Hollow fiber membrane module, and a manufacturing method therefor, and housing for hollow fiber membrane module

a technology manufacturing method, which is applied in the direction of light beam reproducing, instruments, transportation and packaging, etc., can solve the problems of low thickness of hollow fiber membrane module per unit volume, restricted longitudinal direction of hollow fiber membrane bundle deflection in the housing, and high contaminated water hair accumulation, etc., to achieve easy pouring of fixing resin into the resin pouring section, the effect of reducing the consumed amount of the necessary fixing resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079]Here, the present invention is further explained in detail.

First Aspect of the Hollow Fiber Membrane Module

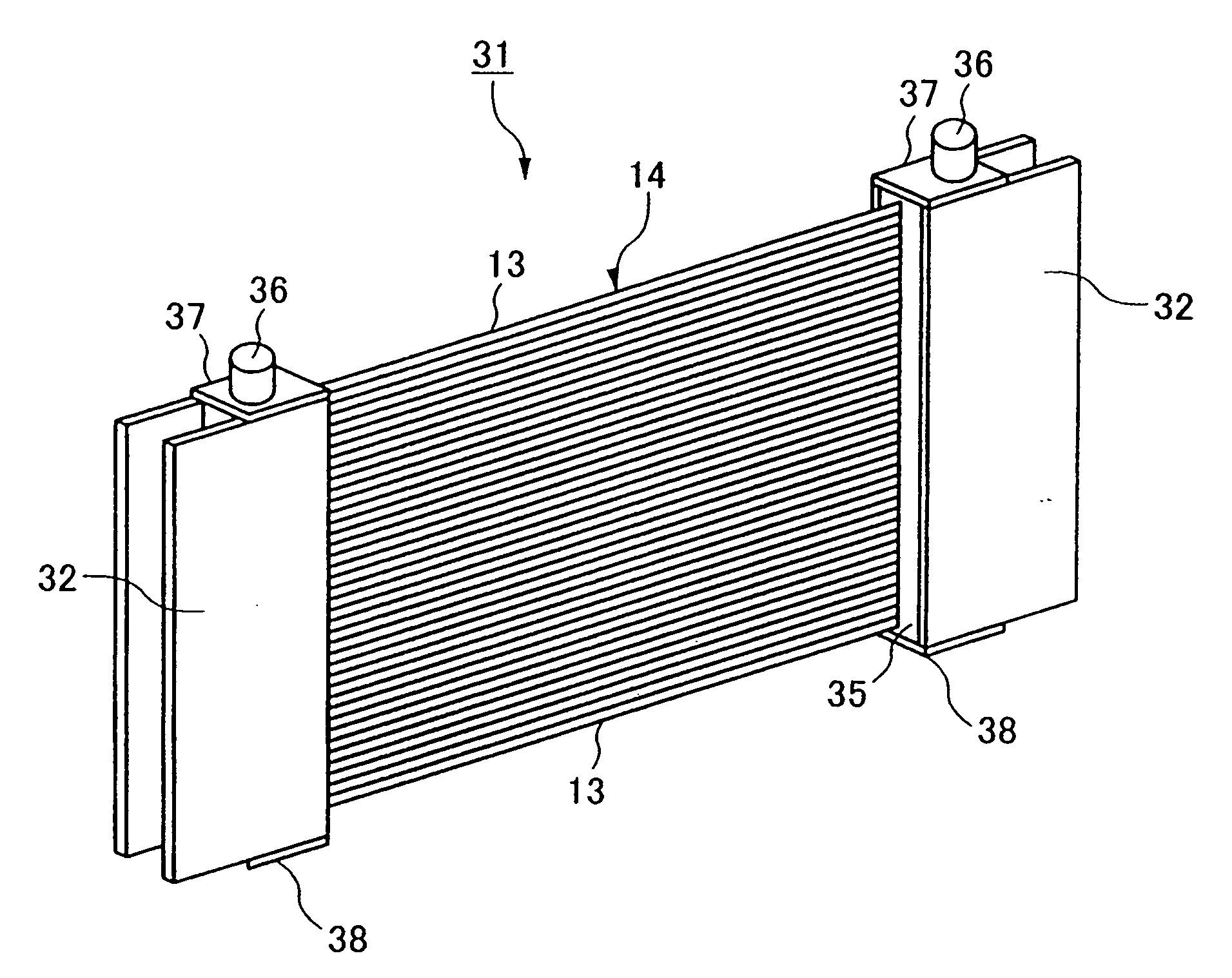

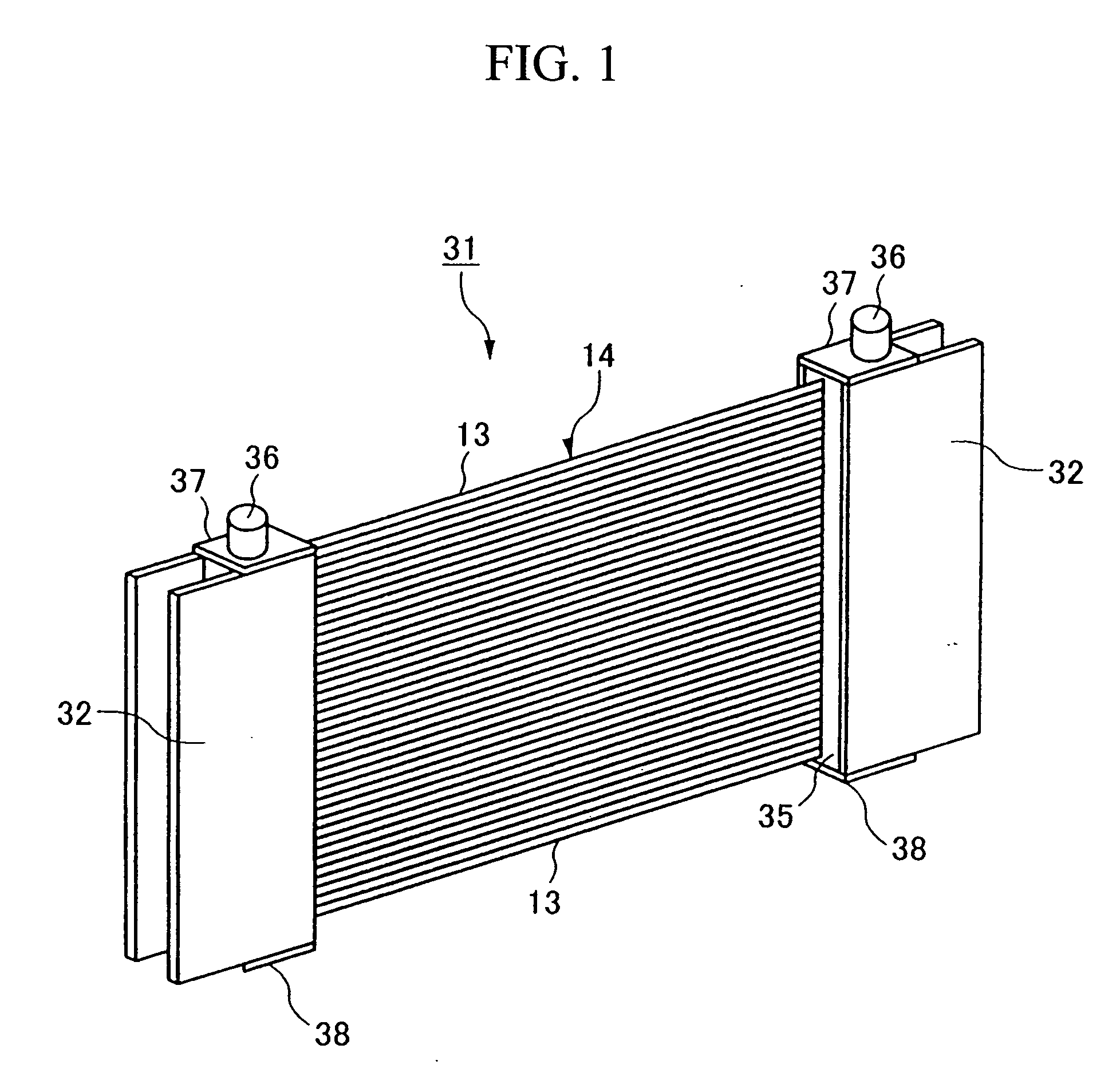

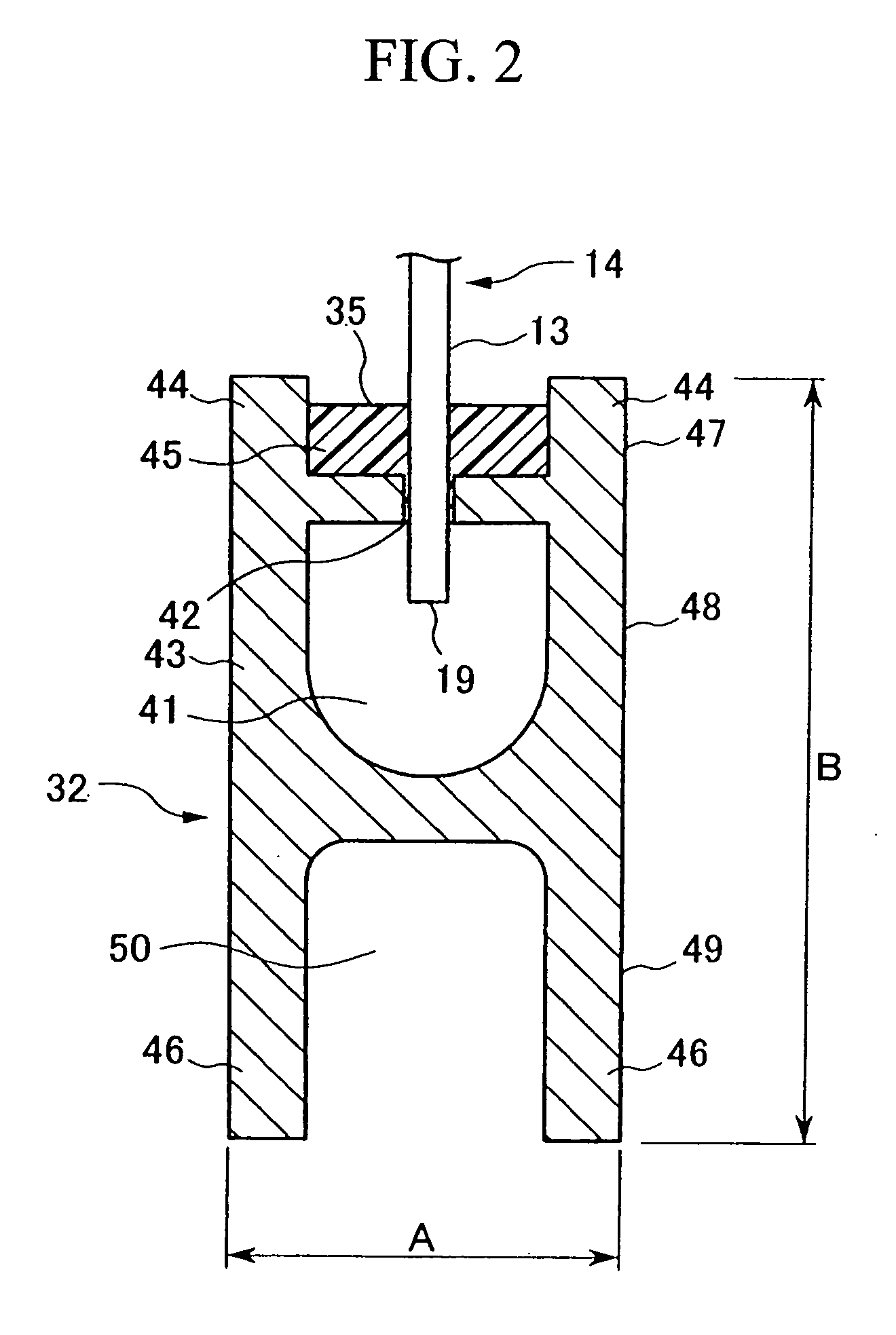

[0080]FIG. 1 is a perspective view showing an example for a hollow fiber membrane module according to the present invention. FIG. 2 is a cross section in the housing in the hollow fiber membrane module shown in FIG. 1.

[0081]A hollow fiber membrane module 31 approximately comprises a pair of housings 32, a hollow fiber membrane bundle 14 in which a plurality of hollow fiber membranes 13 are bundled as a sheet, an end cap 37 which is attached on an end of the housing 32 having a processed-water exit 36, and an end cap 38 which is attached on another end of the housing 32 without a processed-water exit. Here, the hollow fiber membrane bundle 14 is fixed on the housing 32 by the fixing resin 35 under condition that the hollow fiber membrane bundle 14 is inserted in the housing 32 and an opening end section 19 in the hollow fiber membranes 19 is maintained open.

[0082]The housi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com