Marine windshield frame and method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

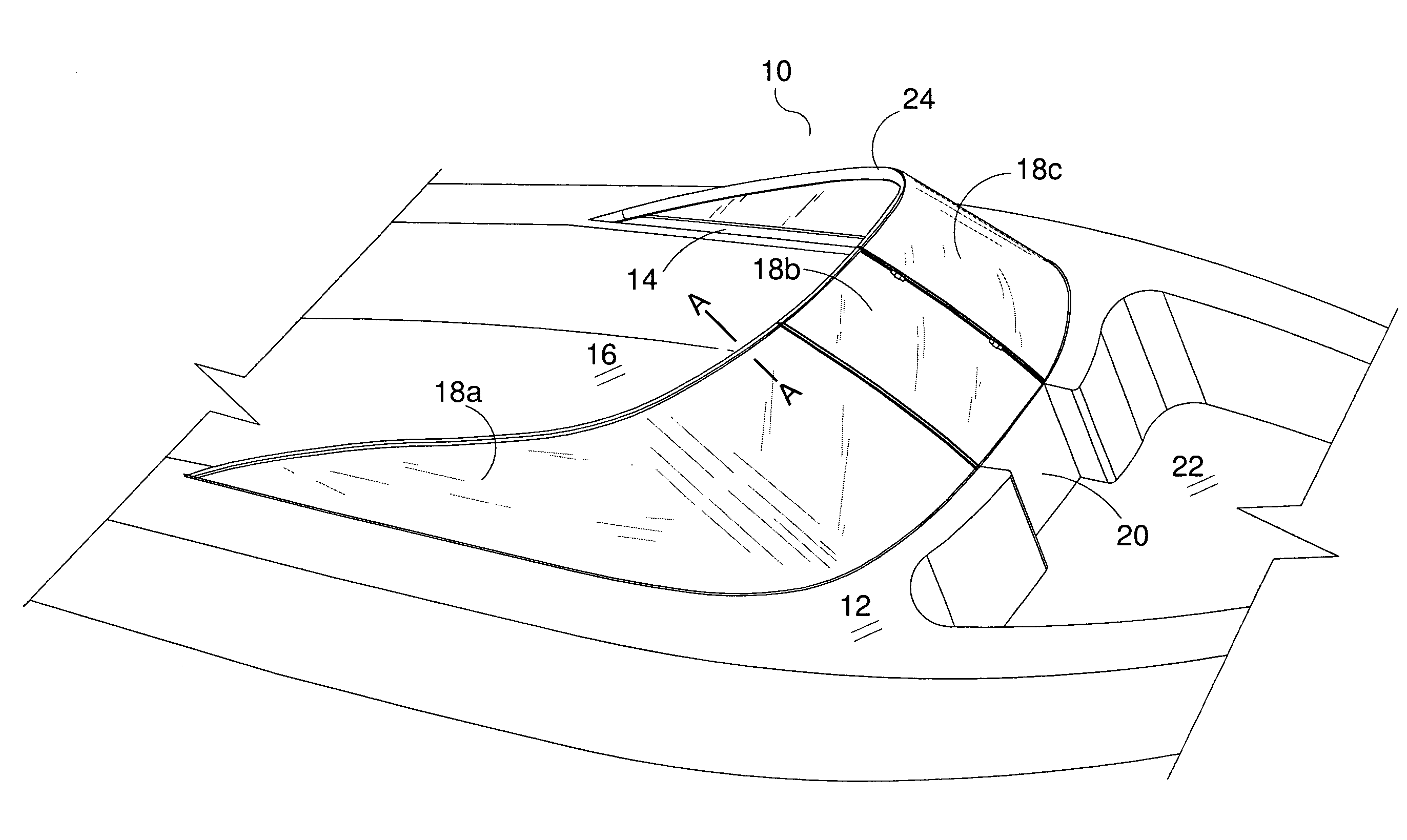

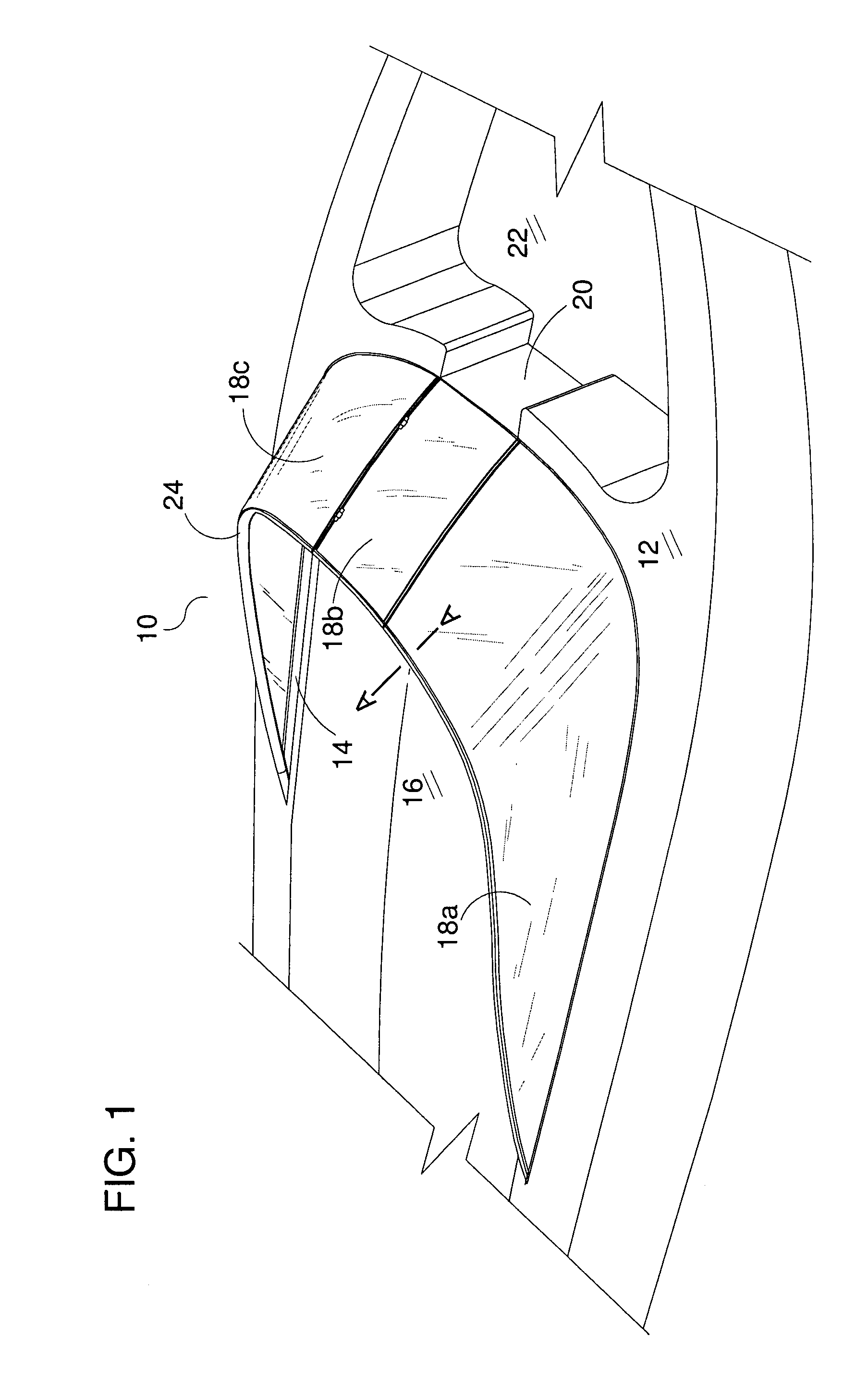

[0039]The marine windshield frame is generally referred to as 10 as shown in a perspective view in FIG. 1. A boat is shown in partial view where a deck 12 has windshield 10 mounted thereon deck 12, by means of windshield base frame rail 14. Windshield 10 is segmented, dramatically curved and swept back along the front sides of a cockpit area 16.

[0040]Windshield 10 includes windshield glass 18, where windshield glass 18 includes peripheral sections 18a, 18b, and 18c. Windshield section 18b is attached to a hatch door 20, where hatch 20 allows access to the front deck seating area 22. On top of glass sections 18a, 18b and 18c is longitudinally extending top windshield frame rail 24.

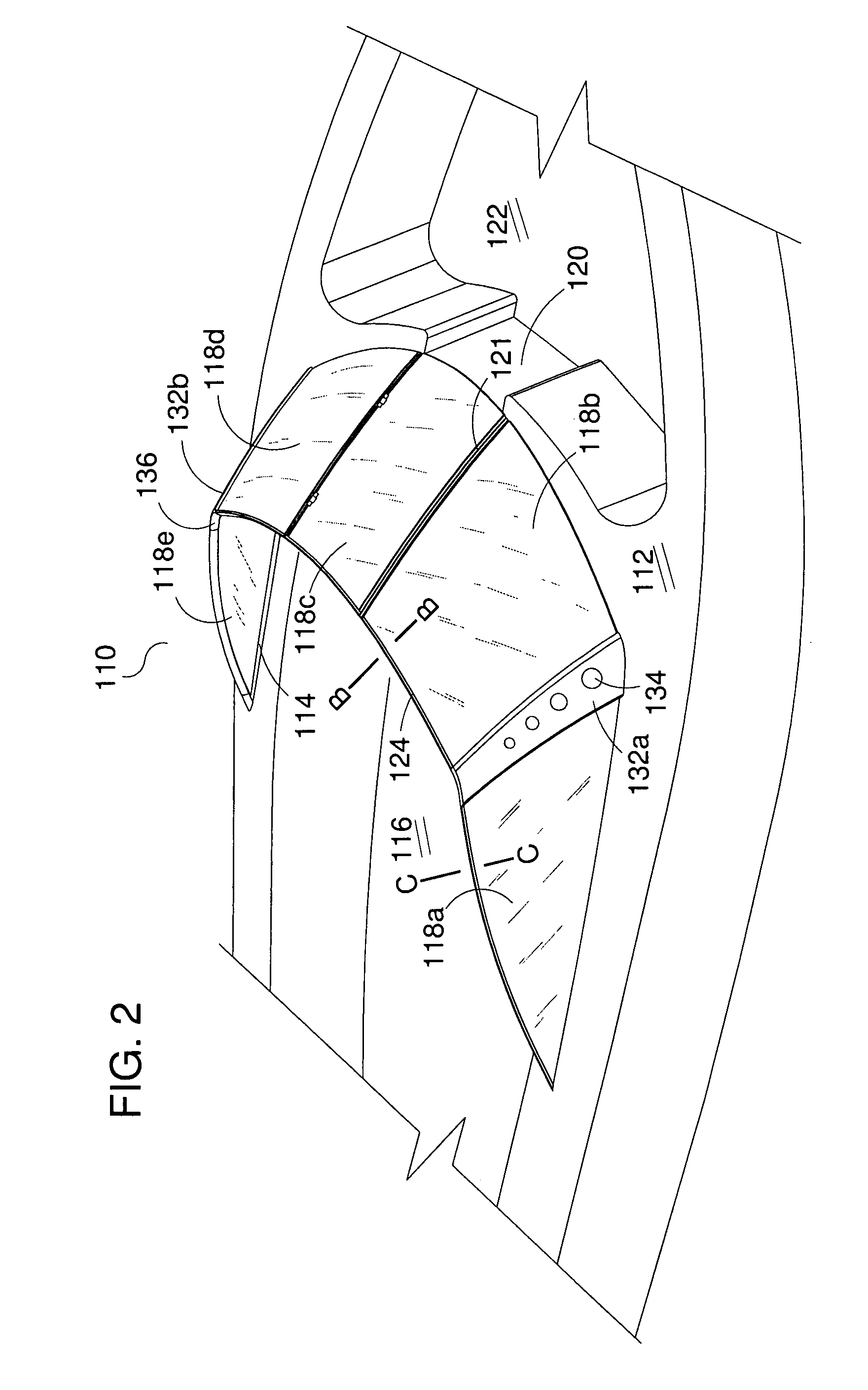

[0041]Alternate marine windshield frame as shown in a perspective view in FIG. 2, is generally referred to as 110. A boat is shown in partial view where a deck 112 has windshield 110 mounted thereon. Windshield 110 is segmented, gently curved and swept back along the front sides of a cockpit area 116.

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com