Bidet assembly for toilets

a technology forbidets and toilets, applied in baths, physical therapy, construction, etc., can solve the problems of requiring additional floor space forbidets, prone to water splashing, high manufacturing costs, etc., and achieves the effect of convenient installation, preventing water splashing out, and cleaning of user's private parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

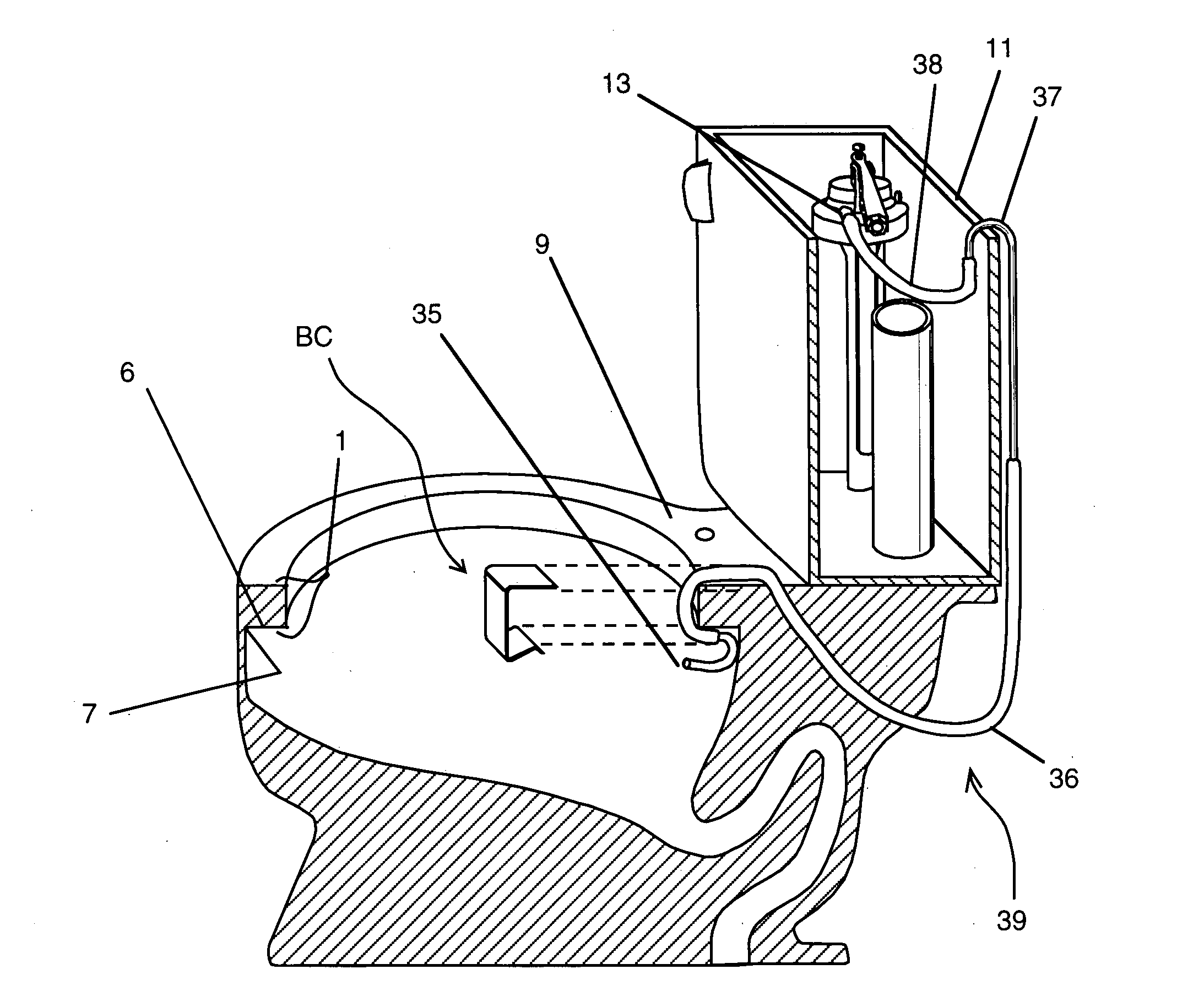

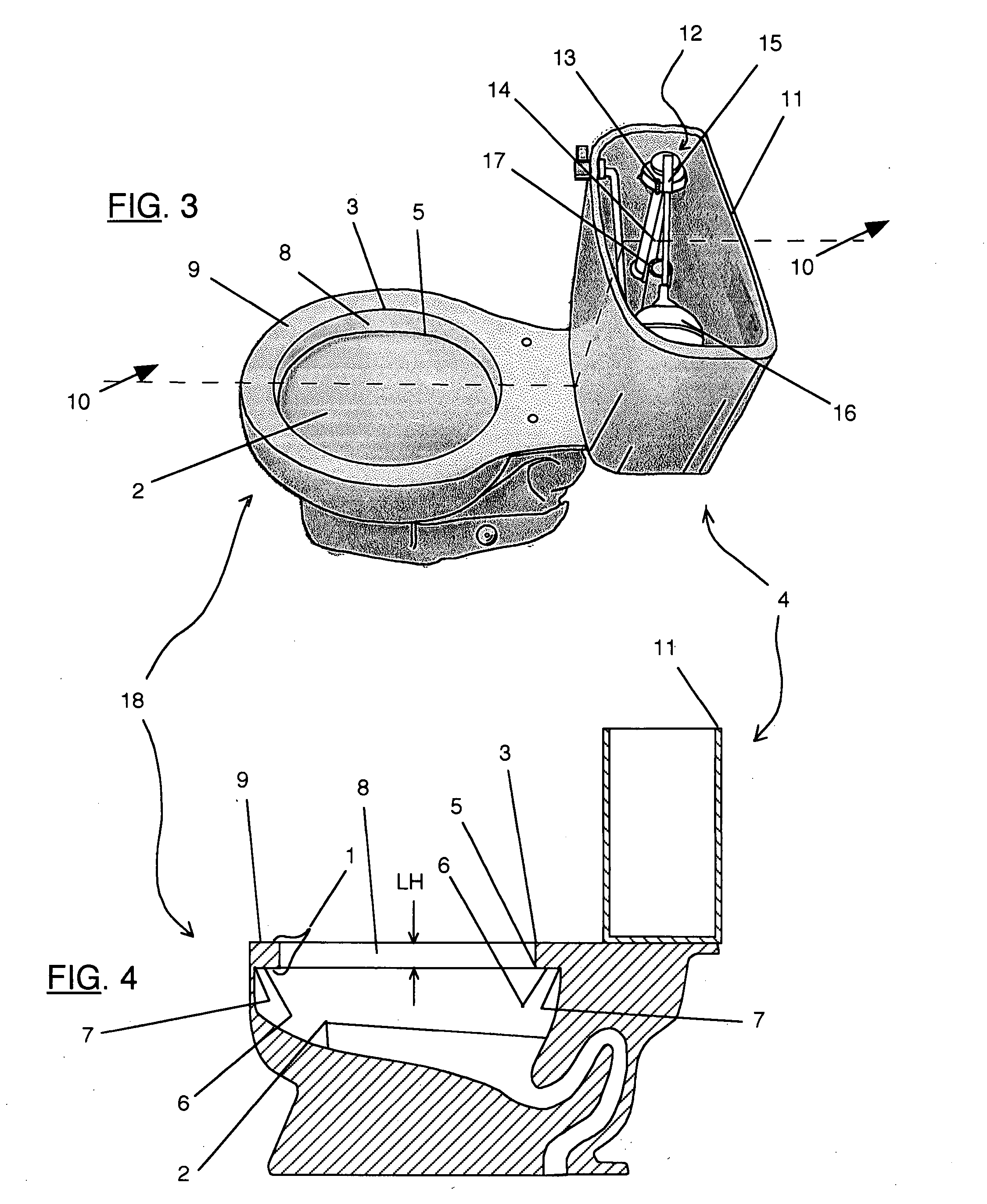

Method used

Image

Examples

example 1

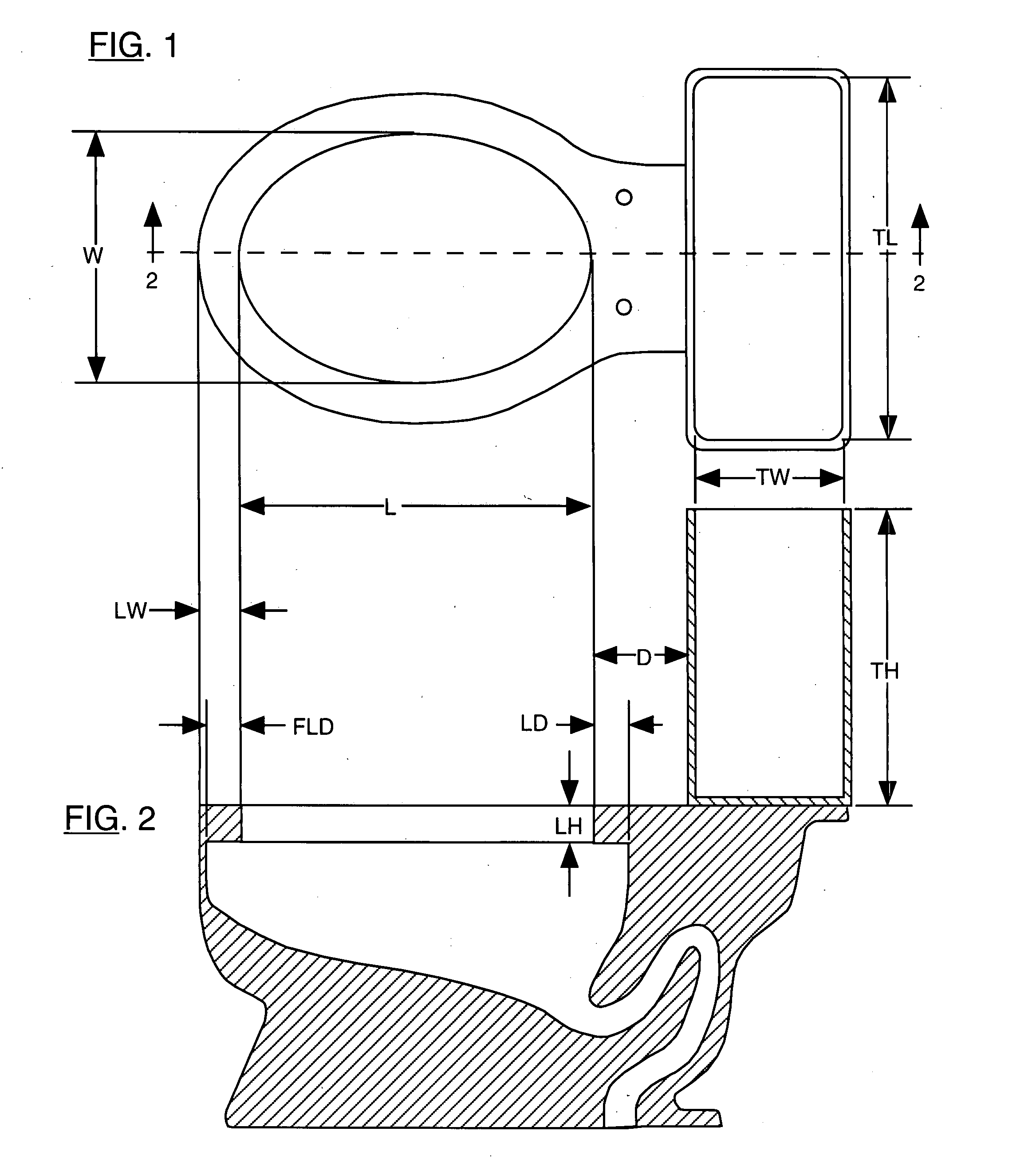

[0137]The dimensions used for an actual sample toilet bowl are: A=17.75″, B=13.5″ (FIG. 5). These are the dimensions for the elliptical shape of a toilet bowl rear lip's corner edge 7. A straight steel threaded rod having size 10-24 and 0.192″ in diameter (made by Steel Works), purchased from Lowe's Home Improvement, was used for this experiment. A 22.6″ length, which is half the calculated-circumference, was used to wedge at the rear end of said bowl (FIG. 18). An equal length from each end-of said threaded rod was progressively cut and reinstalled to check for holding power until said rod can no longer stay up on the bowl surface. The results are shown in the following table:

LENGTH CUTFINALHOLDING ONTOFROM EACH ENDLENGTHBOWL SURFACEStart length22.6″YES1.0″20.6″YES0.5″19.6″YES0.5″18.6″YES0.5″17.6″YES1.0″15.6″YES1.0″13.6″NO

The minimum length is calculated taking 13.6″ divided by the circumference of 45.2″ and is equaled to 30.0%.

example 2

[0138]FIG. 32 shows two ellipses representing an actual toilet bowl opening (smaller elliptical shape) and the bowl's lip underside rear corner edge 7 (larger elliptical shape). Said larger elliptical shape of lip's underside rear corner edge 7 obviously can not be seen visibly and is drawn from measured values. In order to insert a long and stiff member into the inside surface of the larger elliptical shape of said bowl, the long and stiff member must first pass through the small bowl opening and this requires minimally bending it as represented by member 75. After passing through the bowl's opening, the ends are released and are restraint by the inside surface represented by the larger ellipse. Said long and stiff member would assume the position of member 76 after its release, assuming that it has enough spring-back property to reach this position represented by H2=7.900″. If the member has higher spring-back property, it would still be restraint but it would have a built-in flex...

example 3

[0139]In this example, the preferred embodiment example of an integral long and slender member bidet assembly of this present invention shown in FIG. 28 was fabricated using only common commercially available tools and merchandise to demonstrate low manufacturing cost. Said bidet assembly was fabricated using: ¼″ OD and 0.218″ ID 304 stainless steel tubing, ¼″ ID and ⅜″ OD PVC (polyvinyl chloride) clear flexible tubing, and quick connect (push-to-connect) ¼″ OD tube “T” fittings (Watts, North Andover, Mass.)

[0140]The objectives of quick and easy installation in this present invention of a bidet assembly is demonstrated by timing the speed to install and to remove said fabricated bidet assembly from a toilet. A total of five trials of installation and removal were done. It is assumed that a user would first read an installation instruction prior to actual installation. Therefore, the recorded time is the actual time to install and remove, not counting the time to read the instruction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com