Sole Unit for Footwear and Footwear Incorporating Same

a technology of footwear and footwear, applied in the direction of shoes, top-pieces, heels, etc., can solve the problems of unforgiving structural support of the footwear upper, exaggerated and unnatural torsional traction with the ground, and complex and multi-directional foot movements during a foot strike (step)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

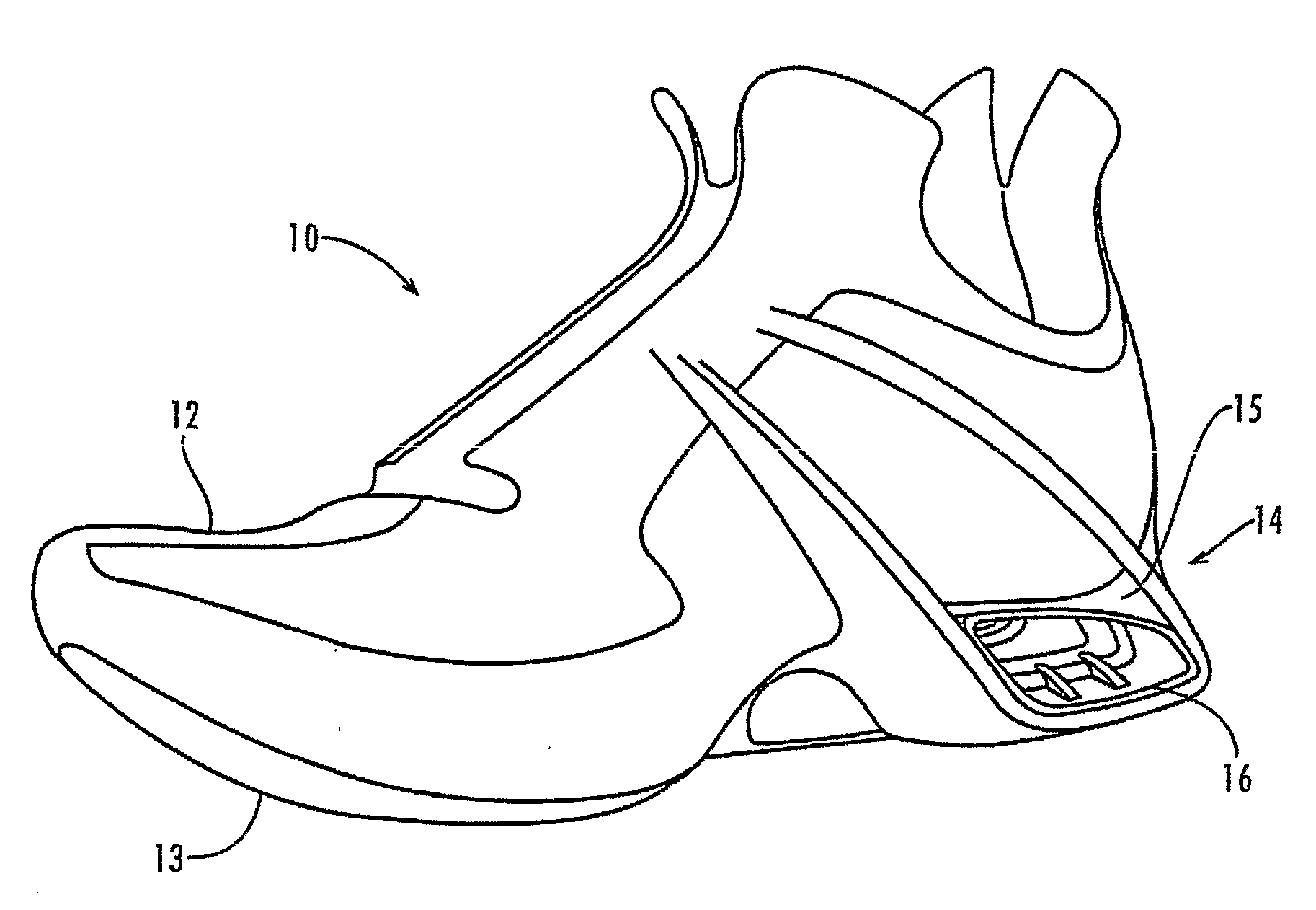

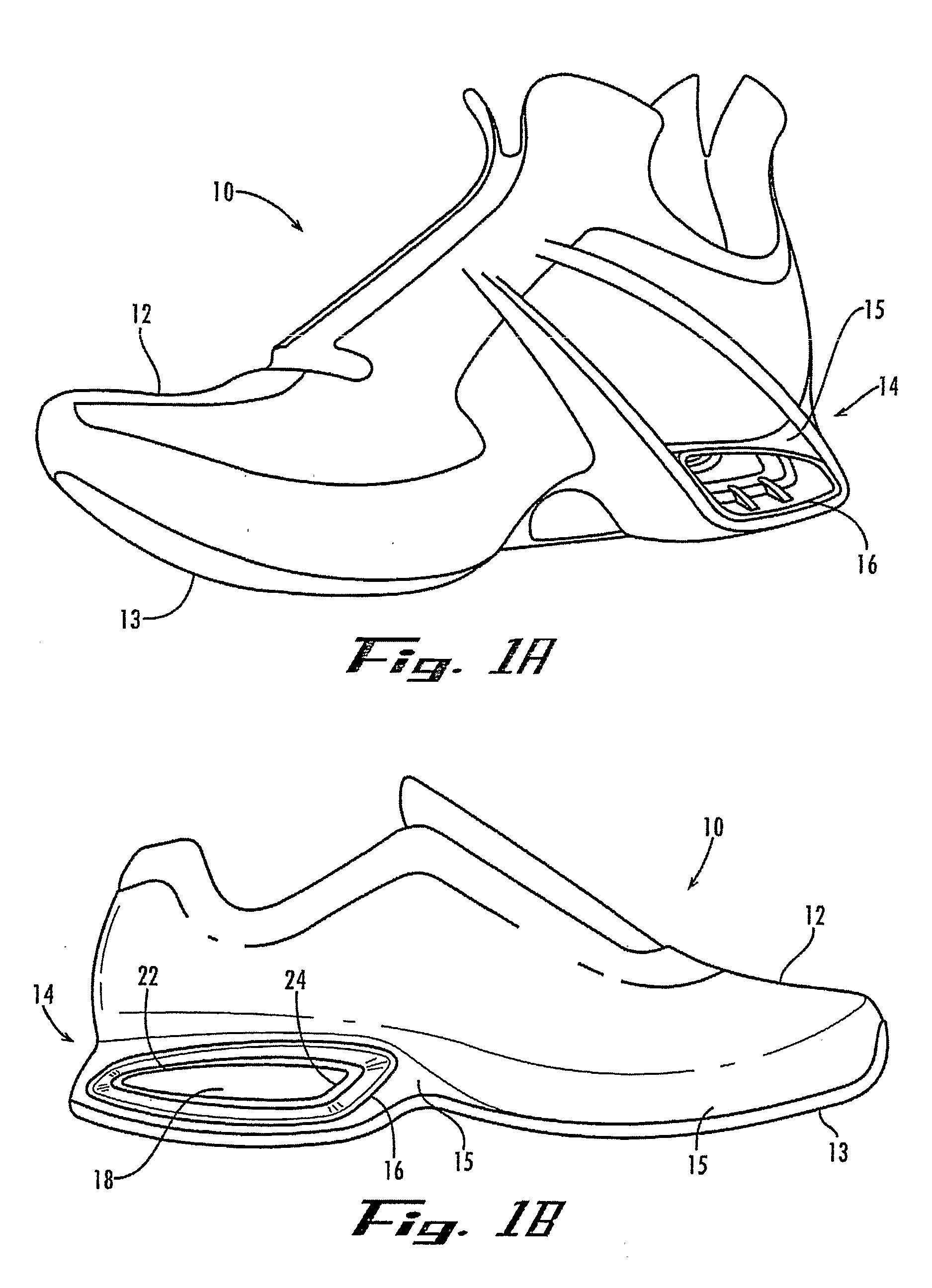

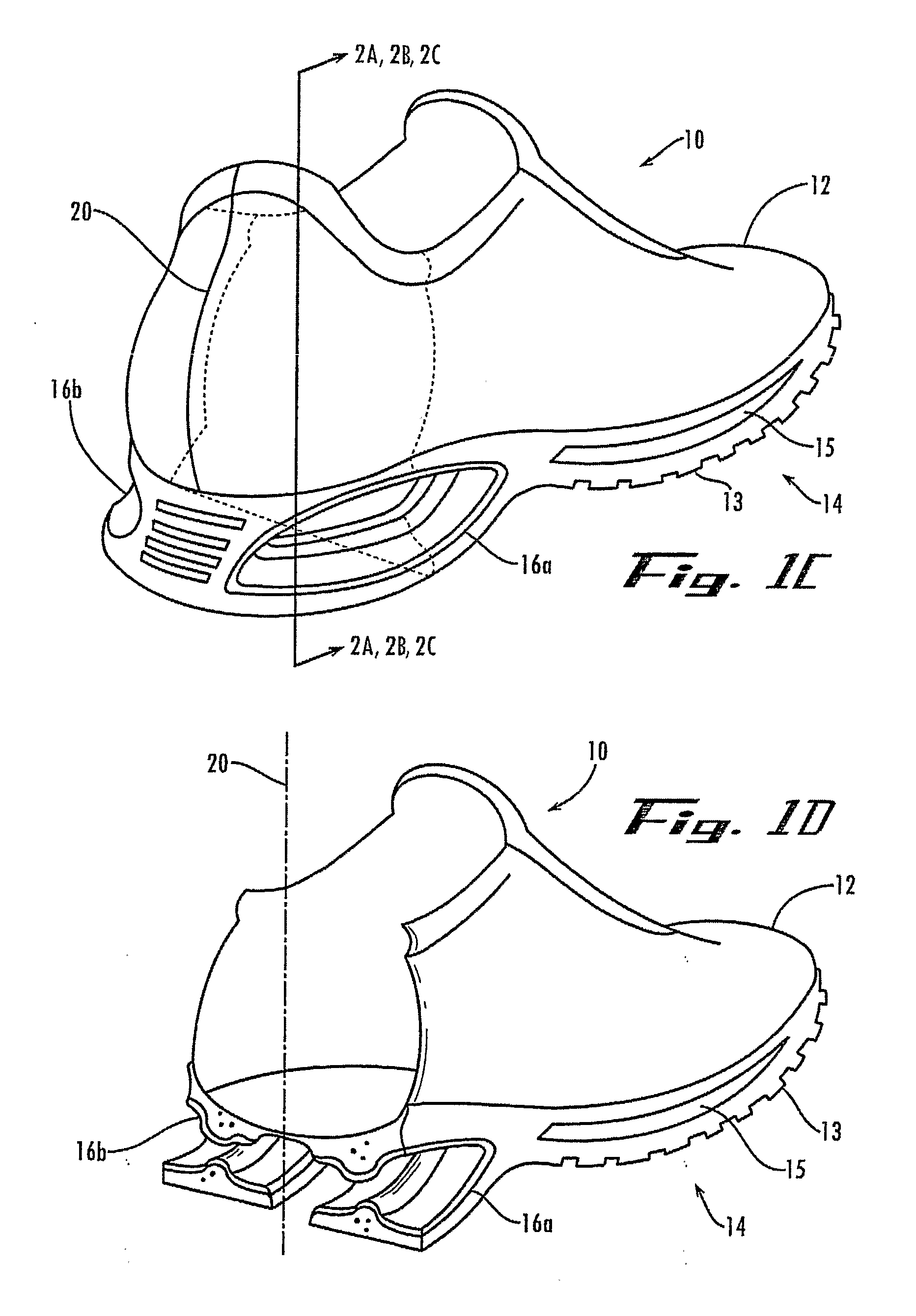

[0061]Referring to FIG. 1A and FIG. 1B, shoe 10 comprises an upper 12 and a sole unit 14. Sole unit 14 includes a forefoot section, midfoot section, and rearfoot (or heel) section. Sole unit 14 further includes a lateral half and a medial half. In the embodiment shown, sole unit 14 incorporates in its rearfoot section a three-dimensional progressive force-tuned spring unit 16. Sole unit 14 also includes an outsole 13 for ground contact and conventional midsole material 15 in the forefoot area as well as, optionally, the surfaces adjacent to spring 16. The spring unit is shown in the rearfoot; however, as will be discussed in more detail, it may be incorporated as one or more elements extending beneath the wearer's whole foot.

[0062]As used herewithin, “shoe” refers to footwear generally and includes shoes, sandals, boots, and other footwear articles. “Sole unit” generally may comprise a midsole for energy absorption and / or return; an outsole material for surface contact and abrasion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com