Anchor monitoring system

a monitoring system and anchor technology, applied in the direction of anchors, mooring equipment, vessel construction, etc., can solve the problems of plastic deformation and common permanent elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

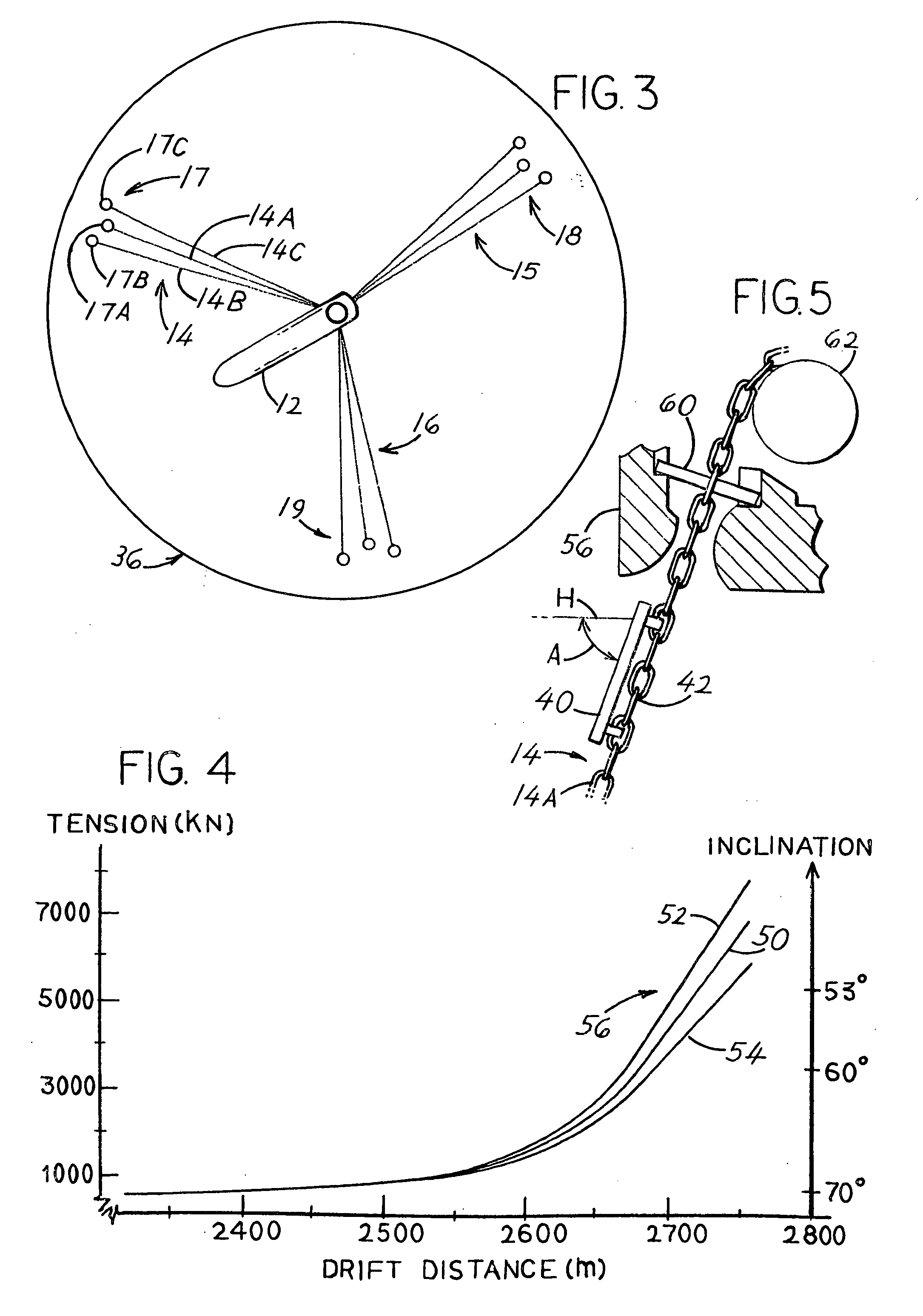

[0012]FIG. 1 illustrates a mooring system 10 that moors a vessel 12 (which is herein defined as any structure that floats at the sea surface) by the use of sets of mooring lines 14, 15, 16 (FIG. 3) that extend in catenary curves to anchors 17, 18, 19 at the sea floor. A riser 20 extends from a platform 22 on the sea floor 23 up to the vessel, and is useful to carry fluids such as hydrocarbons, or to carry tools, between them. The vessel has a turret 24 that allows the vessel to weathervane (the vessel can turn about the turret axis 26 without limit while the turret does not turn) and the mooring lines and riser connect to a chain table on the turret. The mooring lines are used to limit drift of the vessel from an initial position that the vessel assumes in a calm sea, as shown in FIG. 1, in order to avoid damage to the riser.

[0013]Each mooring line such as 14 includes a cable 30 of a polymer such as polyester, and lengths of steel chains 32, 34 at the upper and lower ends of the moo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com