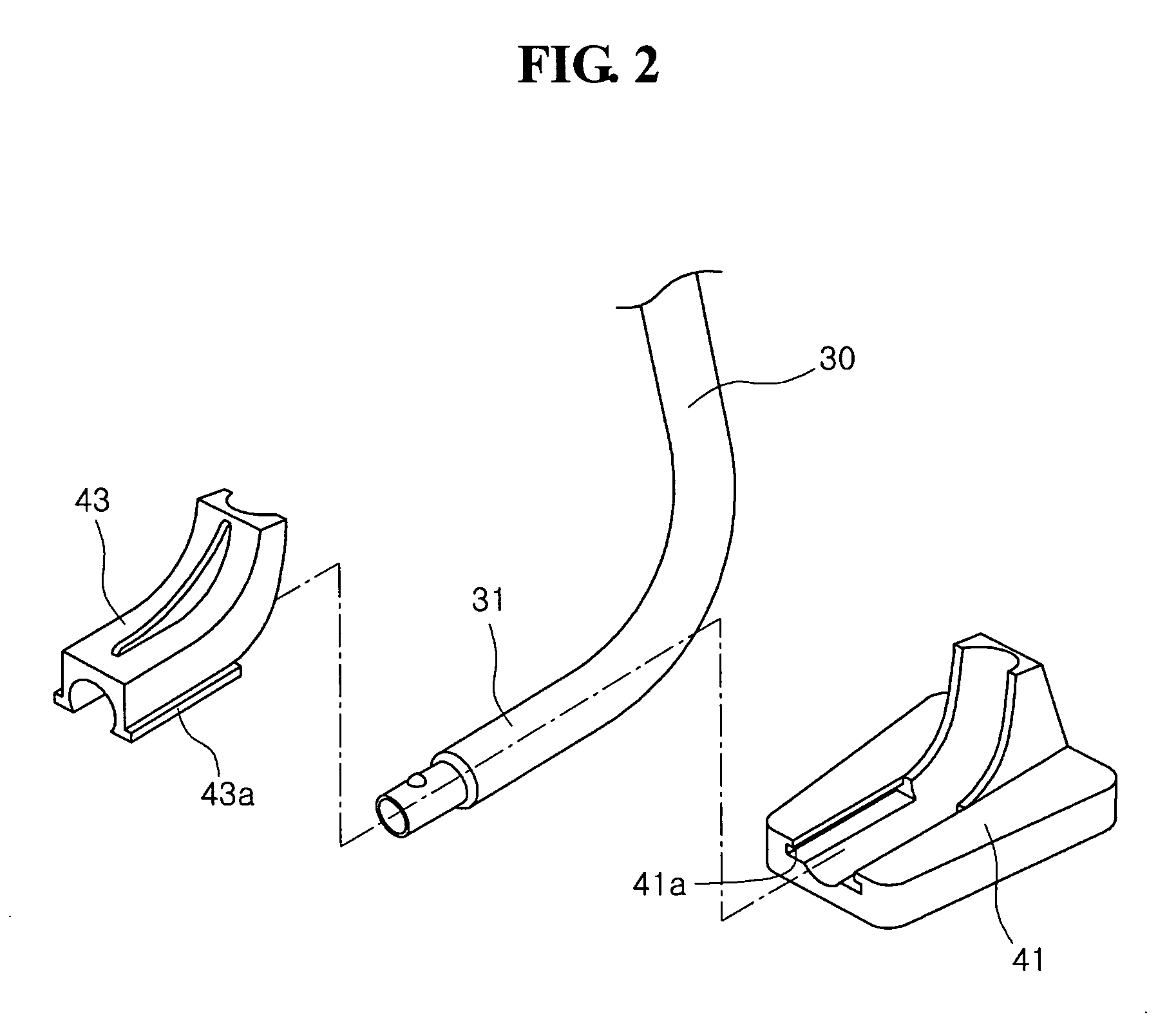

[0033]With reference to FIG. 3, the support frame unit in accordance this embodiment includes first and second vertical rods 110 and 120, first and second shoes 210 and 220, and a prop pipe 300, which are prepared in a set. Thus, plural sets of the support frame units are disposed at regular intervals along the surrounding wall 10 of the pool body 1.

[0034]The first and second vertical rods 110 and 120 have a rectilinear shape having a designated length. Upper ends of the first and second vertical rods 110 and 120 are detach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com