Adapter for cutting tooth

a technology for adapters and teeth, applied in soil-shifting machines/dredgers, construction, etc., can solve the problems of mounting blocks, damage to cutting teeth, and relatively expensive replacement of teeth, and achieve the effect of facilitating replacement and facilitating replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

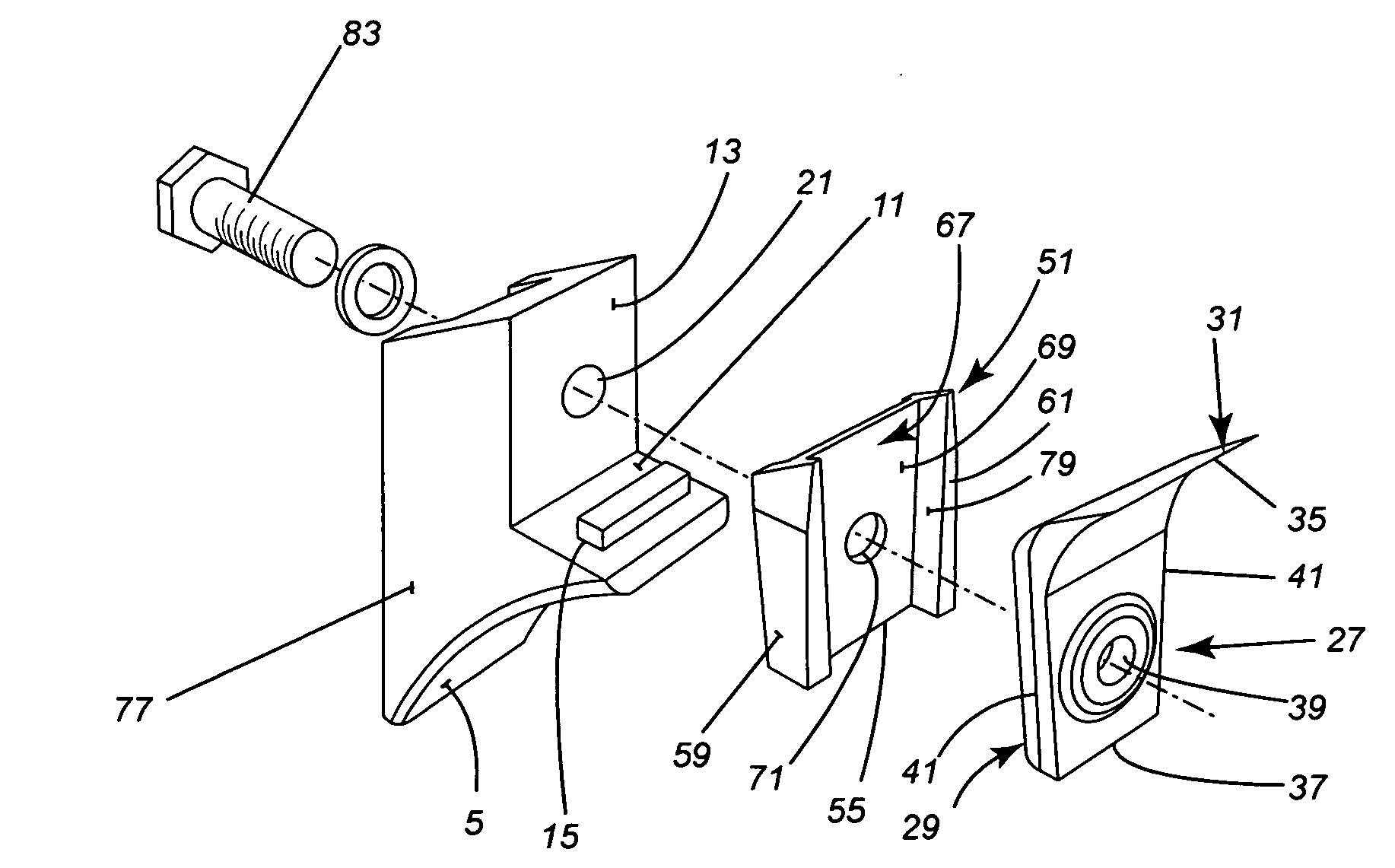

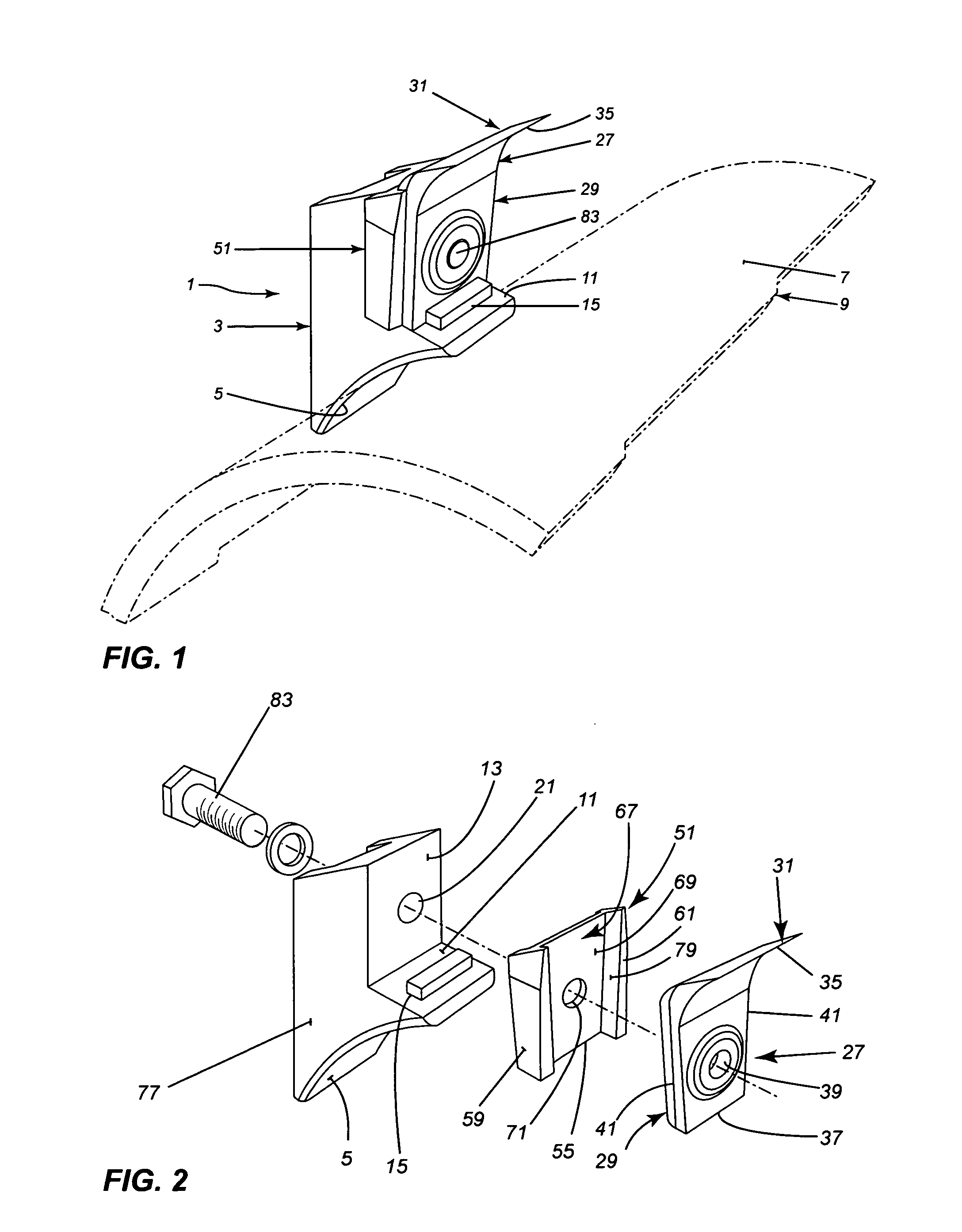

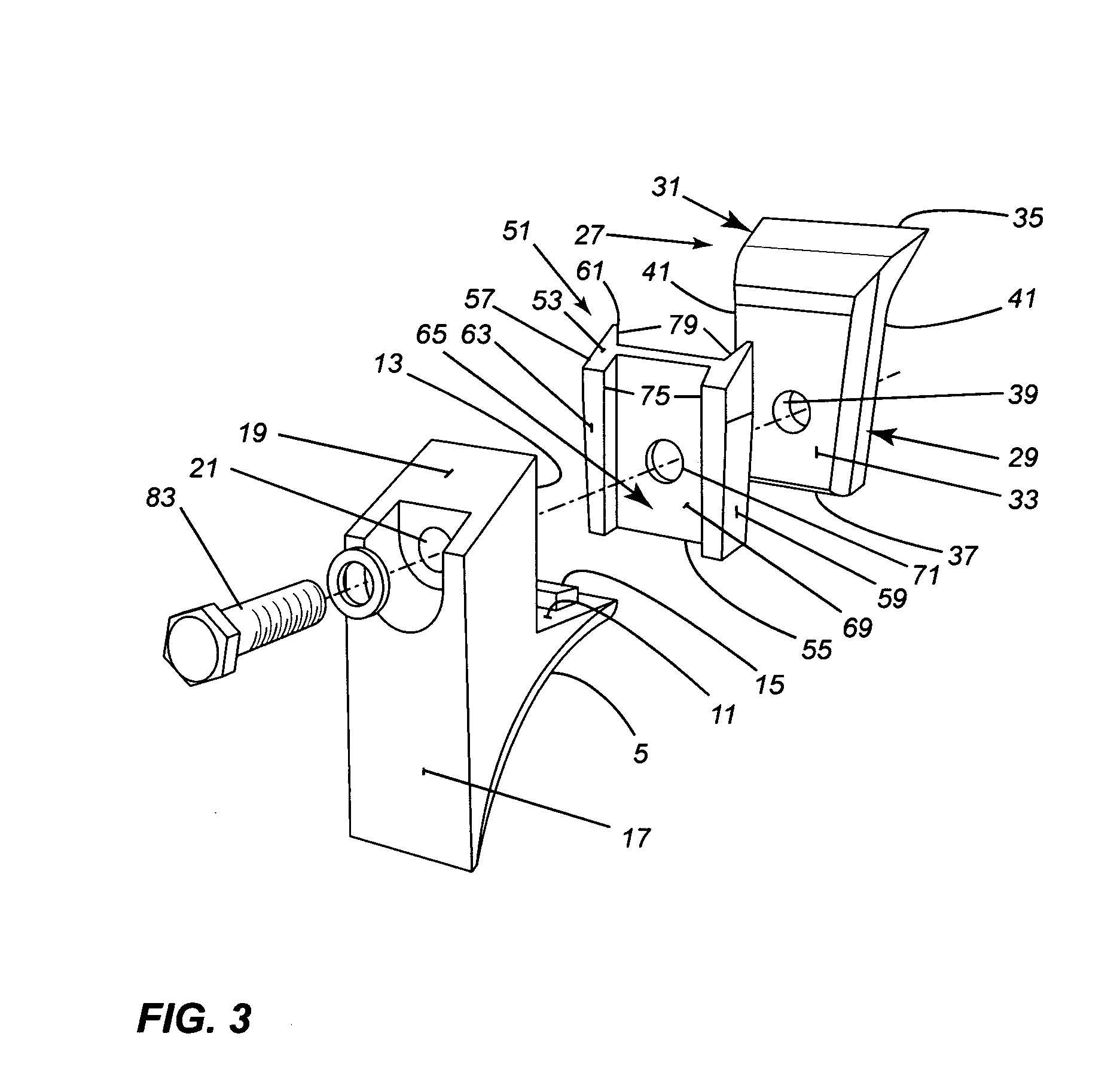

[0016]The mounting assembly 1 of the present invention, as shown in FIGS. 1, 2 and 3, includes a mounting block 3 having a bottom side 5, slightly concave, by means of which it is attached to the surface 7 of a cylindrical, rotatable, cutter head 9. The mounting block 3 is attached, usually by welding, to the surface 7 to be transverse to the longitudinal, rotational axis of the cylindrical head 9. The mounting block 3 has a step 11 just above the front of the bottom side 5 and a front side 13 extending up from the step 11. A stop rib 15 can extend up from the step 11, spaced from the front side 13 and parallel to it. The block has a back side 17 extending up from the rear of the bottom side 5. The back side 17 can be parallel to the front side 13. A top side 19, which angles upwardly, joins the top of back side 17 to the top of the front side 13. A bolt hole 21 extends through the block from the back side 17 to about the center of the front side 13. When the block 3 is mounted on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com