Mold shave apparatus and injection molded soldering process

a technology of injection molding and moulding, which is applied in the direction of metal working equipment, mold cavities, mold shave apparatus, etc., can solve the problems of inability to remove solder or alloys at room temperature, formation of empty or inadequate mold cavities, adversely affecting the integrity of any electronic device, etc., to facilitate the shaving of excess solder volume, adversely affecting the solder volume, and rapid operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

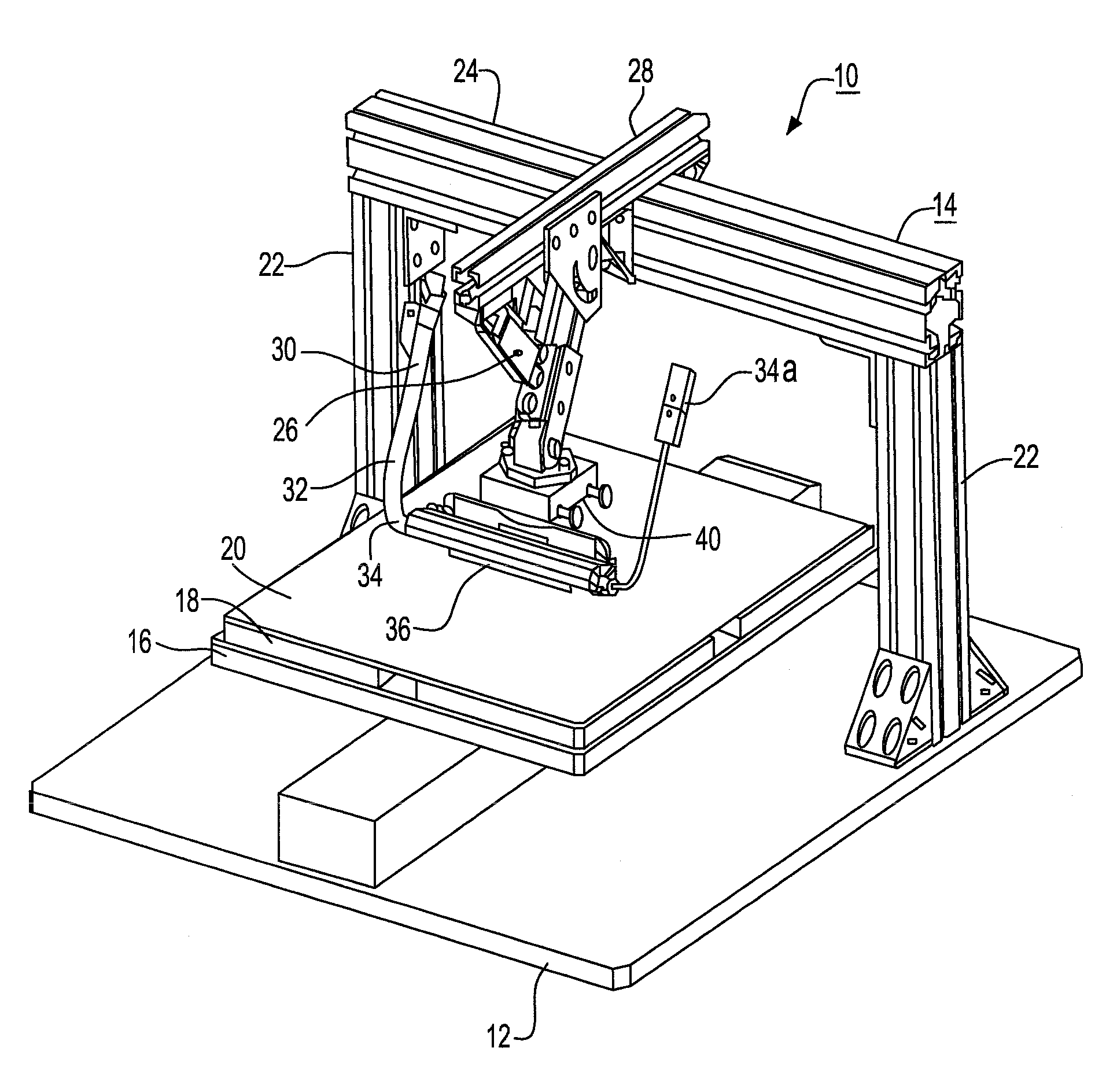

[0014]Referring to the shaving apparatus 10, there is disclosed a plate-like bottom support member 12 that has an upright bridge frame structure 14 beneath which there is located a movable table 16 adapted to be displaced in both x and y directions along the bottom support member 12 through the operation of a suitable operating and conveying structure (not shown).

[0015]Supported on the movable table 16 is a vacuum table 18, which enables the retention thereon of a large-sized mold plate 20 with a surface having a multiplicity of cavities or small holes (not shown) formed therein; each of which is adapted to be filled with a quantity of molten solder possessed of a precise volume of (C4) bumps, which are to be transferred to suitable wafer pads (not shown). As indicated, the mold plate 20 may be constituted of a borosilicate glass plate having the cavities etched therein, which represent the wafer (C4) pad locations and with cavity quantities ranging of from 100,000 to an excess of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com