Pneumatic painting apparatus with spray gun, heater device, and dehumidifier/drier device provided with a regenerating device for the adsorptive agent for fluidifying the paint

a technology of fluidifying paint and pneumatic painting, which is applied in the direction of spray nozzles, medical atomisers, coatings, etc., can solve the problems of reducing the effective air quantity of painting, reducing and devices being practically unusable, so as to reduce the dehumidification efficiency, eliminate the absorbed humidity, and improve the fluidity of painting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

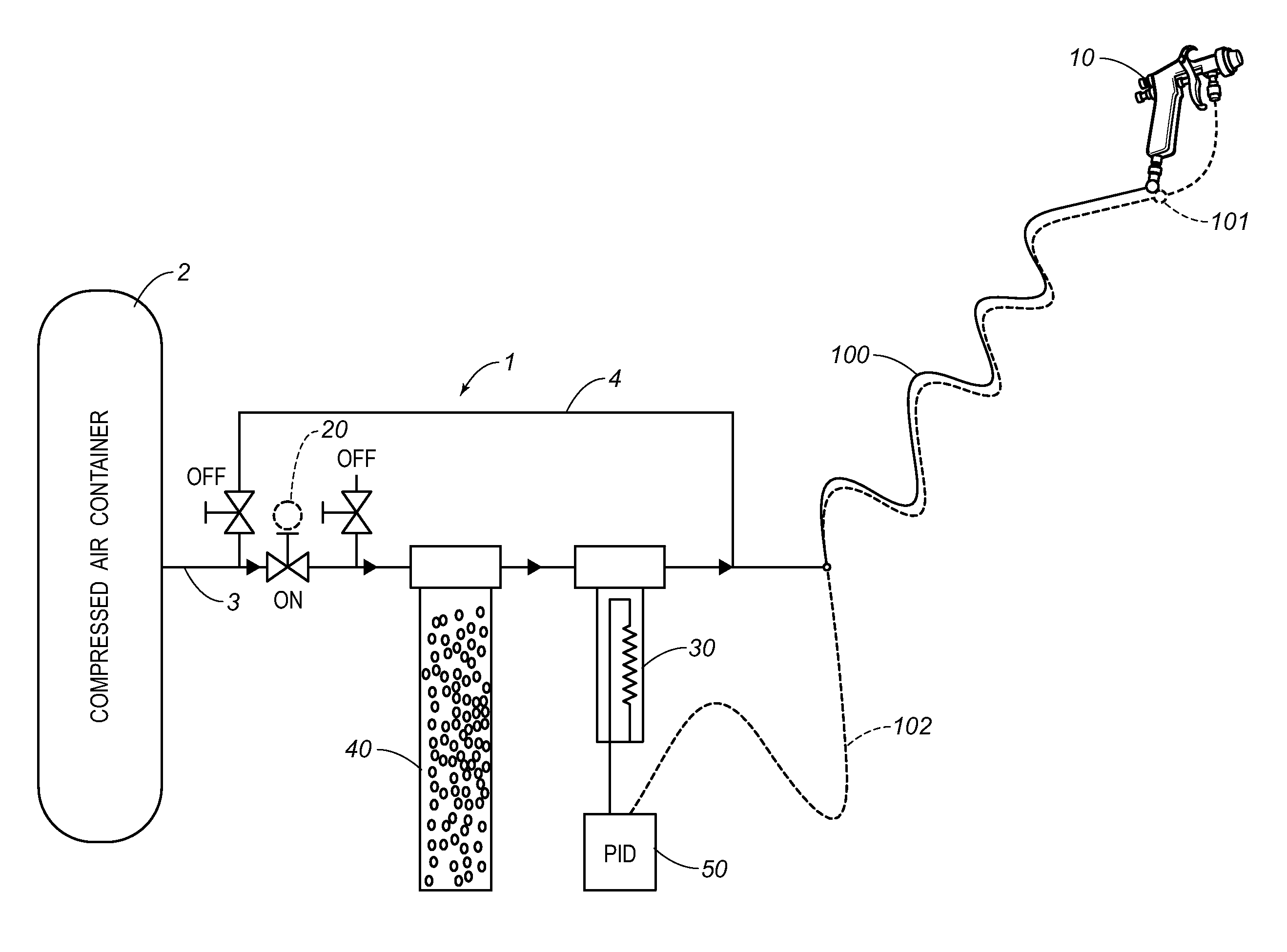

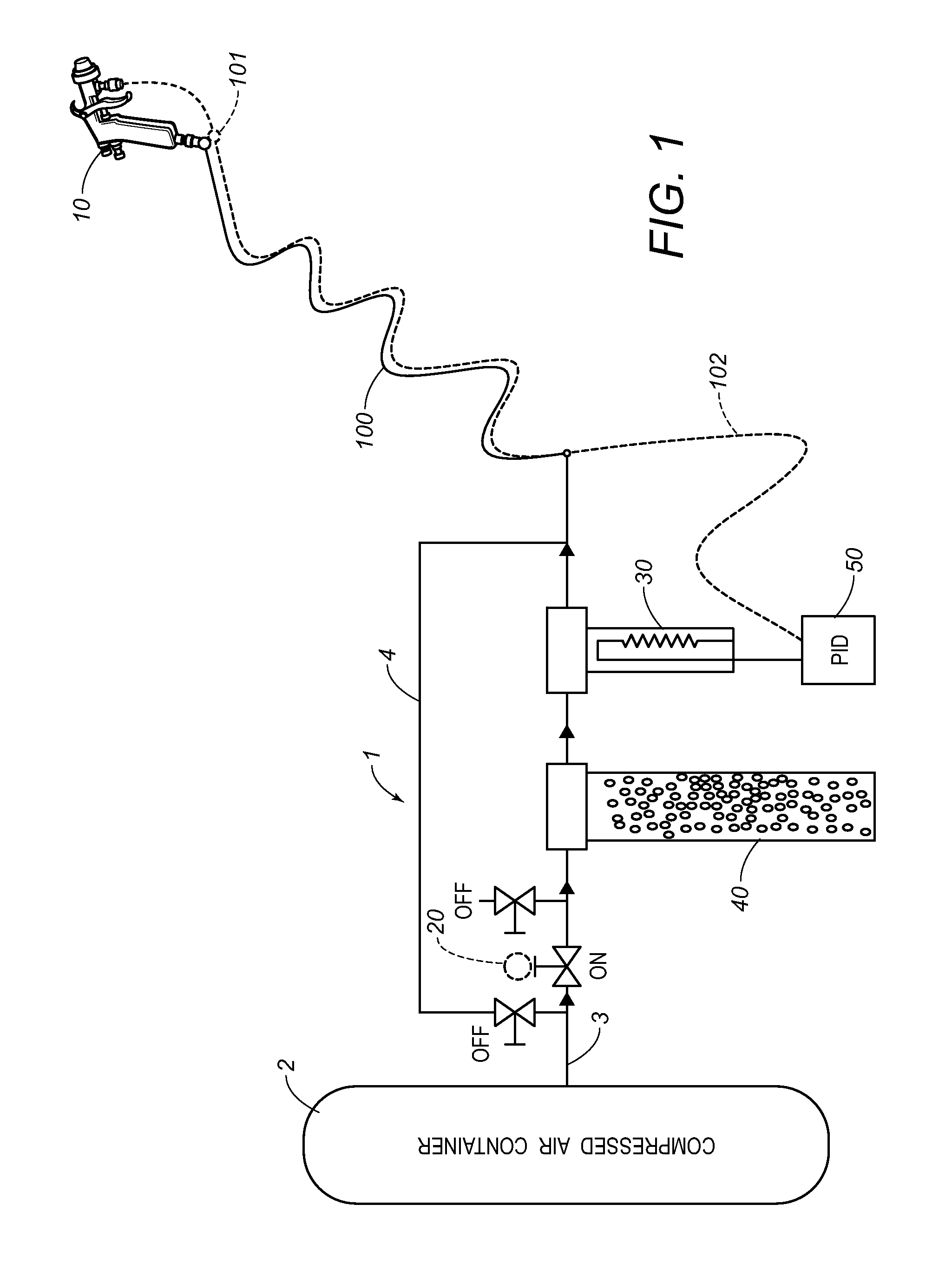

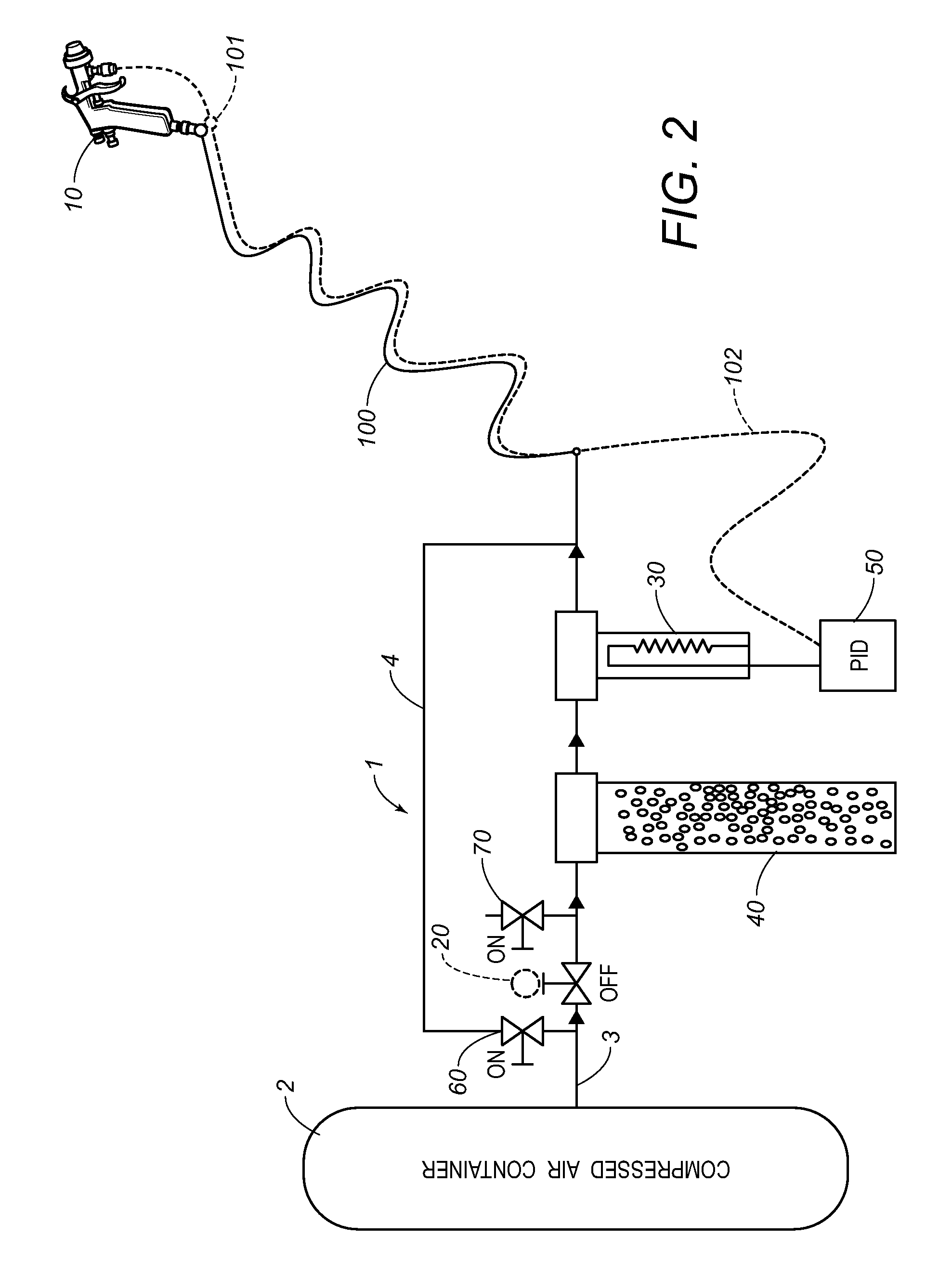

[0076]The present invention is a painting apparatus 1 of the pneumatic type with spray gun 10, heater device 30 and de-humidifier / drier device 40 for the pressurized airflow. The de-humidifier / drier device 40 has regenerating device 4 for an adsorptive agent contained inside the de-humidifier / drier device 40, fluidifying the paint during the application on a support.

[0077]The painting apparatus 1, as represented in FIG. 1, consists of a conventional compressor group (not shown) that supplies a compressed air container 2. The compressed air container 2 has an exit for the compressed air flow inputted into the compressed air flow path circuit 3 for delivery towards at least one spray gun 10. The circuit 3, activated by means of an electro-valve 20, has a position between the supply pipe 100 of the spray gun 10 and the compressed air container 2. For the treatment of the airflow, at least one heater device 30 is conducted across the supply pipe 100 in the spray gun 10. In this case, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com