Induction Cook Top with Heat Management System

a technology of heat management system and cook top, which is applied in the direction of induction heating, electric/magnetic/electromagnetic heating, electrical apparatus, etc., can solve the problems of component failure, increase the temperature inside, and existing cooling systems do not account for the temperature of the incoming air, so as to improve the air flow through the system, improve the efficiency of heating, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

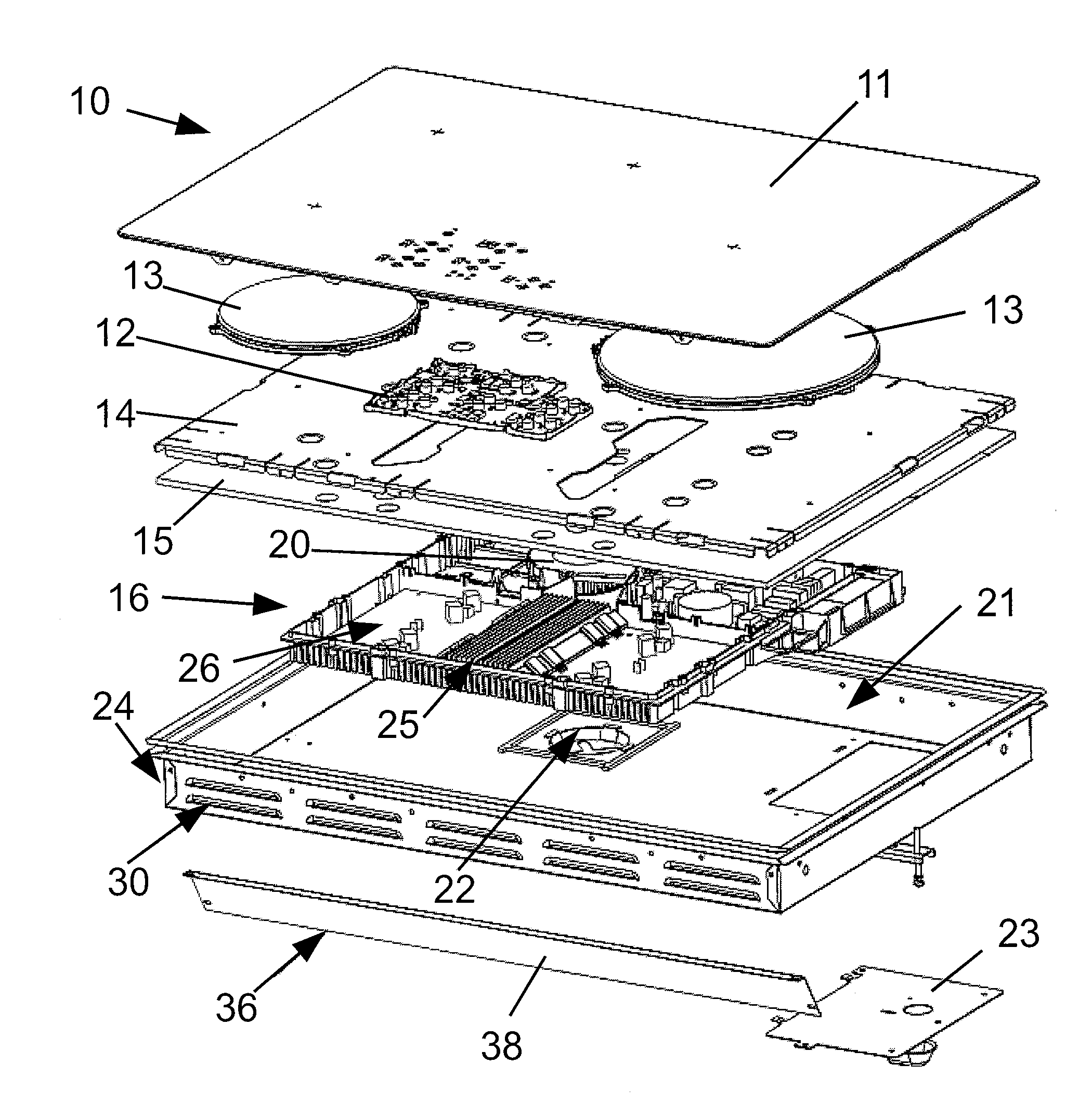

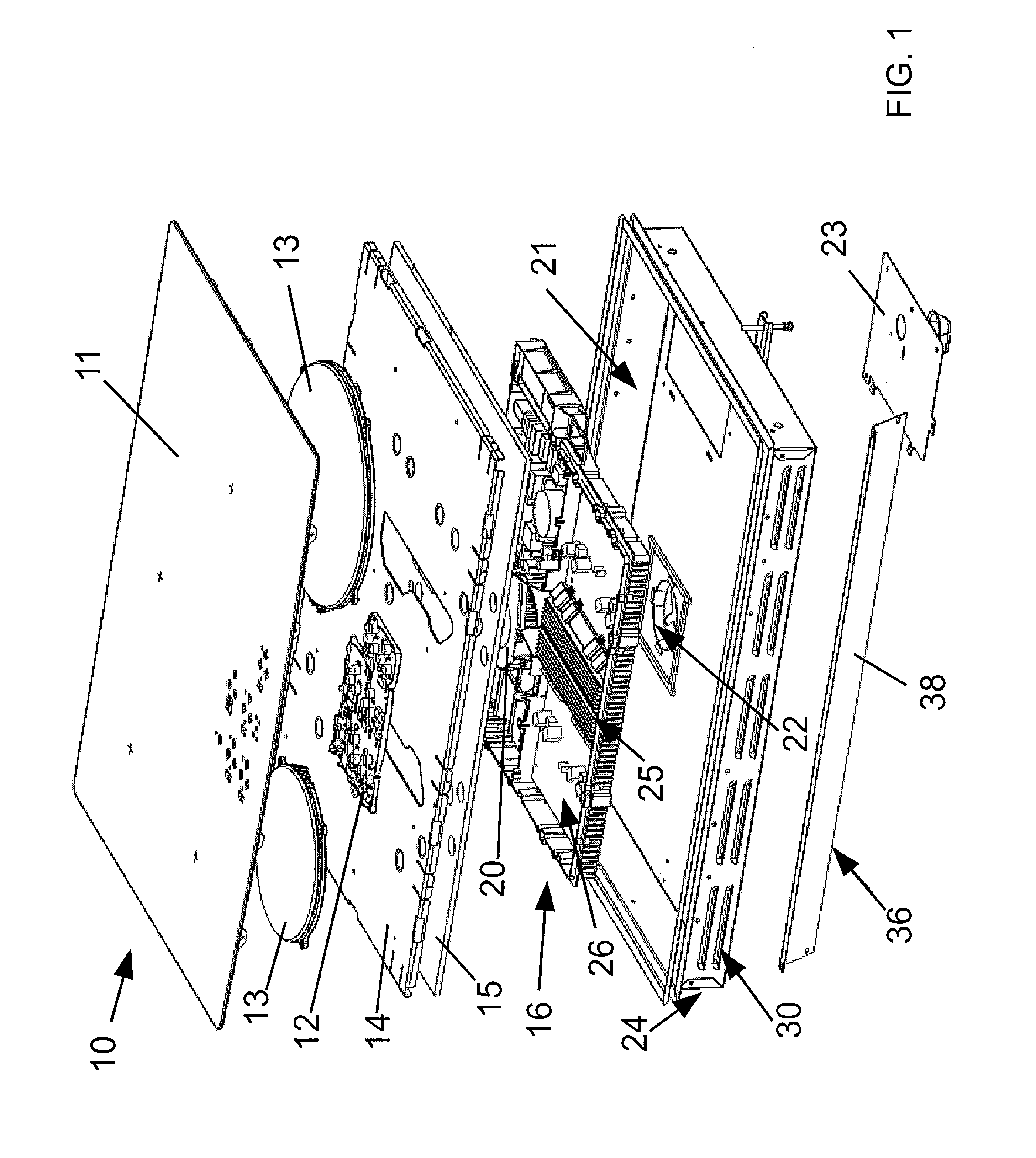

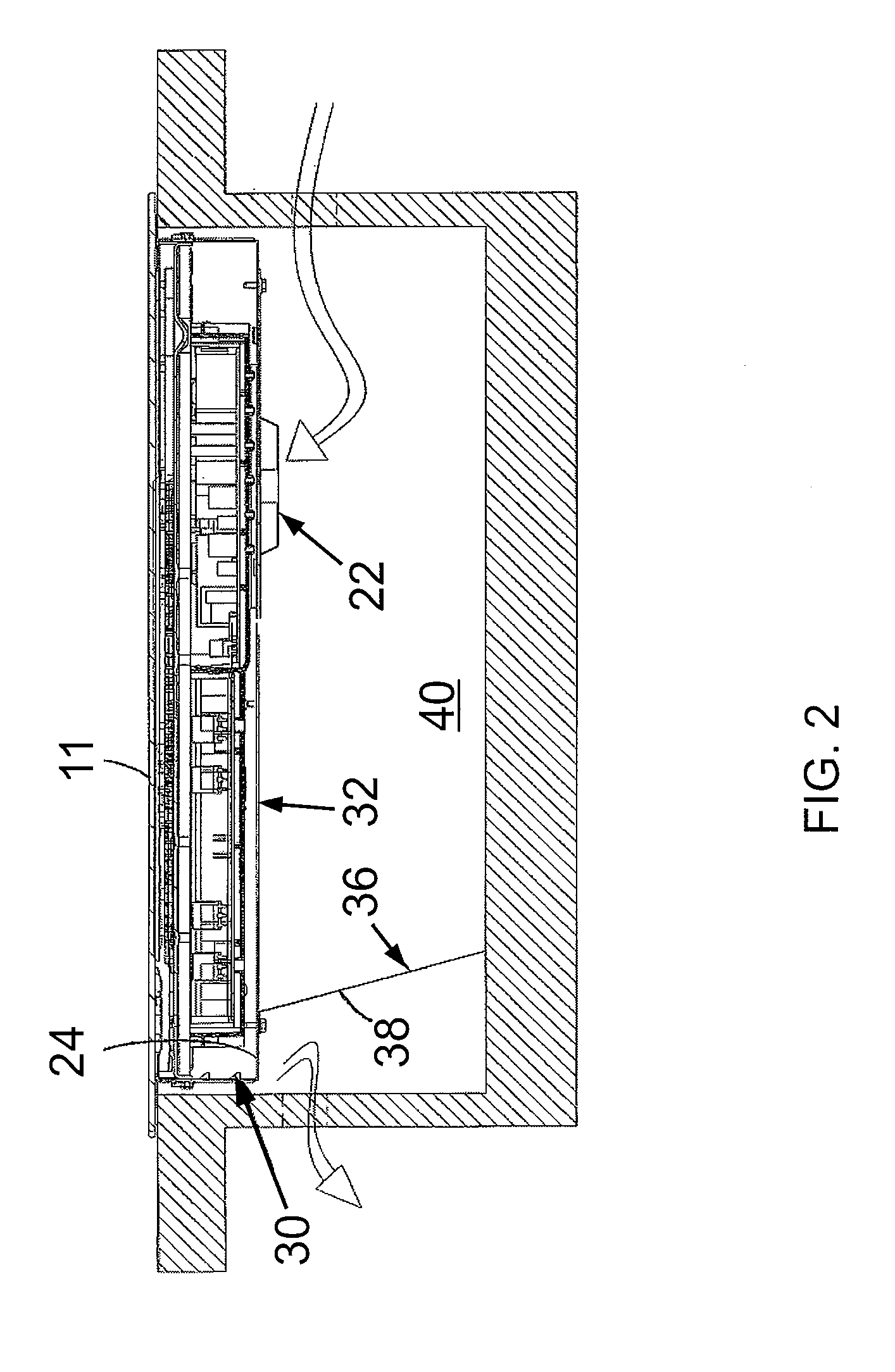

[0035]The present invention and the various features and advantageous details thereof are explained more fully with reference to the non-limiting embodiments described in detail in the following description.

[0036]Note that the detailed description that follows the drawings, which are used, do not show all the details of every product described, but only certain features of the invention that aid in describing the invention. One skilled in the art will see the benefits of this new invention and know of all the other methods of construction and design.

[0037]1. System Overview

[0038]The present invention relates to an indoor or outdoor induction cook top having a heat management system and system heat control. Briefly, this is accomplished by providing an induction cook top with the a system to control and efficiently remove the heat generated by the electronic controller, mechanical controls, and the induction generators of the cook top while also providing precise temperature control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com