High pressure compressor and steam explosion pulping method

a high-pressure compressor and steam explosion technology, which is applied in the field of cellulosic biomass feed material pretreatment, can solve the problems of large amount of steam, large pressure, and expansion of steam in the cells of feed materials, and achieve the effect of reducing the pressure of the pressurized feed material and rapid pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

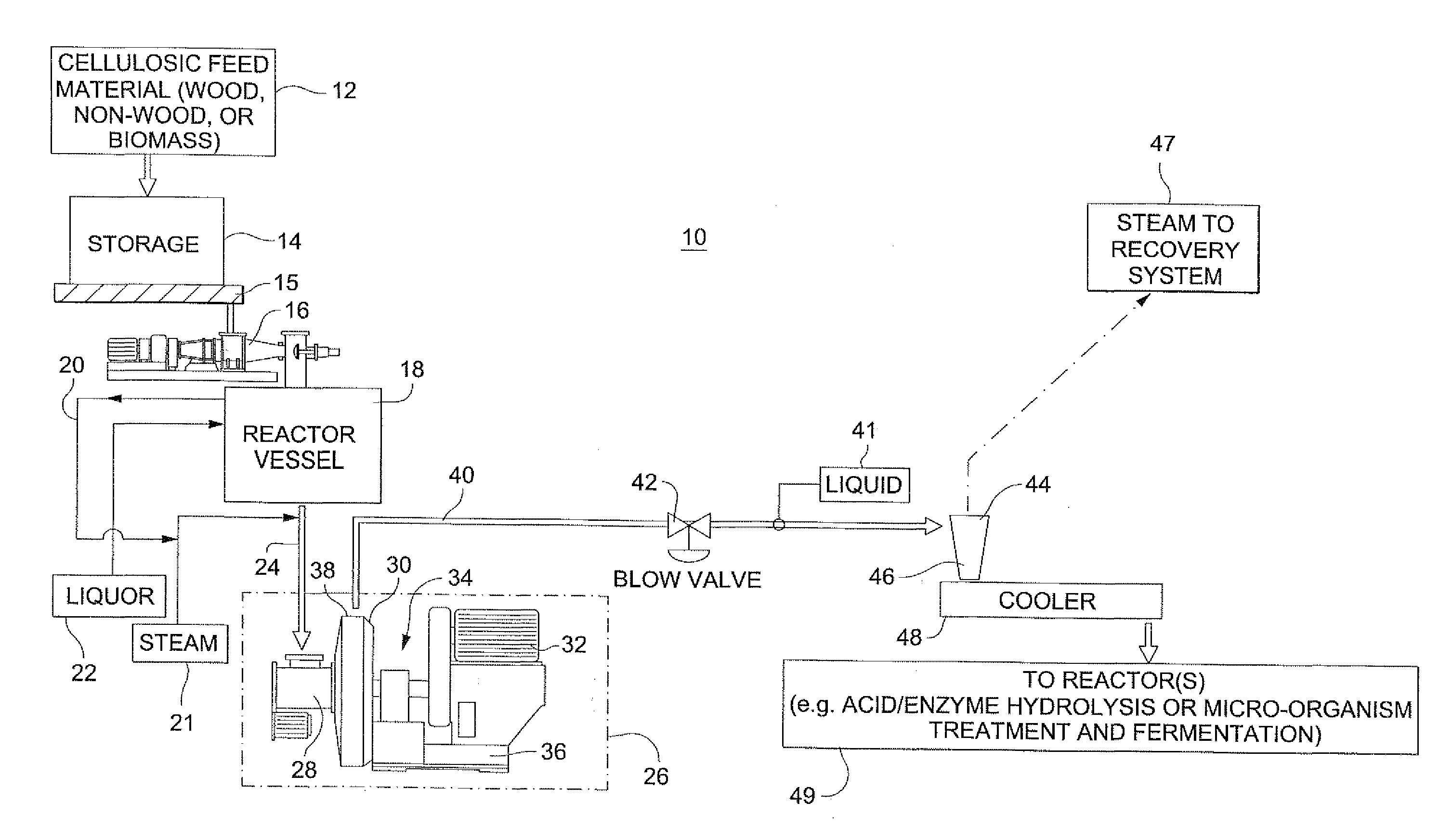

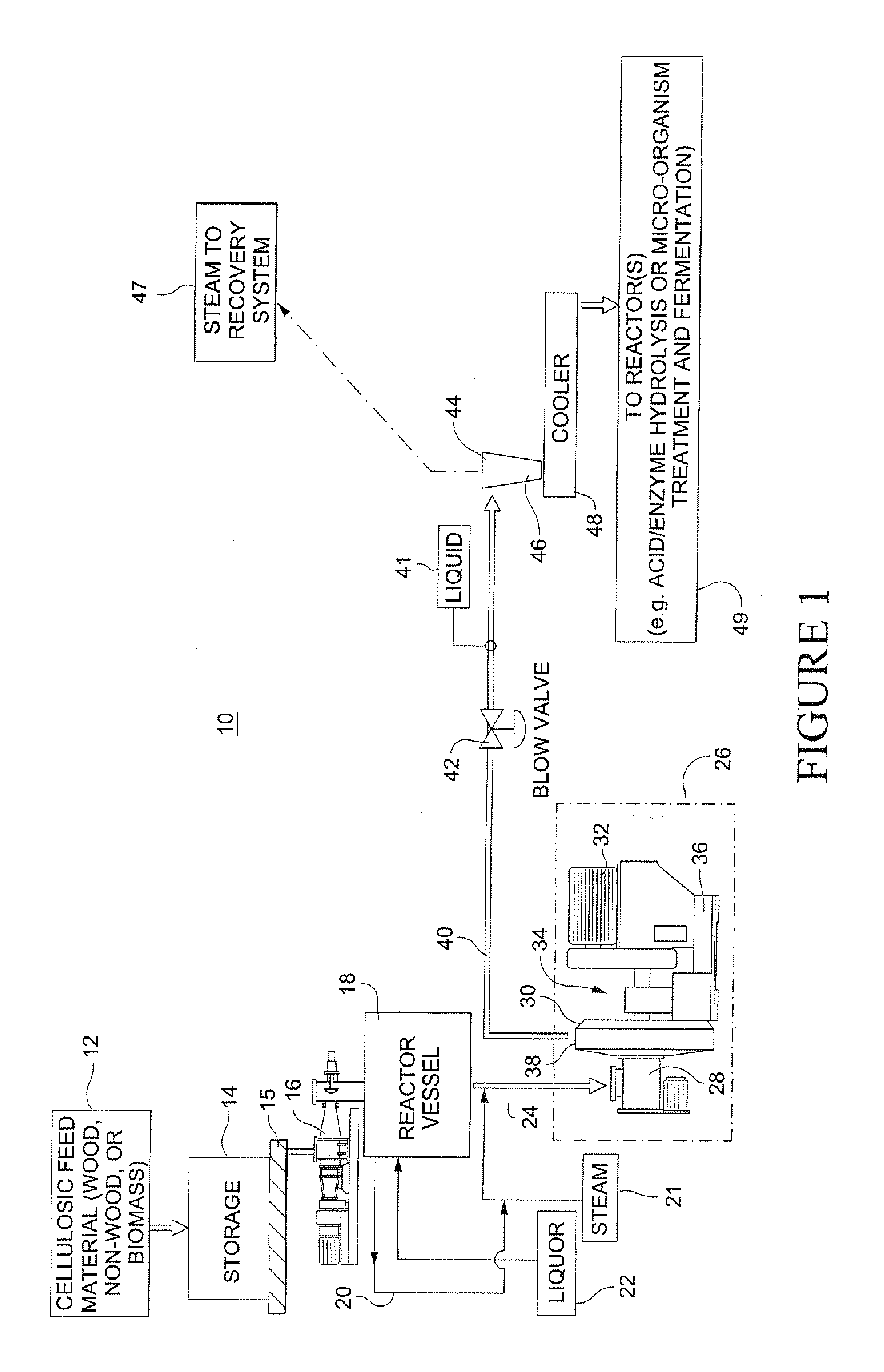

[0013]A high pressure discharge compressor has been developed to pressurize a cooked cellulosic biomass feed material stream so that the stream may be subjected to steam explosion pulping. The high pressure discharge compressor applies centrifugal force to increase the pressure of a feed material stream from a pressurized reactor vessel. The centrifugal force applied to the stream increases the pressure to, for example, at least 0.5-1 bar above the pressure inside the cooking reactor. The pressurized stream is discharged from the compressor to a conduit that leads to a blow valve, where the steam explosion converts the feed material to pulp.

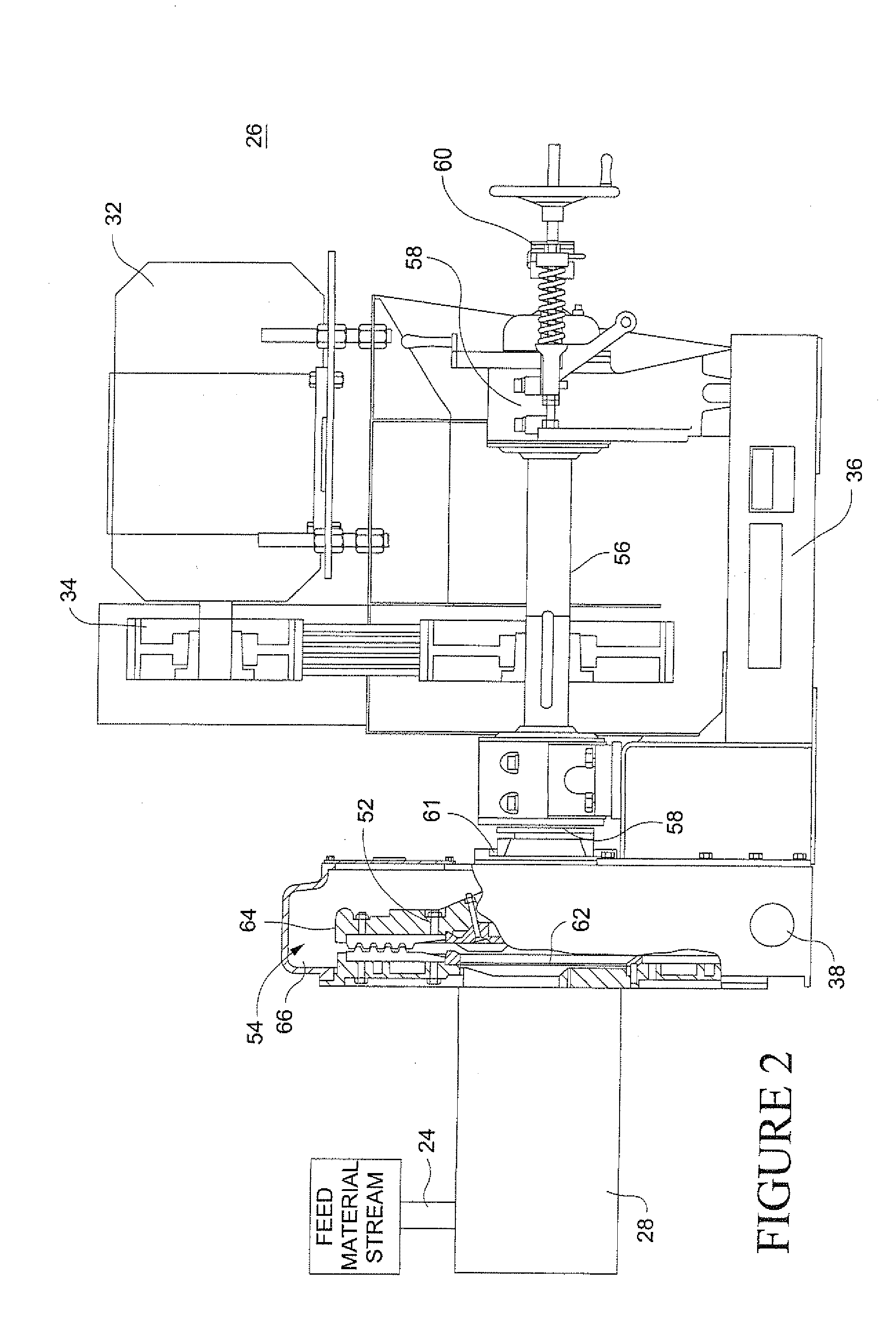

[0014]The high pressure discharge compressor may have a casing, rotating disc(s), drive motor, transmission and bearing, and maybe a front end screw that are similar to a conventional mechanical refiner, e.g., MDF refiner. The digester may have a scraper or a discharge conveyor (typically a screw) to feed the material to the compressor via a feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com