Injection Device

a technology of injection device and syringe, which is applied in the direction of intravenous device, medical syringe, syringe, etc., can solve the problems of affecting so as to reduce the exposure to contaminants, avoid syringe movement, and ensure the effect of syringe movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

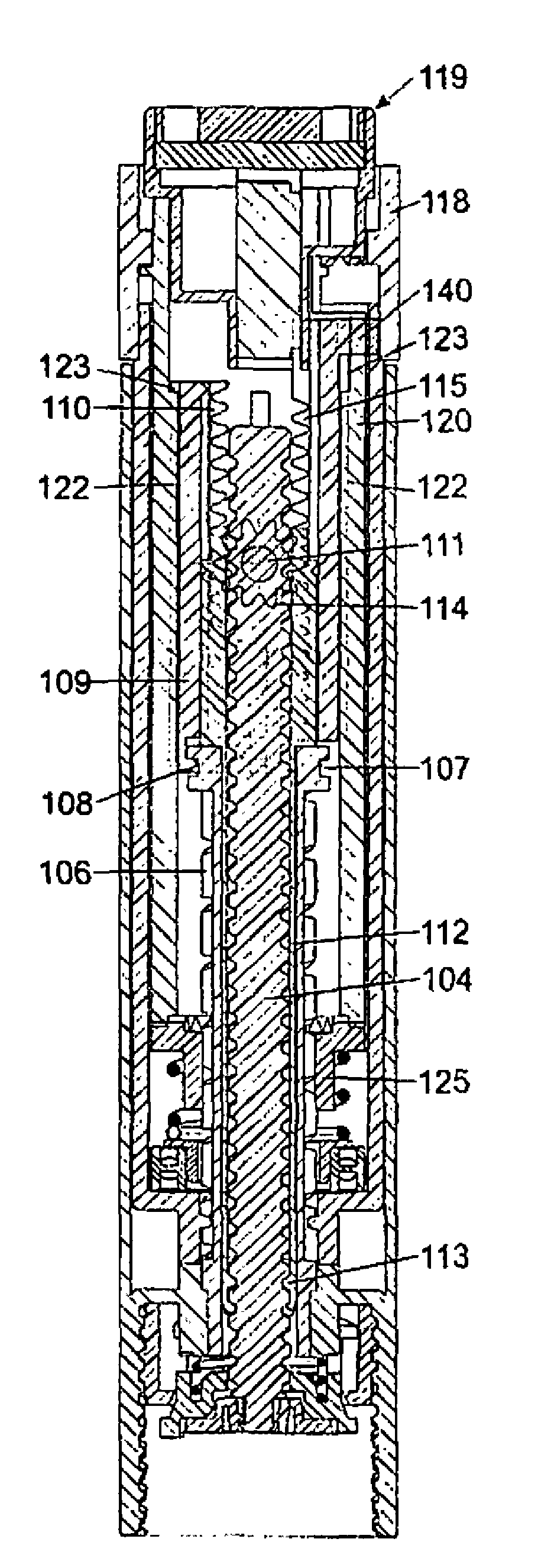

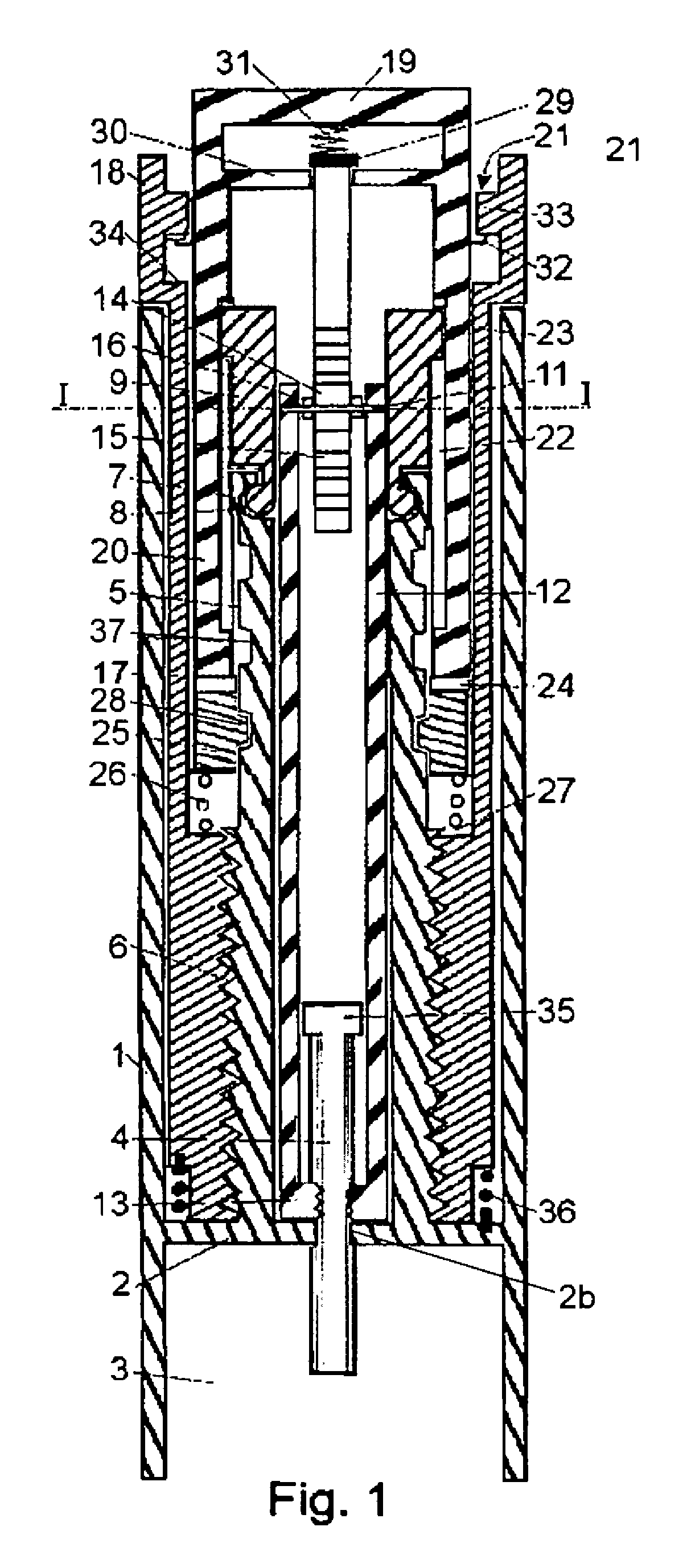

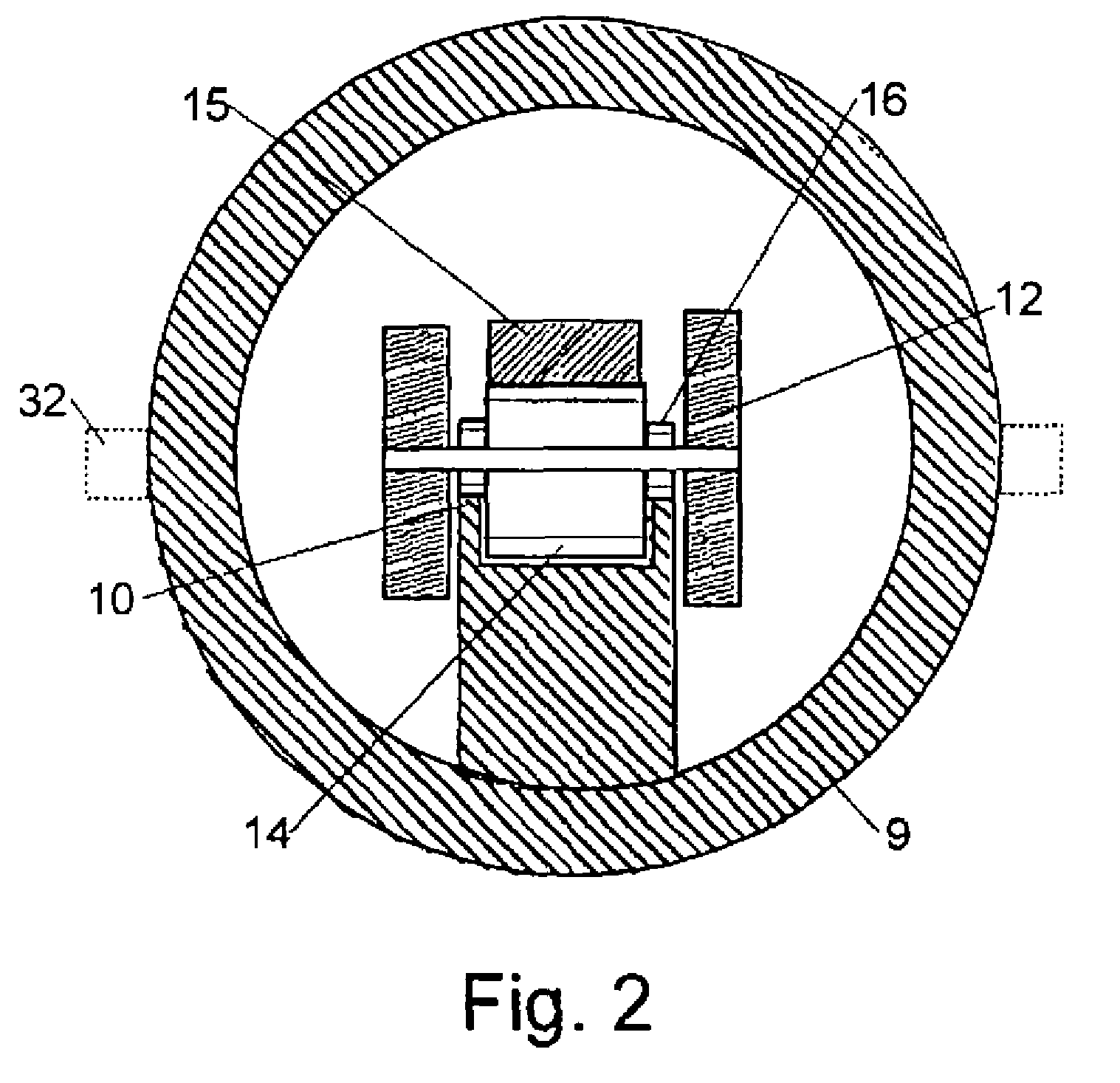

[0049]The device shown in the appended drawings is shown as an injector pen, which pen has an elongated body with a central axis. However, other forms are within the scope of the invention.

[0050]In the device shown in FIG. 1 an elongated cylindrical housing 1 has a partitioning wall 2 which divides the housing in a compartment containing a dose setting mechanism and a compartment 3 designed for the accommodation of a not shown ampoule. The partitioning wall 2 is provided with an opening extending there through. Alternatively, the wall may be replaced by an insert which is secured against rotational and axial motion with respect to the main structure of the housing 1, the opening being formed in said insert. A piston rod 4 having a first thread 4a and an additional longitudinally extending track 4b formed in or on the piston rod 4, extends through the opening 2b, which is provided with one or more ribs which mates and engages the additional longitudinal extending track 4b.

[0051]In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com