Pressure-sensitive adhesive sheet

a technology of adhesive sheets and adhesive sheets, applied in the direction of film/foil adhesives, transportation and packaging, synthetic resin layered products, etc., can solve the problems of deterioration of designability and decorativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

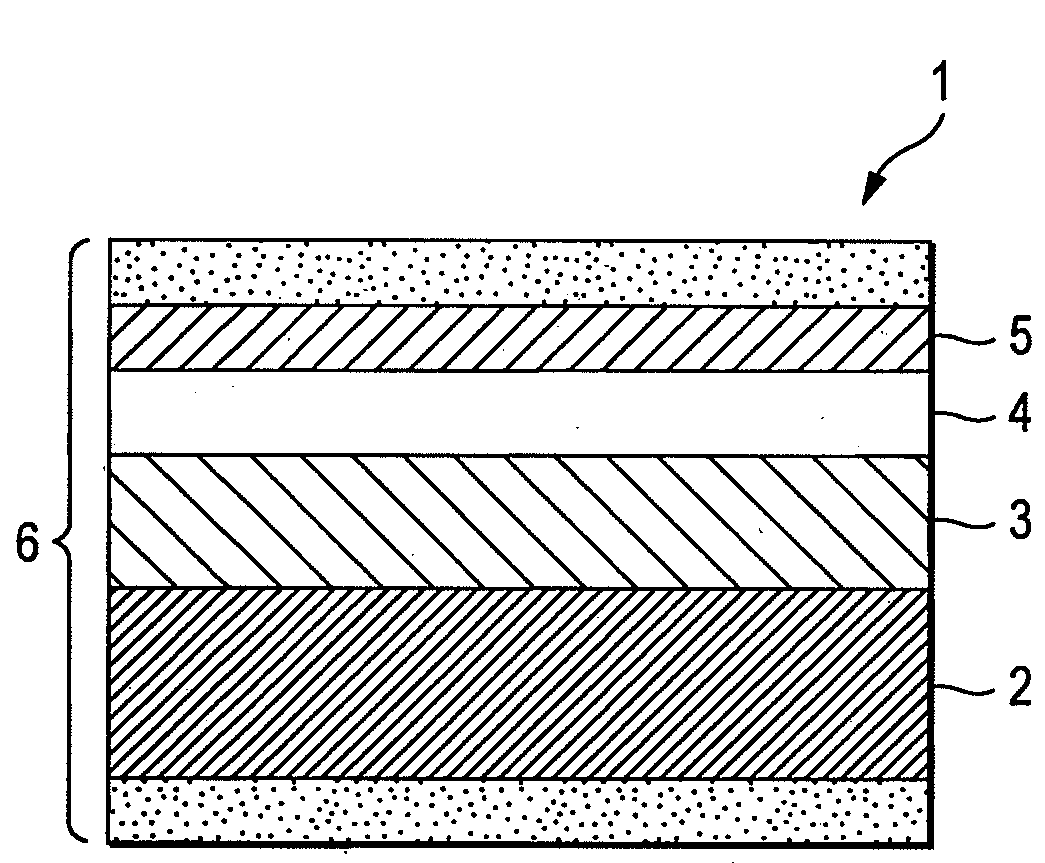

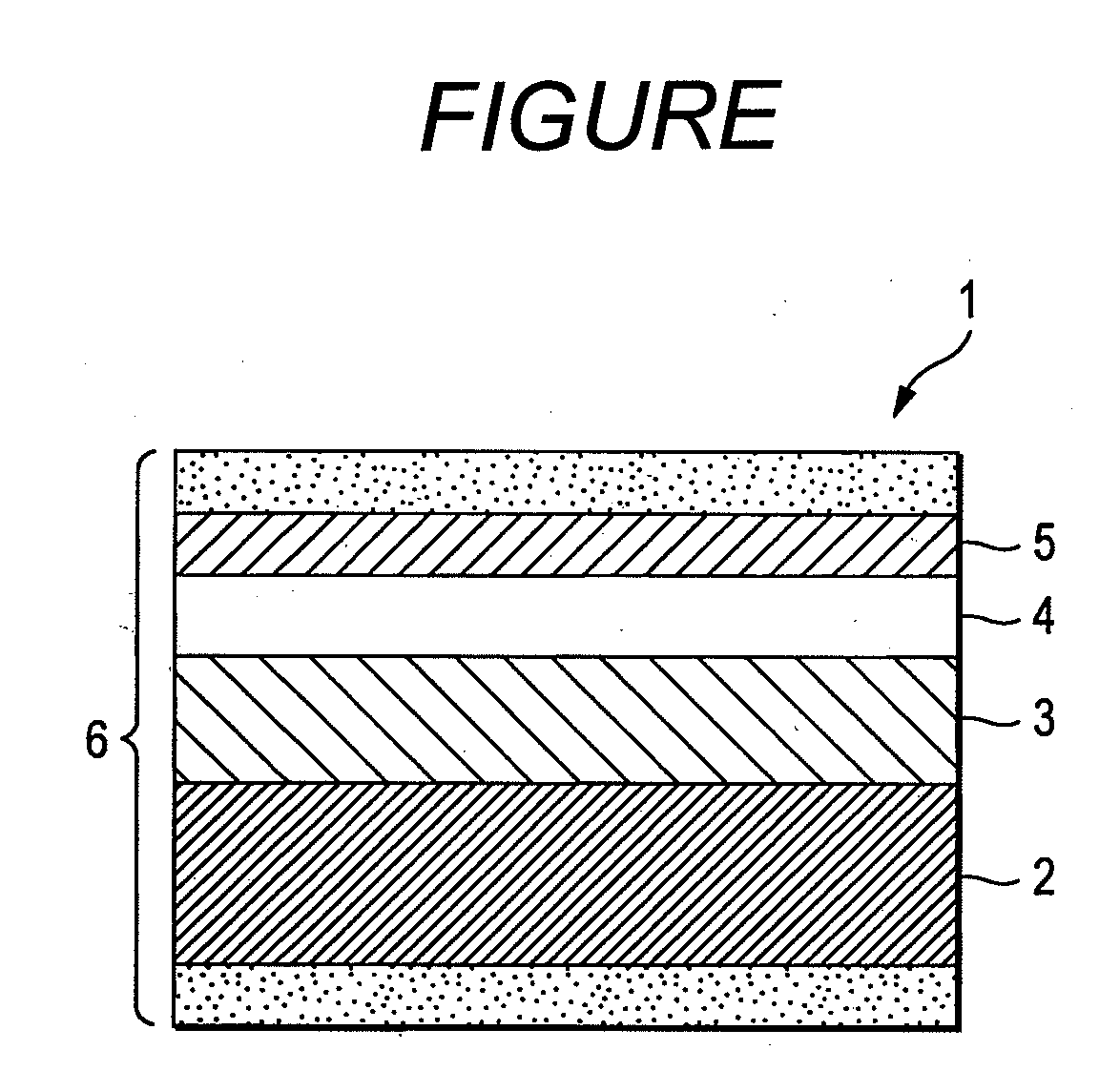

[0135]On one side of a white polyethylenetelephthalate (PET) film (a tetron film “TU3#13”, thickness: 13 μm; manufactured by Teijin DuPont Films Japan Limited), multilayer printing of white / silver / black / black / black / white / white / red was performed in this order by using inks (NB-300; manufactured by Dainichiseika Color & Chemicals Mfg. Co. Ltd.) in accordance with a gravure printing method to obtain a base material having a thickness of 24 μm. The acrylic pressure-sensitive adhesive obtained as described above was coated on both sides of the base material in such a manner that the thicknesses of the pressure-sensitive adhesive layers became 5 μm to obtain a double-sided adhesive tape (double-sided pressure-sensitive adhesive sheet) having a thickness of 34 μm.

[0136]Note that “white”, “black”, and the like described above are types of the printing inks, and details thereof will be described later.

[0137]A structure of the double-sided pressure-sensitive adhesive sheet was: transparent pr...

example 2

[0138]On one side of a white polyethylenetelephthalate (PET) film (a tetron film “TU3#13”, thickness: 13 μm; manufactured by Teijin DuPont Films Japan Limited), multilayer printing of white / silver / black / black / black / white / white / pink was performed in this order by using inks (NB-300; manufactured by Dainichiseika Color & Chemicals Mfg. Co. Ltd.) in accordance with a gravure printing method to obtain a base material having a thickness of 24 μm. The acrylic pressure-sensitive adhesive obtained as described above was coated on both sides of the base material in such a manner that the thicknesses of the pressure-sensitive adhesive layers became 5 μm to obtain a double-sided adhesive tape (double-sided pressure-sensitive adhesive sheet) having a thickness of 34 μm.

example 3

[0139]On one side of a white polyethylenetelephthalate (PET) film (a tetron film “TU3#13”, thickness: 13 μm; manufactured by Teijin DuPont Films Japan Limited), multilayer printing of white / silver / black / black / black / white / white / dark blue was performed in this order by using inks (NB-300; manufactured by Dainichiseika Color & Chemicals Mfg. Co. Ltd.) in accordance with a gravure printing method to obtain a base material having a thickness of 24 μm. The acrylic pressure-sensitive adhesive obtained as described above was coated on both sides of the base material in such a manner that the thicknesses of the pressure-sensitive adhesive layers became 5 μm to obtain a double-sided adhesive tape (double-sided pressure-sensitive adhesive sheet) having a thickness of 34 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittance | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com