Feed module including an envelope closure device that retains water

a technology of envelope closure and feed module, which is applied in the field of mail handling, can solve the problems of serious consequences of smudging the printing of the postal imprint, and the simpleness of the envelope flap closure system, and achieve the effect of reducing the risk of smudging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

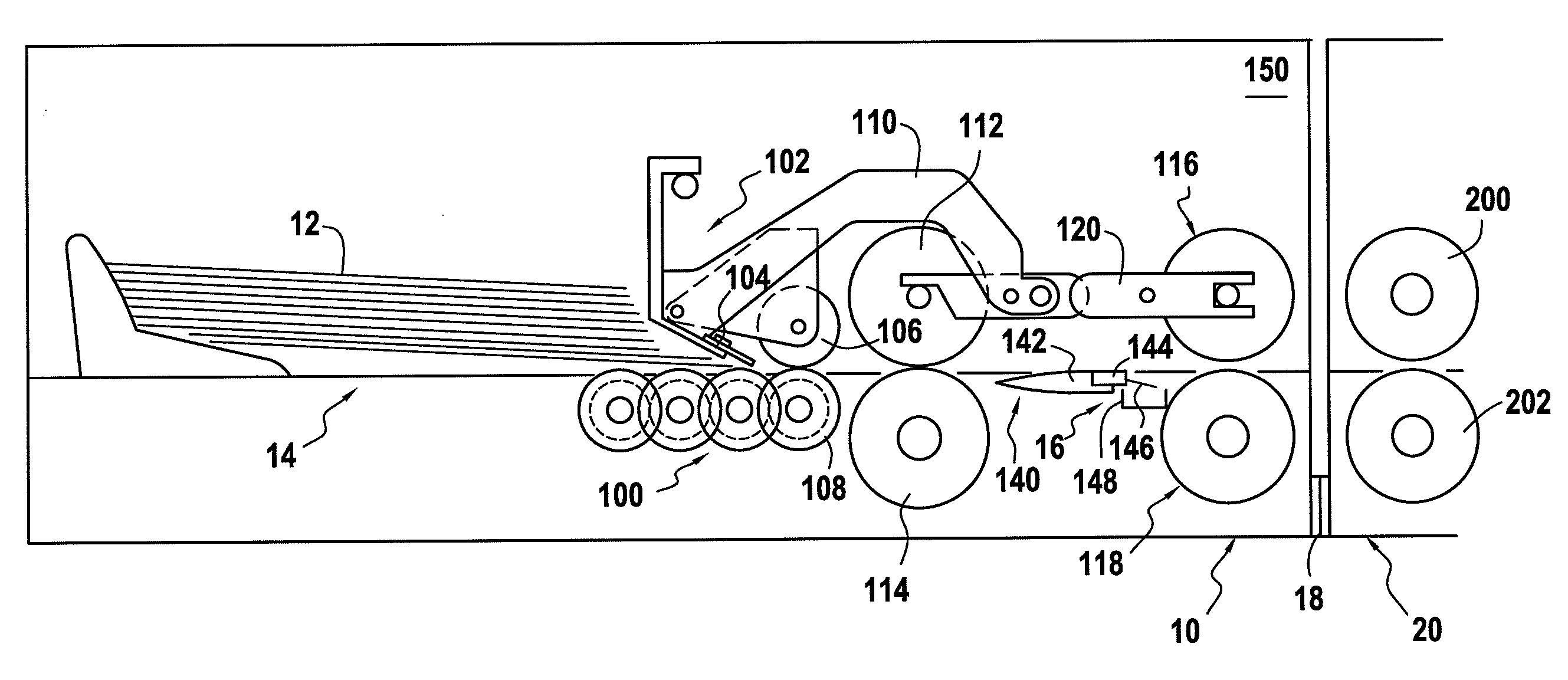

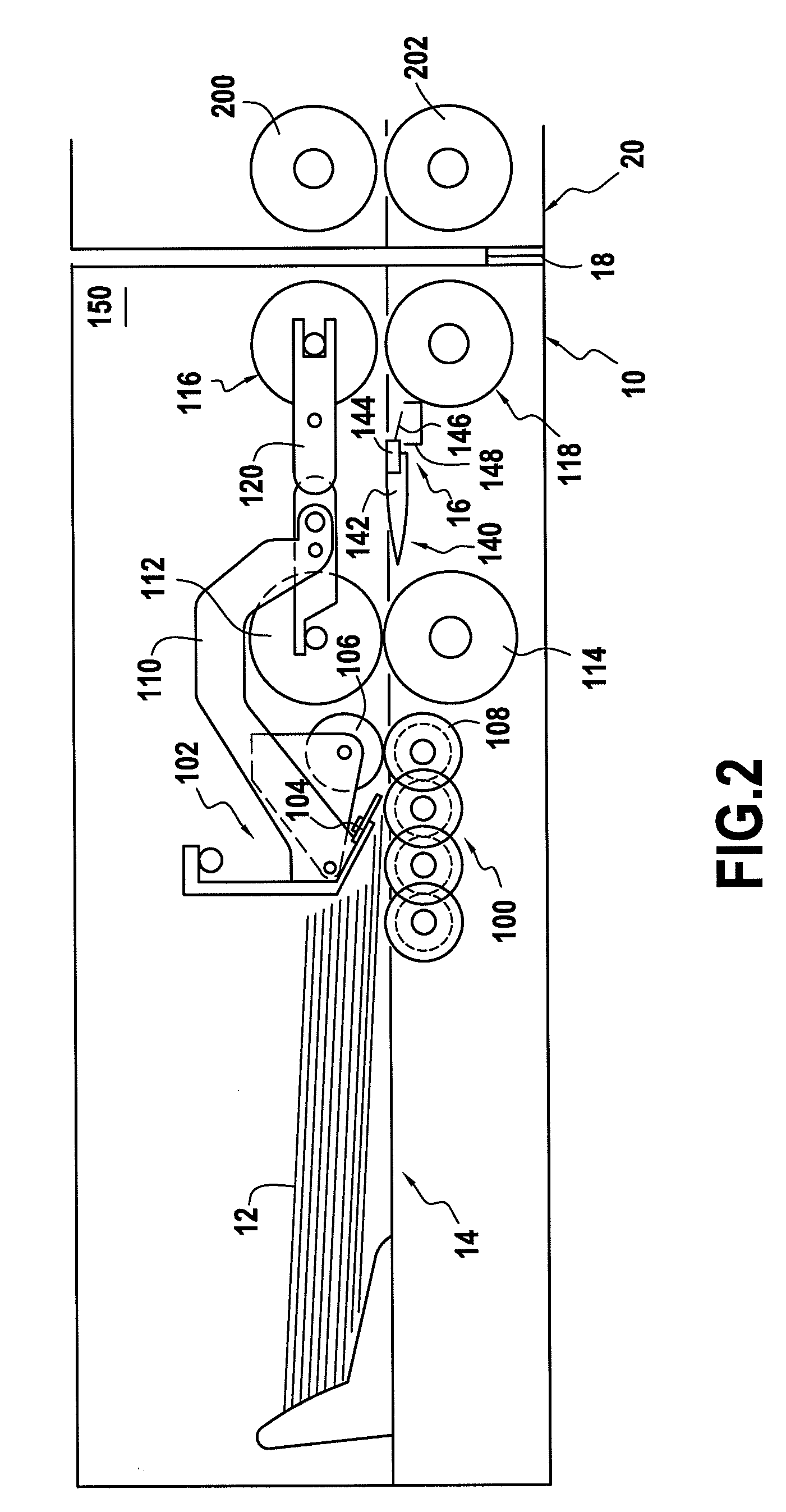

[0019]FIG. 2 is a highly diagrammatic view of a prior art feed module 10 for feeding envelopes 12 into a mail handling machine. That feed module comprises a series 100 of drive rollers that direct the envelope 12 (as slightly inclined and jogged from behind on a feed plate 14 provided with a stack of such envelopes) towards and under separator means 102 conventionally comprising a guide 104 and superposed selector rollers 106, 108 for selecting the envelopes one-by-one. Conveyor means comprising in particular a presser assembly 110 and superposed drive rollers 112, 114 convey each selected envelope towards moistener means 16 for moistening the envelope flaps. In the example shown, and as is known, such a moistener device comprises a separator 140 having a stationary portion 142 secured to the body of the feed, and a hinged portion 144 provided with a brush 146 whose bristles, directly in contact with a moistener reservoir 148 in the absence of envelopes then comes to moisten the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com